Method for preparing nano materials by direct electrodeposit in ionic liquid microemulsion

A technology of ionic liquid and microemulsion, which is applied in the field of direct electrodeposition to prepare nanomaterials in ionic liquid microemulsion, which can solve the problems of poor conductivity, difficult electrochemical research, and few electrochemical methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

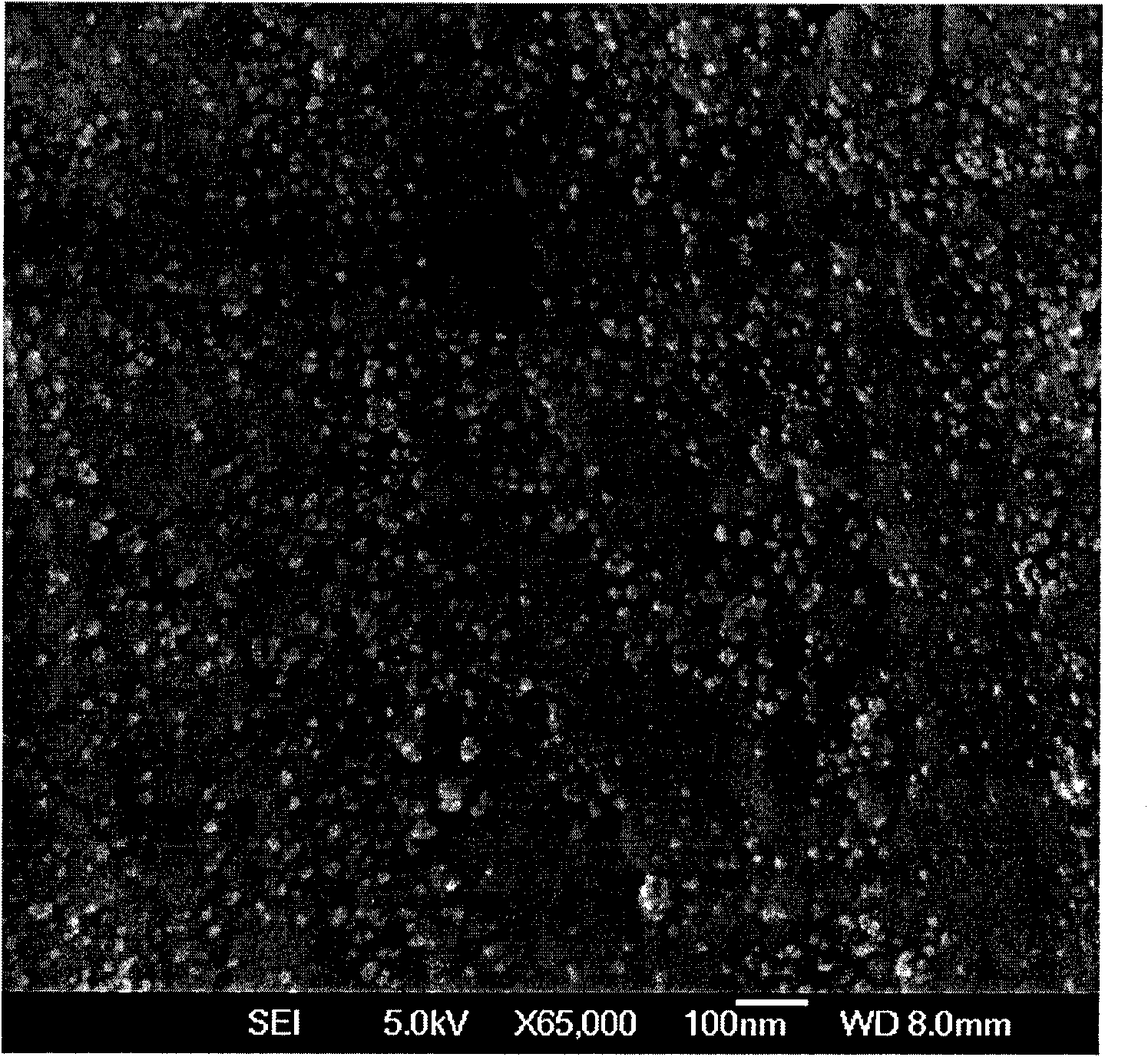

Embodiment 1

[0025] The 0.05 mol / L silver nitrate aqueous solution, the surfactant polyethylene glycol octyl phenyl ether and the 1-butyl-3-methylimidazole hexafluorophosphate ionic liquid were adjusted to 10%, 45%, and 45% volume respectively Ratio mixing, and then ultrasonic for 10min to make the mixing uniform. The glassy carbon electrode with a diameter of 3mm was polished smoothly on the ultrafine alumina powder, washed with water, and then placed in a diluted nitric acid aqueous solution, anhydrous ethanol and double distilled water, respectively, and sonicated for 5 minutes, and dried for use. Then connect the glassy carbon as the working electrode to the negative electrode of the power supply, and the large-area platinum plate as the counter electrode to the positive electrode of the power supply, put it into the pre-prepared ionic liquid microemulsion containing silver nitrate, and control the current density to 5mA / cm 2 , After 5 minutes of deposition, the desired coating can be obta...

