Split type Stirling refrigerating machine

A refrigerator, a separate technology, used in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of the decline of the refrigeration capacity of the refrigerator, the failure of the refrigerator, and the failure, so as to improve the service life and reliability, improve the radial The effect of positioning ability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the technical solution of the present invention, the specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings:

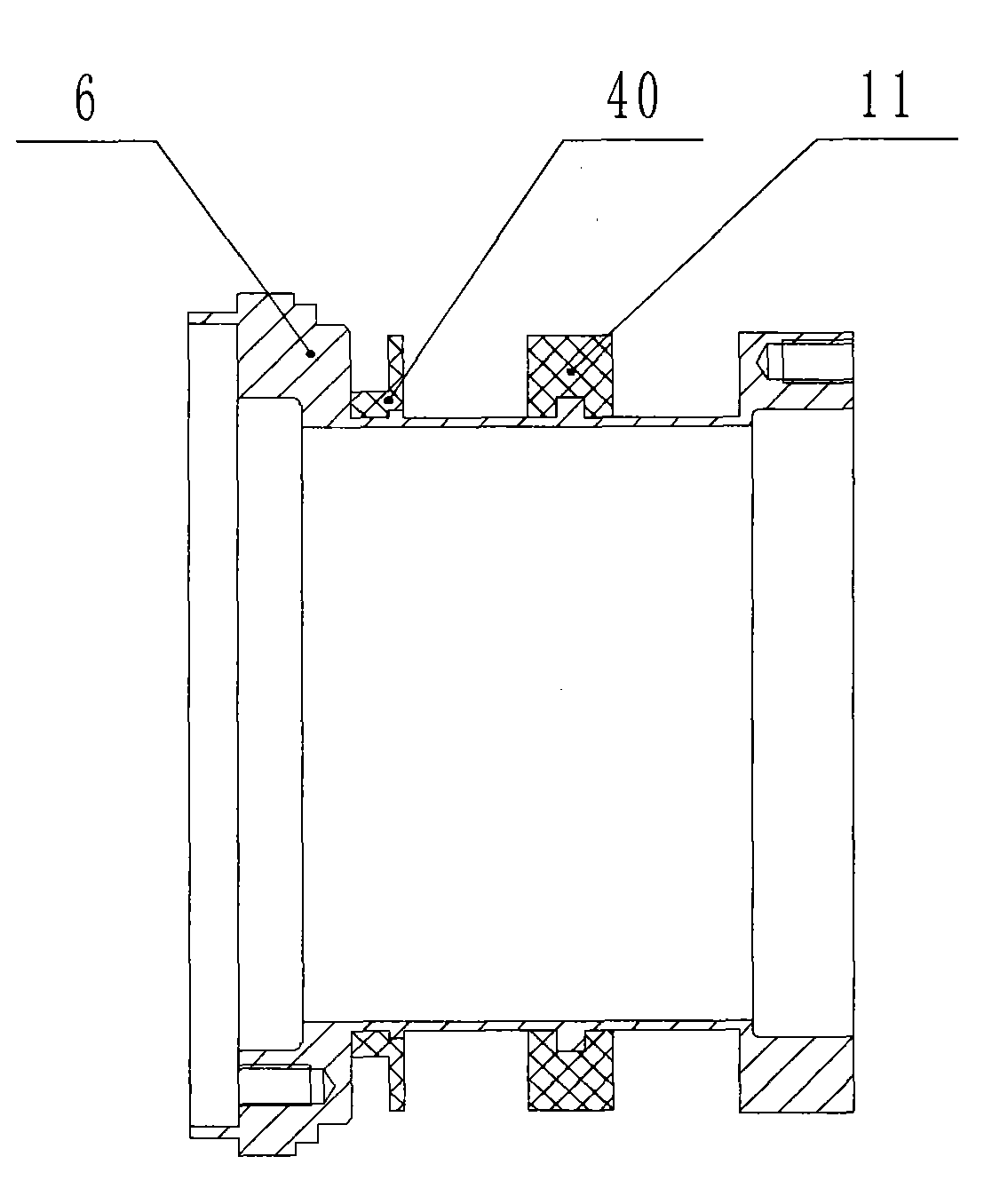

[0019] Such as figure 1 , separated by the metal hose connecting pipe 26, the lower part is the compressor, and the upper part is the expander.

[0020] The compressor includes moving magnet linear motor, diaphragm spring, compression piston, compression cylinder, compressor end cover and other components.

[0021] The moving magnet linear motor includes a magnetic steel 13 , an inner magnetic pole 9 , a mover support 8 , an outer magnetic pole 14 , a coil support 6 and a coil 12 . The magnetic steel 13 is two sets of magnetic steel components with opposite polarities. Each set of magnetic steel components is composed of 12 pieces of tile-shaped magnetic steel. The magnetic steel 13 is fixed on the outer surface of the inner magnetic pole 9 with glue, and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com