Method for applying ultrafiltration technology to proportion standardization of protein and fat in cheese processing

An application method and fat technology, applied in the fields of application, cheese substitutes, dairy products, etc., to achieve the effects of increasing production, reducing pollution, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: (the application method of ultrafiltration technology in cheese processing protein fat standardization)

[0018] Raw milk is standardized after acceptance and purification. Skim milk is mixed with a certain proportion of raw milk to adjust the ratio of protein and fat. The ratio of protein / fat is adjusted to be between 0.69 and 2.8. Consider mixing skim and whole milk in different ratios: 0:8, 2:6, 4:4, 6:2, 8:0. Sterilize by pasteurization at 72°C for 15sec, cool to 30-32°C, and pour into the cheese tank that has been sterilized in advance. For the addition of starter and rennet, when the milk temperature is at 32°C, a starter with 1% to 2% of raw milk is added. After adding the starter and stirring evenly, add CaCl with 0.01% to 0.02% of raw milk 2 , to be added slowly and evenly. Leave to ferment for 30-40 minutes, and when the acidity reaches 0.18%-0.20%, add 0.002% rennet, stir and curd the milk. Cutting, heating and stirring and removing whey, th...

Embodiment 2

[0019] Embodiment 2: (the application method of ultrafiltration technology in cheese processing protein fat standardization)

[0020] Ultrafiltration technology is used to increase the solid content of milk raw materials, and the concentrated milk is 0.5 times the volume of the original milk. The operating pressure of ultrafiltration is 0.05-0.08MPa, and the operating temperature is 4-8°C.

[0021] Raw milk is standardized after acceptance and purification, and mixed with ultra-filtered concentrated milk and a certain proportion of raw milk, the ratios are as follows: 0:8, 2:6, 4:4, 6:2, 8:0. Sterilize by pasteurization at 72°C for 15sec, cool to 30-32°C, and pour into the cheese tank that has been sterilized in advance. The addition of starter and rennet, when the milk temperature is 32°C, add raw materials

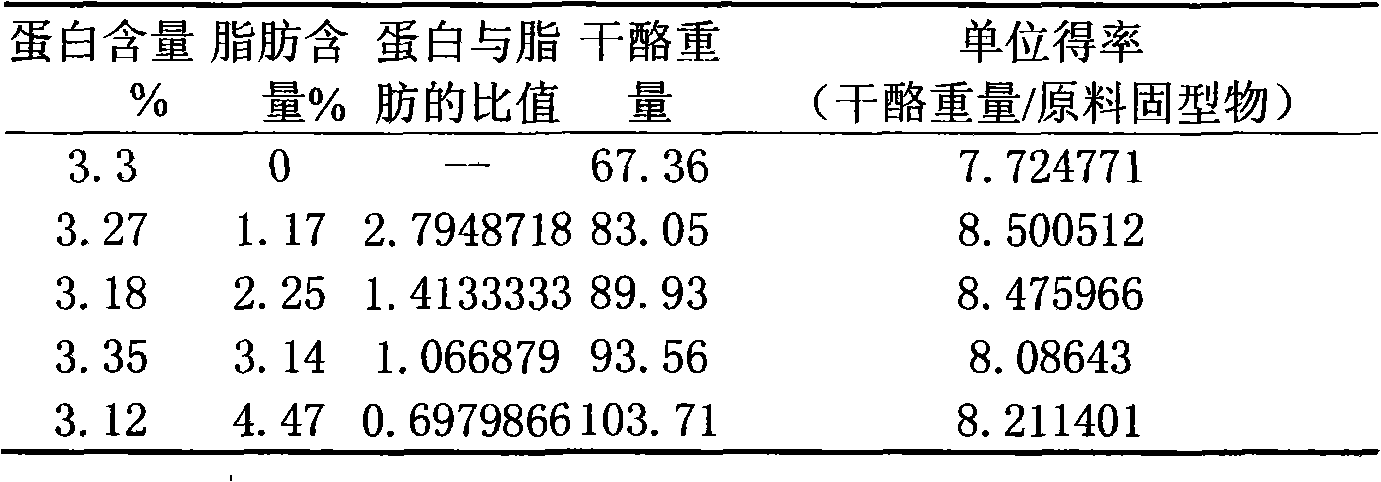

[0022] Table 1, the effect of different ratios of skim milk and whole milk on cheese yield

[0023]

[0024] A starter with 1% to 2% milk. After adding the starte...