Embodiment 2

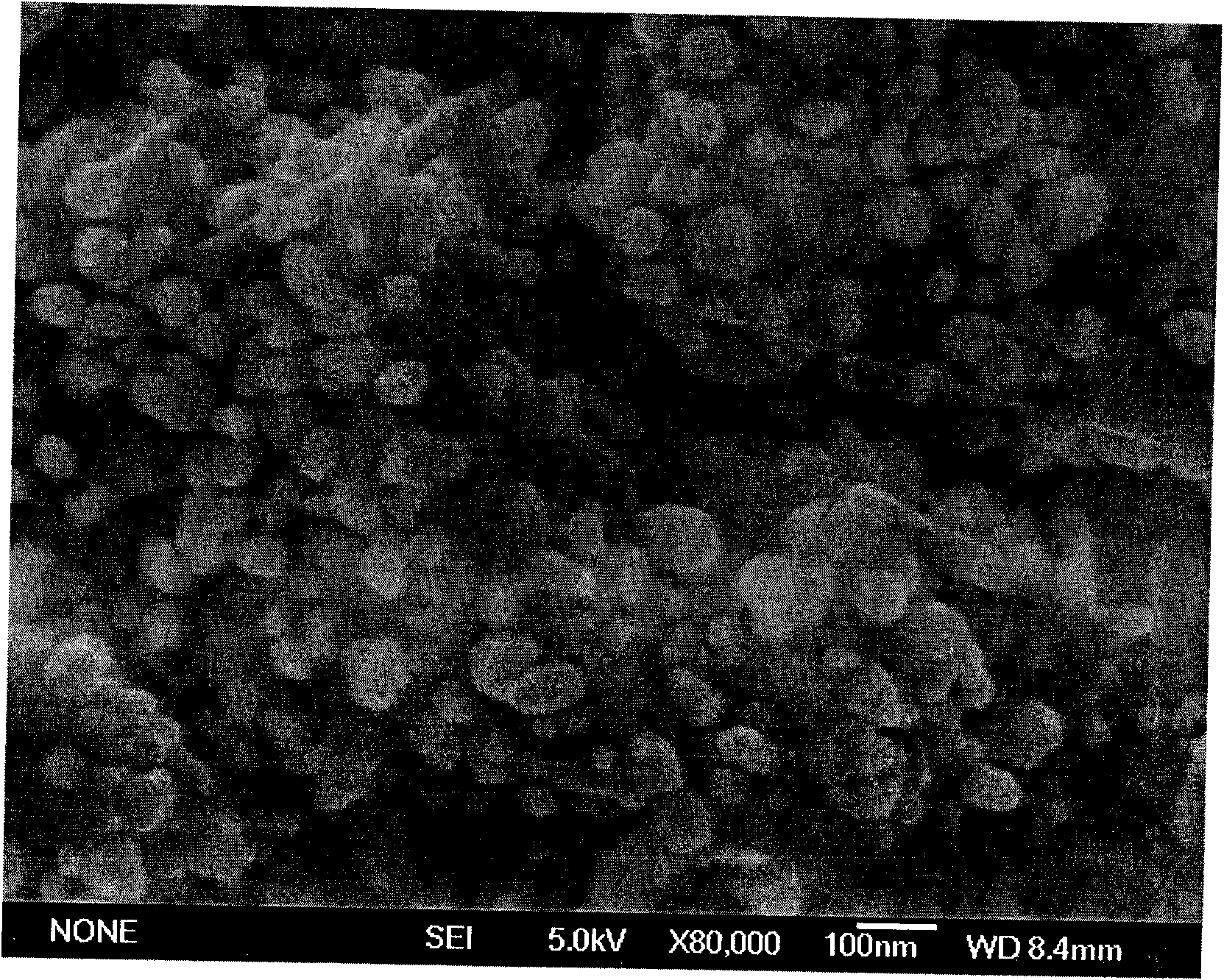

[0027] The 0.01 mol / L chloroauric acid aqueous solution, the surfactant polyethylene glycol octyl phenyl ether and the 1-butyl-3-methylimidazole hexafluorophosphate ionic liquid were adjusted to 10%, 55%, and 35% respectively The volume ratio is mixed, and then sonicated for 10 minutes to make it uniform. At the same time, the surface area is 0.5cm 2 The stainless steel electrode is polished on the ultrafine alumina powder to a mirror surface, washed with water, and then placed in a diluted nitric acid aqueous solution, anhydrous ethanol and double distilled water, respectively, and ultrasonicated for 5 minutes, and dried for use. Then use stainless steel as the working electrode, large-area platinum sheet as the counter electrode, and anhydrous Ag / AgCl as the reference electrode, put it into the pre-prepared ionic liquid microemulsion containing chloroauric acid, control the electrode potential to 0.2V, and deposit After 30 minutes, the desired coating can be obtained on the stai...

