Method for monitoring lubricant distribution system and lubricant distribution system using same

A distribution system and lubricant technology, which is applied in the direction of engine lubrication, distribution devices, lubricating parts, etc., can solve the problems of many oil circuit connections, easy aging oil leakage, and few oil circuit connection ports, etc., to achieve intelligent detection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

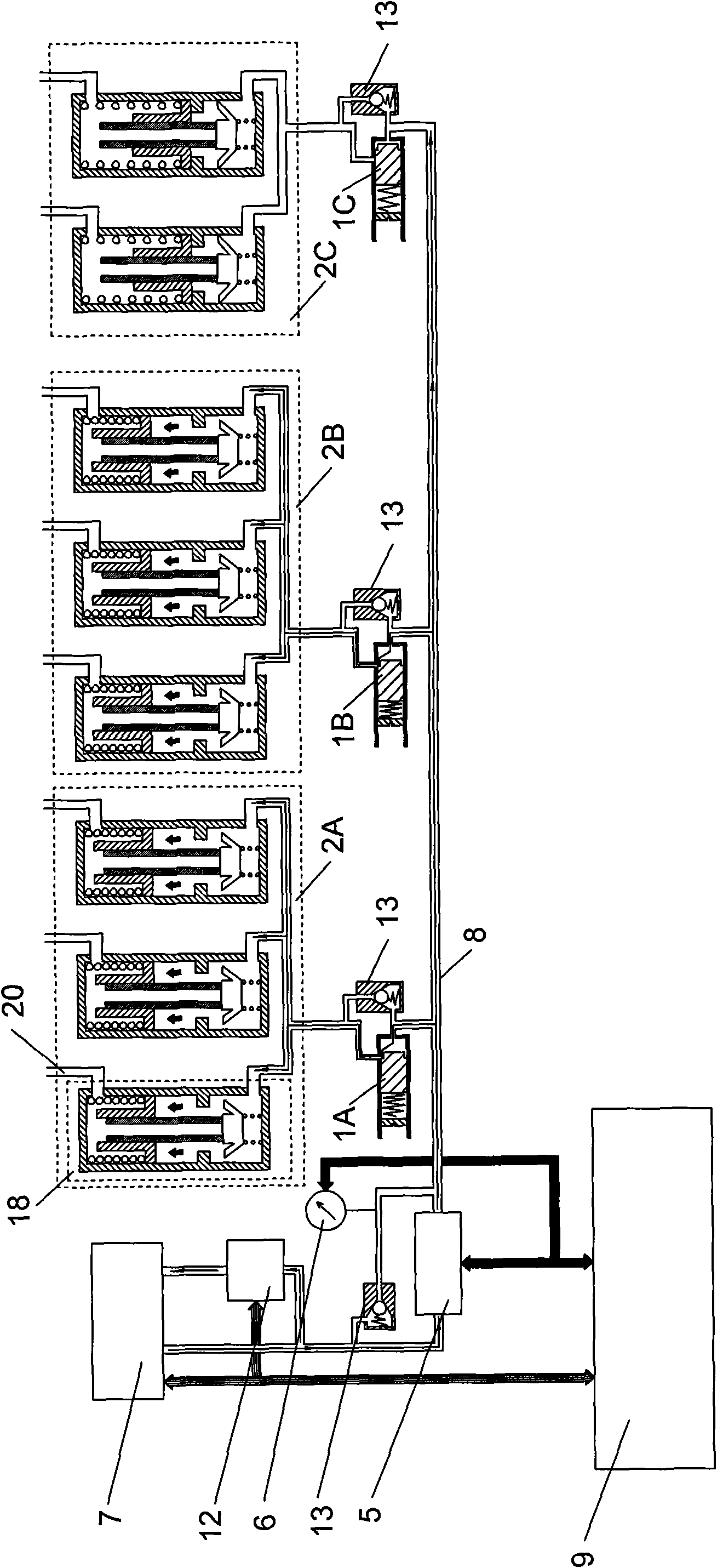

[0046] The monitoring method of the present invention means that a flow sensor and a pressure sensor I are arranged upstream of the distributor of the lubricant distribution system, and each distributor is connected with a pressure control valve with different parameter values. In this embodiment, the control fluid for controlling the pressure control valve is the lubricant itself, and the pressure control valve is a two-position two-way on-off type pressure control valve. When the pressure value of the lubricant output by the oil pump station 7 is greater than the opening pressure value of a certain pressure control valve connected to the distributor, the pressure control valve is opened, the oil supply pipe 8 and the inlet of the distributor are connected, and the lubricant is distributed from the When the output pressure of the oil pump station continues to increase, the pressure control valves with greater pressure parameters are opened one after another. Conversely, when ...

