Method of separation of soap and water

A separation method and soapy water technology are applied in the field of soapy water separation in the edible oil industry to achieve the effects of reduced utilization, less acid consumption and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

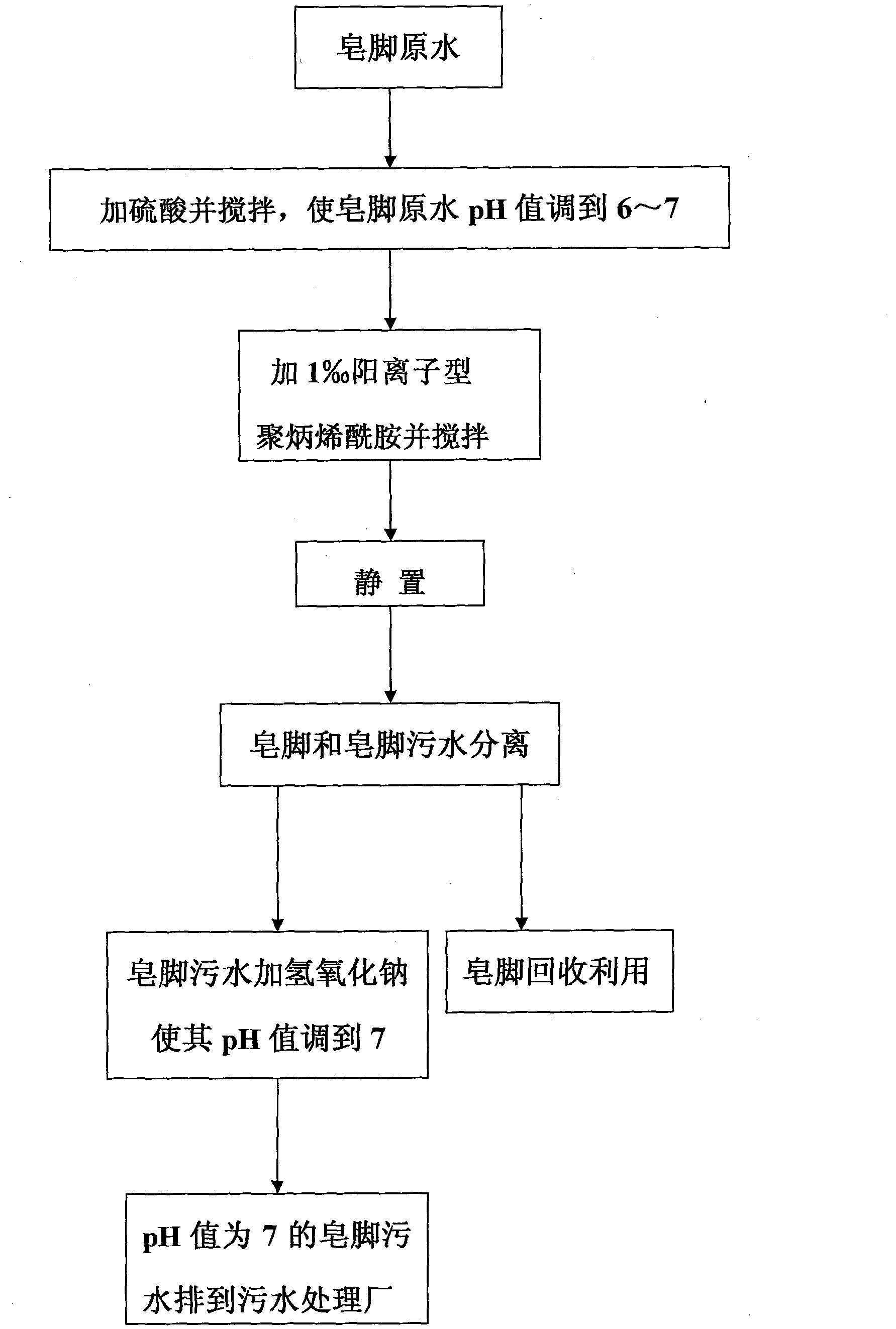

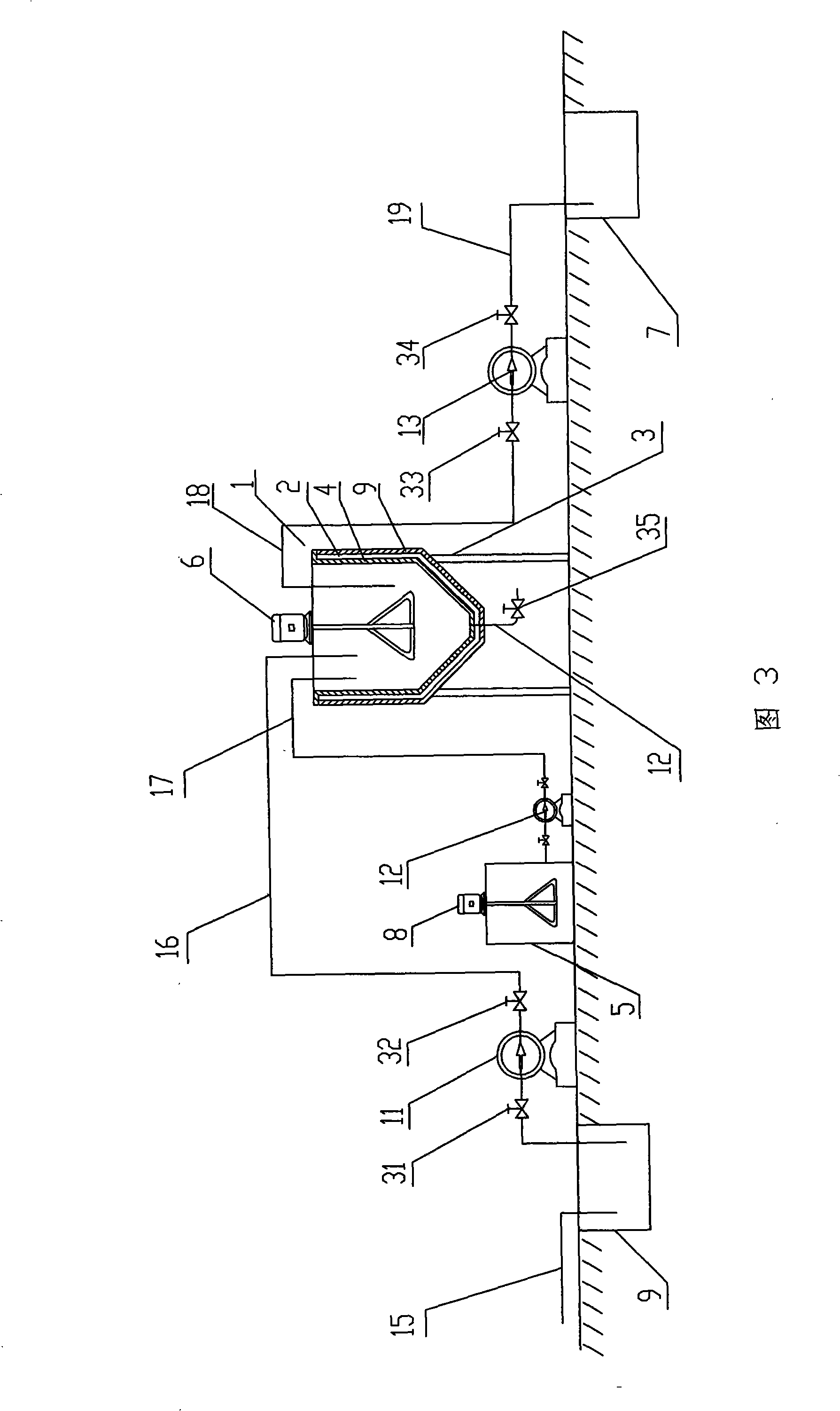

[0049] A kind of soapy water separation method 1 embodiment:

[0050] Such as figure 1 with image 3 As shown, use the screw pump 11 to pump 1000 kg of soapstock raw water from the soapstock raw water pool 9 to the heating and stirring tank 1, and the temperature of the heating and stirring tank 1 is kept between 60°C and 65°C. At this time, the pH of the soapstock raw water is measured to be 12 15 liters of sulfuric acid of 25% concentration are loaded into the dosing tank 5, the metering pump 12 is opened, the flow control is at 270 milliliters / second, and the time needs 40 seconds, then change the micro-acid addition to adjust the pH value; add sulfuric acid Start stirring at the same time, the stirring speed is controlled at 20 rpm, add sulfuric acid while stirring, observe the reaction of soapstock raw water and measure the pH value at the same time, when the pH value is adjusted to between 6 and 7 (slightly acidic), stop adding Sulfuric acid, at this moment very small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com