Integrated silicon chip for testing acceleration, pressure and temperature, and manufacturing method thereof

A silicon chip and acceleration technology, used in the measurement of acceleration, speed/acceleration/shock measurement, thermometer, etc., can solve the problems of temperature drift, difficult to miniaturize, and the device cannot work, and achieves good accuracy, good stability, and high sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The substantive features and remarkable progress of the present invention will be further described below through specific implementation, but the present invention is by no means limited to the described embodiments.

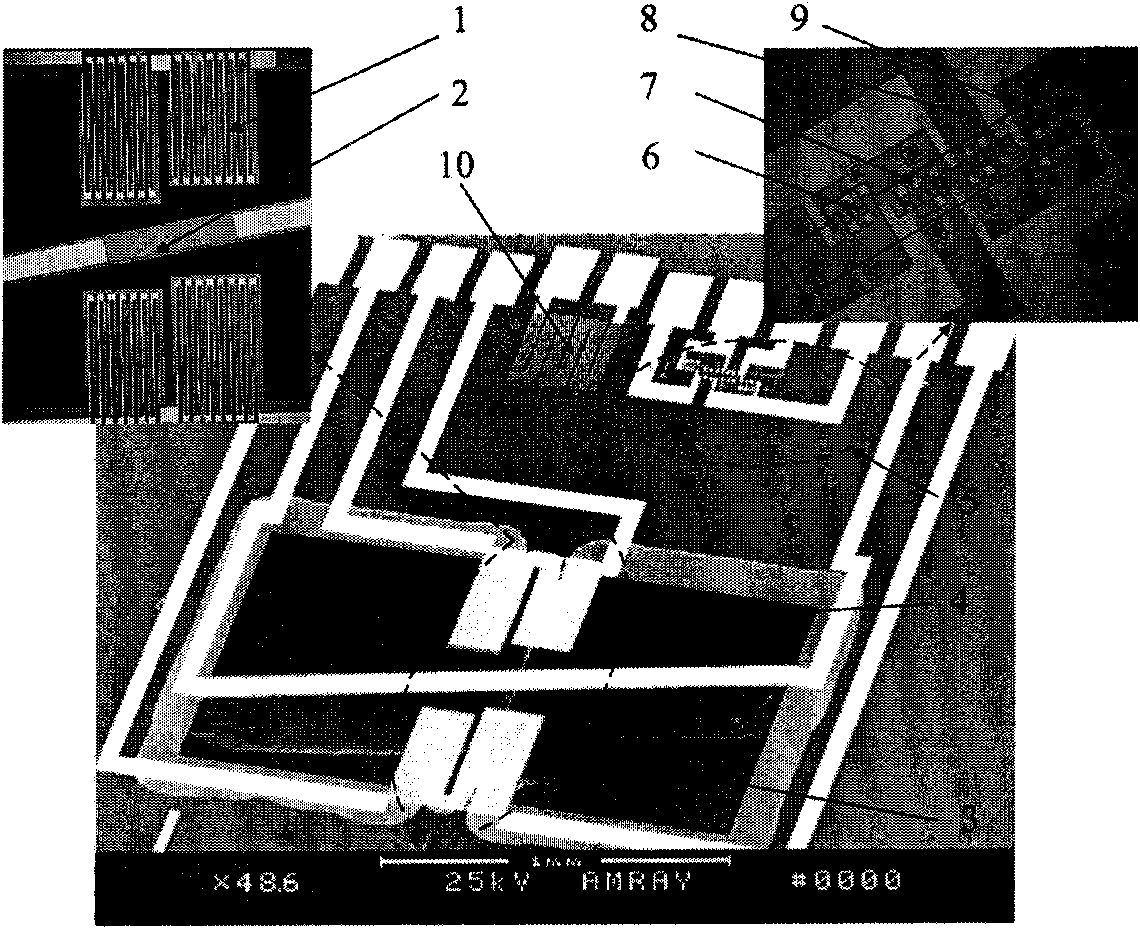

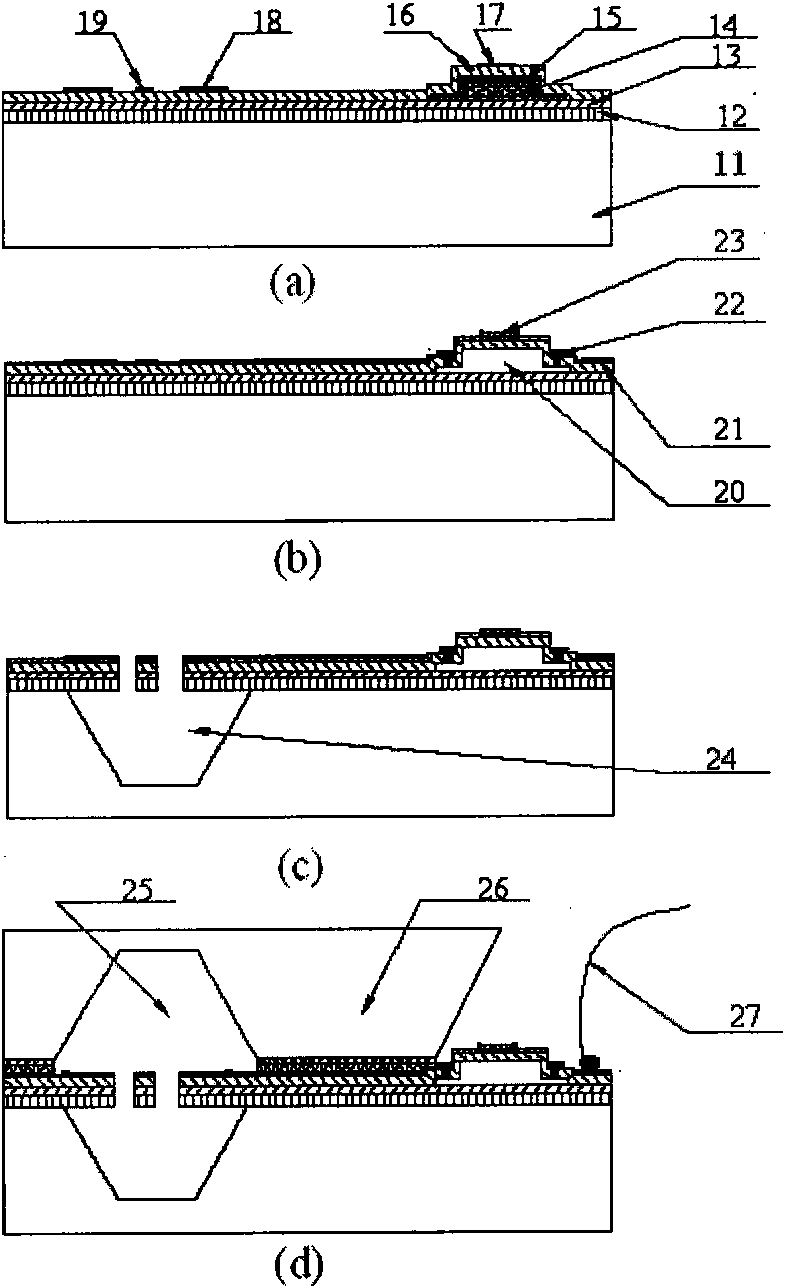

[0019] like figure 1 Shown is an integrated silicon chip and its manufacturing method for testing acceleration, pressure and temperature. The scanning electron microscope photo of the graphic surface before bonding is inserted in the upper left corner for the heating resistor and temperature detection thermopile of the accelerometer. , and the upper right corner is a magnified view of the pressure sensor. The thickness h of the designed LS SiN structure layer is 1.2 μm, the polysilicon thin film forms a force sensitive resistor with a thickness of 0.3-0.6 μm, and the sacrificial layer thickness is 2 μm.

[0020] Concrete process implementation steps are as follows:

[0021] 1. Construct the sacrificial layer, define the polysilicon force sensitive res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com