Embodiment 2

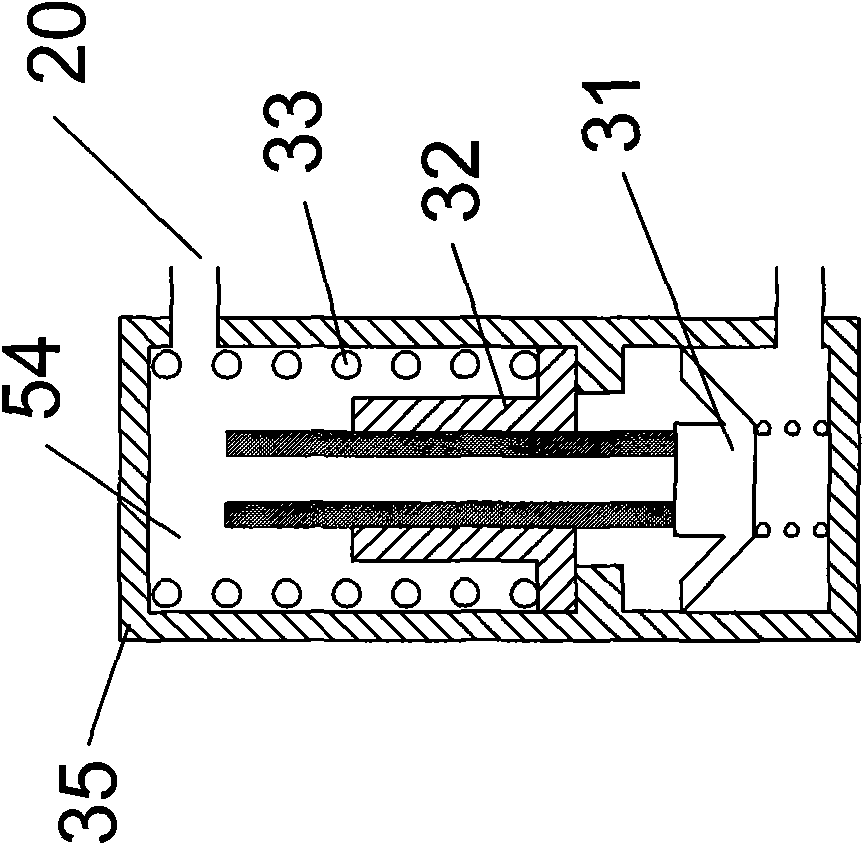

[0057] Such as Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that in this embodiment, the distributors in the lubricant distribution system are divided into two groups: the first group includes three distributors 2A, 2B, 2C, and the second group includes Two distributors 2D, 2E, each distributor in the second set is equipped with a pressure control valve 1D, 1E. In this embodiment, each distributor still adopts a single-line volumetric distributor, the first group of distributors is the same as that described in Embodiment 1, and in the second group of distributors, each distributor includes three volume units 18 , each volume unit 18 is also of 5ml specification, that is, during one oil pressure rise process, each volume unit 18 outputs 5ml of lubricant to the corresponding outlet 20 .

[0058] In addition, a flow sensor and a pressure sensor are arranged upstream of each group of distributors, and the output end of the flow sensor is connect...

Embodiment 3

[0063] The difference between this embodiment and Embodiment 1 is that in this embodiment, a plurality of two-position two-way on-off pressure control valves are respectively located at the outlets of the distributors 2A, 2B, and 2C, and the distributors 2A, 2B, and 2C have Eight outlets, so a total of eight pressure control valves are required. In this way, when the pressure value output by the oil pump station 7 is greater than the rated pressure value of the pressure control valve of the corresponding lubrication point, the pressure control valve can be opened, so that the lubricant flows out to the lubrication point through the volume unit and the pressure control valve.

[0064] The continuous casting machine uses this lubricant distribution system. Generally, the distributor of each working section is a group, and the corresponding flow sensor and pressure sensor are matched.

[0065] Other technical characteristics are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com