Embodiment 3

[0027] Embodiment 3: (the application method of ultrafiltration technology in cheese processing protein fat standardization)

[0028] The skimmed milk (fat2, to be added slowly and evenly. Leave to ferment for 30-40 minutes, and when the acidity reaches 0.18%-0.20%, add 0.002% rennet, stir and curd the milk. Cutting, heating and stirring and removing whey, the curd cutting size is 0.5-0.8cm; heating and stirring at a speed of 1°C every 6 minutes. Stop heating when the temperature finally rises to 38-39°C, and stir when the acidity of the whey reaches about 0.20%, get rid of all the whey. The production processes such as adding salt and forming are as described in the technical solution in the summary of the invention. Experimental results Table 3 shows that after adding in proportion, the unit yield of skimmed thick milk is higher when the ratio of protein and fat is adjusted from 0.89 to 1.0, and the unit yield is 9.479 when the ratio is 1.0.

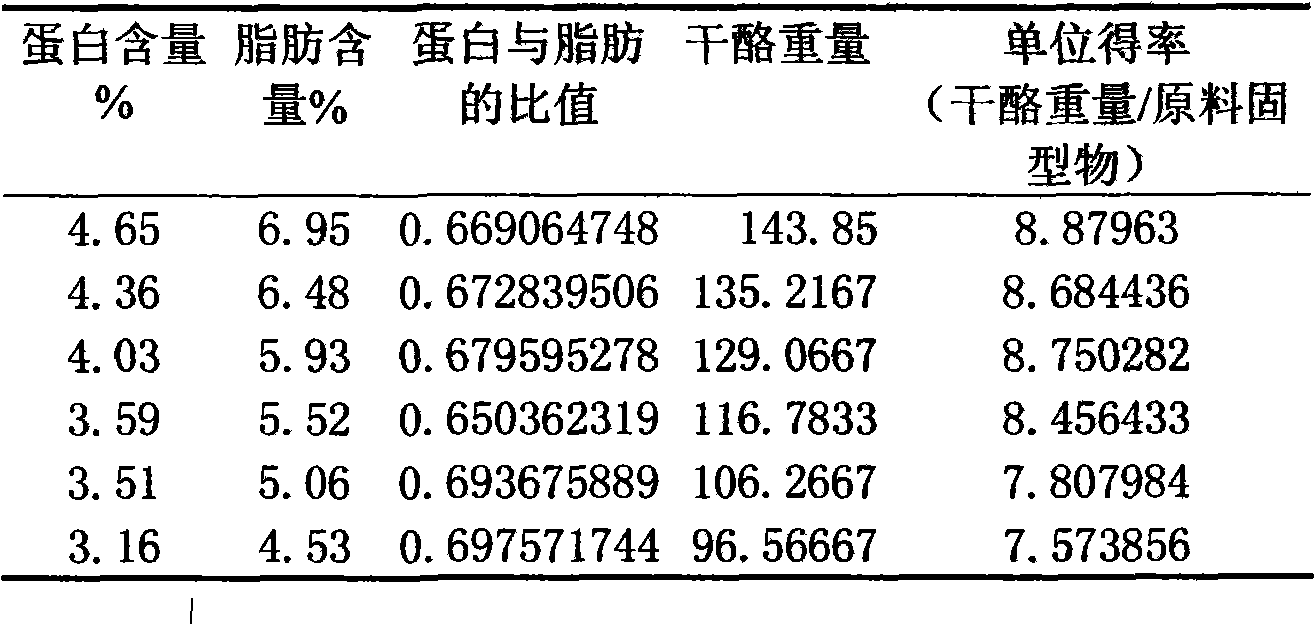

[0029] Table 3, the effect o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com