Combustion engine island technique

A process method and gas turbine technology, applied in gas turbine devices, fuels, gas fuels, etc., can solve the problems of high pollutant emission, high combustion safety, co-generation and complex IGCC systems, and achieve low NOx emissions, reduced power consumption, The effect of improving system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

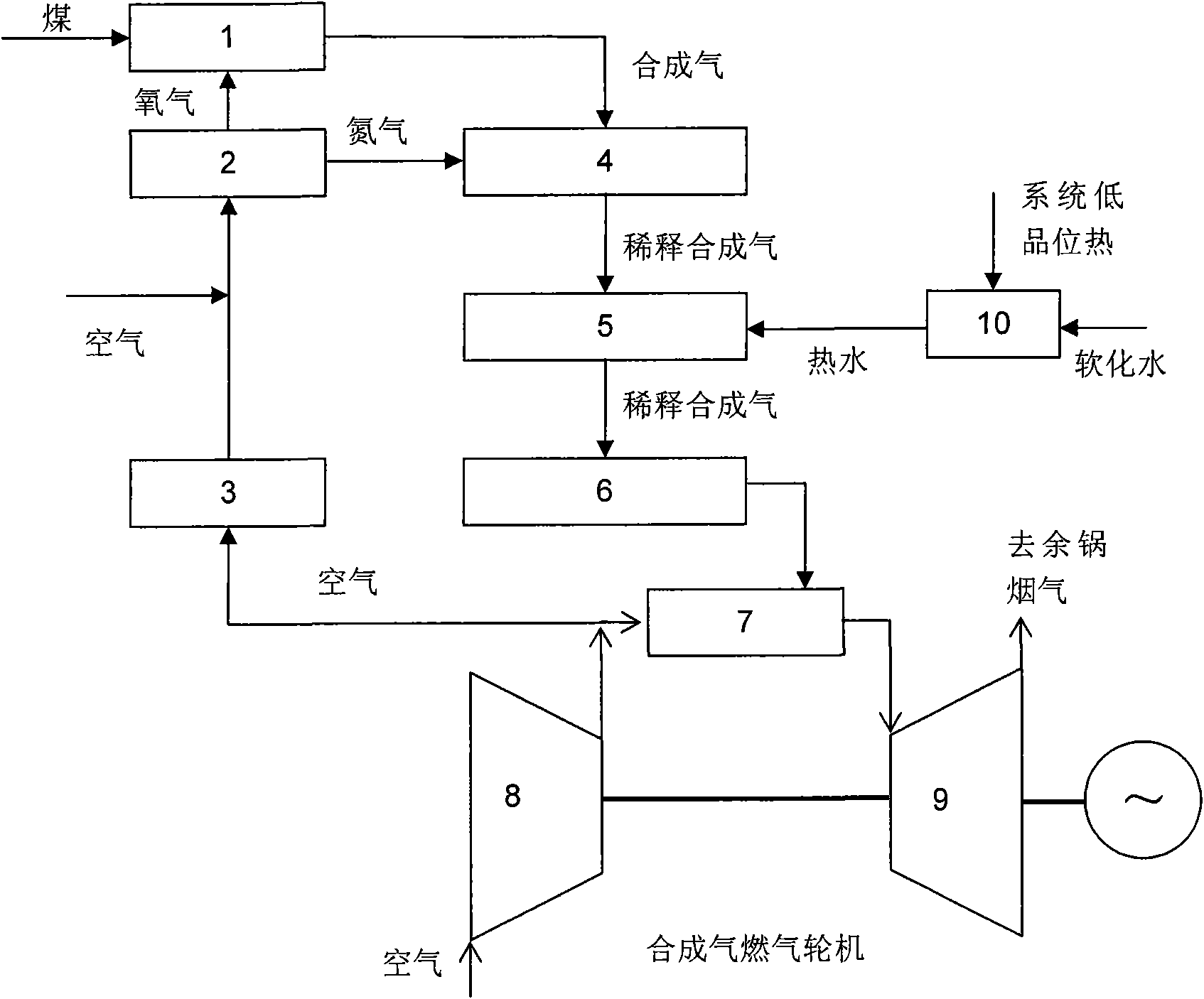

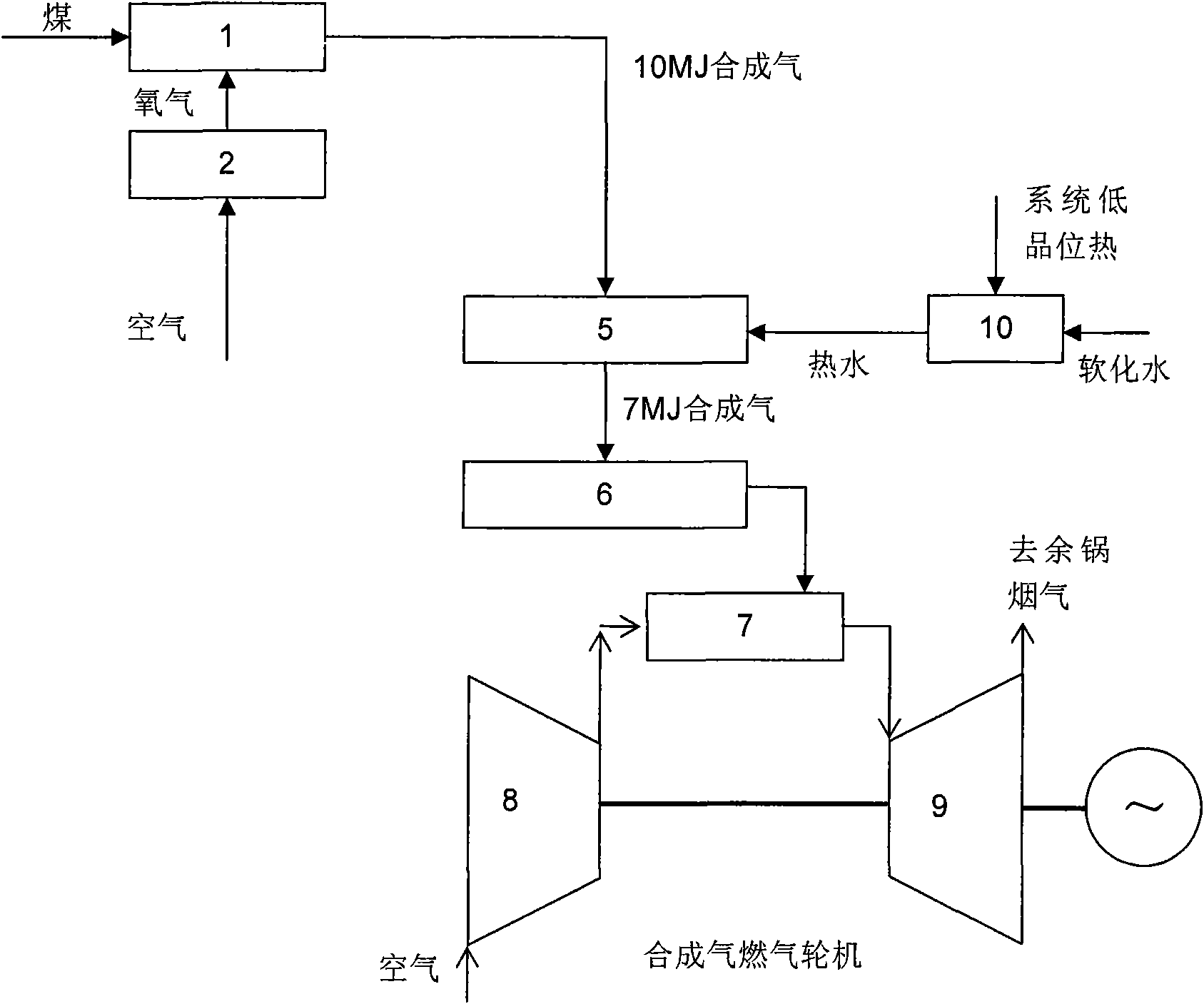

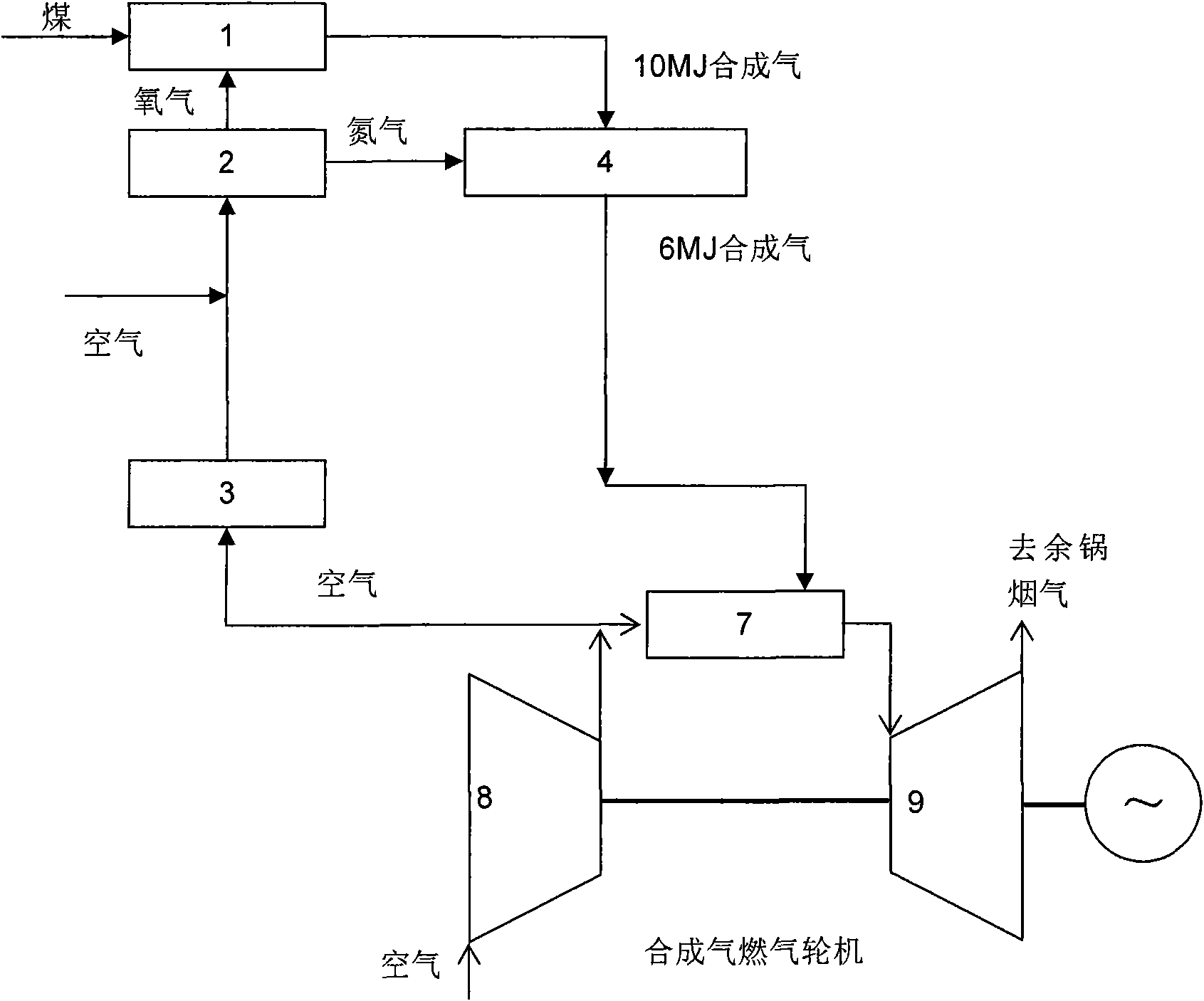

[0026] See attached figure 1 , is a schematic flow chart of the gas turbine island process method of the present invention, which includes a syngas gas turbine (composed of a compressor 8, a combustion chamber 7 and a turbine 9), a syngas dilution supply scheme (gasifier 1, blender 4 , humidifier 5, superheater 6 and heat exchanger 10), gas turbine compressor air extraction utilization scheme (air separation 2, cooler 3).

[0027] The gas turbine island process flow of the present invention is described as follows:

[0028] like figure 1 The syngas gas turbine shown includes a compressor 8, a combustor 7, and a turbine 9. After being compressed by the compressor 8, most of the air enters the combustor 7, and part of it enters the cooler 3 for waste heat utilization and then supplies the air separation unit 2. The combustor 7 The high-temperature and high-pressure gas after the combustion of the air and the syngas enters the turbine 9 to expand and do work, driving the genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com