Method for preparing aluminum-based composite material plate by friction stir

An aluminum-based composite material and friction stir technology, which is applied in the field of friction stir preparation of aluminum-based composite materials and achieves the effect of simple process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

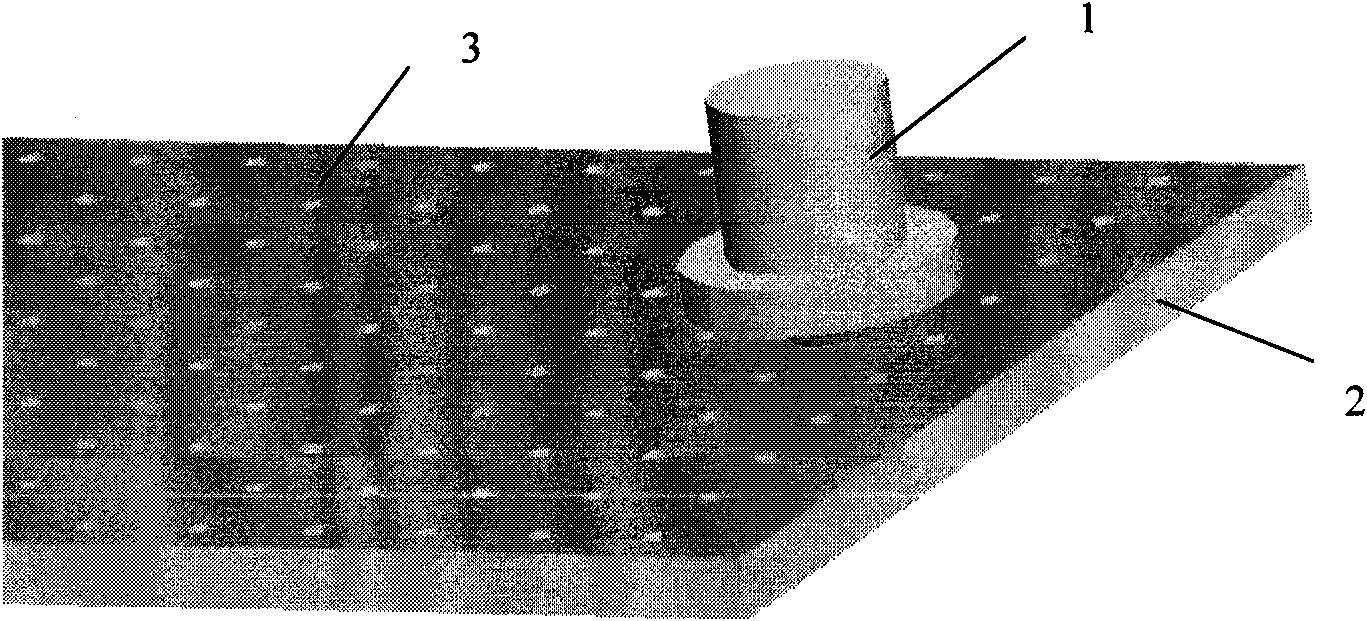

[0016] The friction stir preparation method of the aluminum-based composite material plate of the present embodiment comprises the following steps: 1. uniformly forming several circular holes with a diameter of 1-5 mm on a base material aluminum plate (pure aluminum plate) with a thickness of 2 mm, Mix titanium powder with a particle size of 30-100 microns in advance with alcohol, grind and stir it into a paste, and then place it in the small hole to form an intermediate plate; ② sandwich the intermediate plate with the base material A composite sheet is formed between surface aluminum sheets with the same composition and specifications of the aluminum sheets; ③ performing friction stir treatment on the composite sheet with a stirring head of a friction stir welding machine to obtain an aluminum matrix composite sheet. Preheating may also be performed prior to the friction stir treatment. During the friction stir treatment, the rotation speed of the stirring head was 800 rpm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com