Embodiment 3

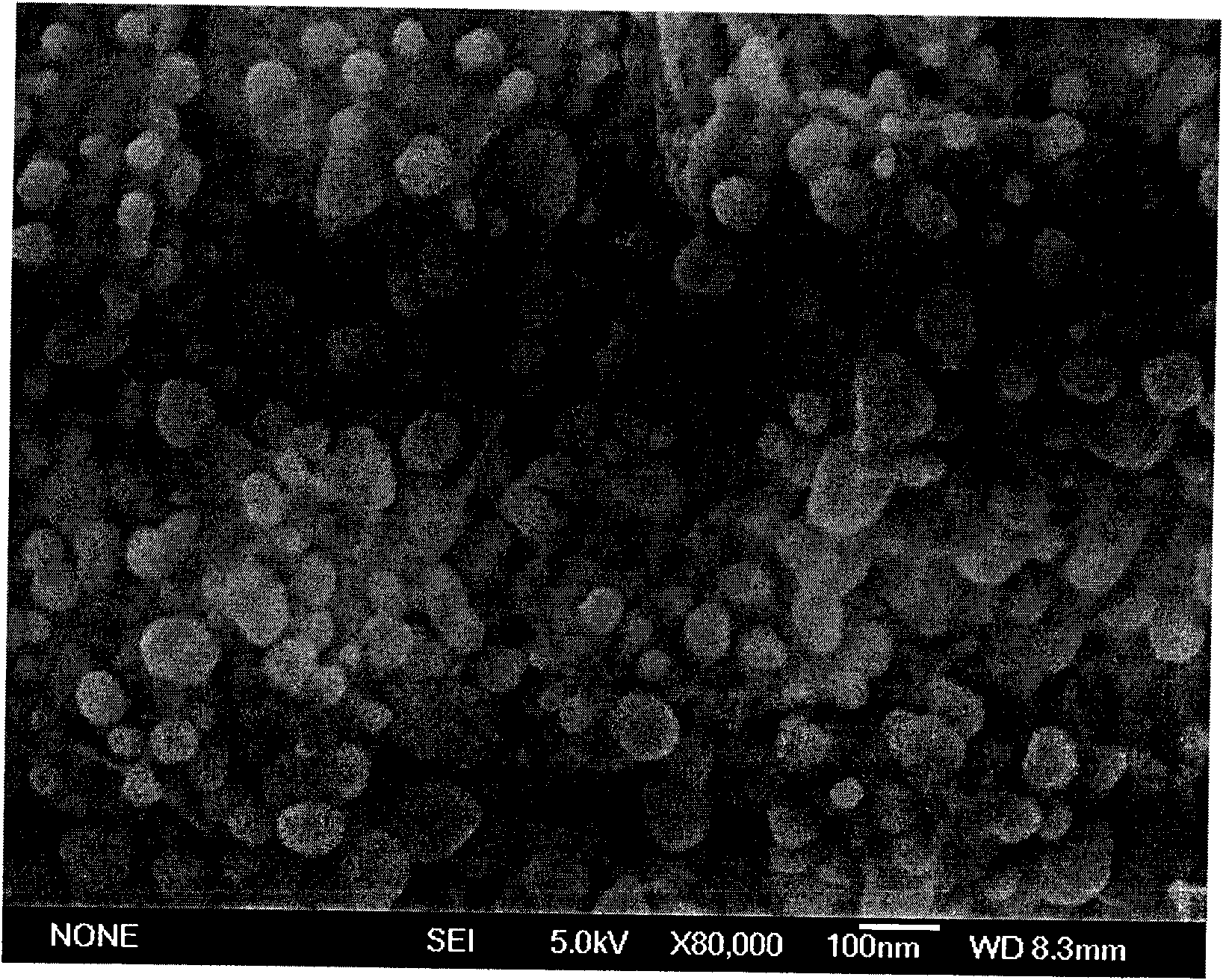

[0029] Mix 0.1 mol / L chloroauric acid aqueous solution, surfactant polyethylene glycol octyl phenyl ether and 1-butyl-3-methylimidazole hexafluorophosphate ionic liquid in a certain volume ratio to prepare three Part of the microemulsion with different molar ratios of water and surfactant, the molar ratios of which are 5.25, 7.7, and 9.0 respectively, and then sonicated for 10 minutes to make it uniform. At the same time, the surface area is 0.5cm 2 The nickel electrode is polished brightly on metallographic sandpaper, washed with water and placed in absolute ethanol and double-distilled water for 5 minutes each, and dried for use. Then connect the nickel electrode as the working electrode to the negative electrode of the power supply, and the large-area platinum sheet as the counter electrode to connect the positive electrode of the power supply, and put it into three pre-prepared ionic liquid microemulsions containing chloroauric acid with different molar ratios of water and sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com