Connection structure of waveform plastic conduit, a waveform plastic conduit used by the connection structure and manufacture method thereof

A technology of synthetic resin and connection structure, which is applied in the direction of pipeline connection arrangement, pipe/pipe joint/fitting, hose, etc., which can solve the problems of water resistance, pressure resistance limitation, and operation efficiency limitation, so as to achieve sufficient water resistance and easy connection operation , the effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] Next, embodiments of the present invention will be described in detail with reference to the drawings.

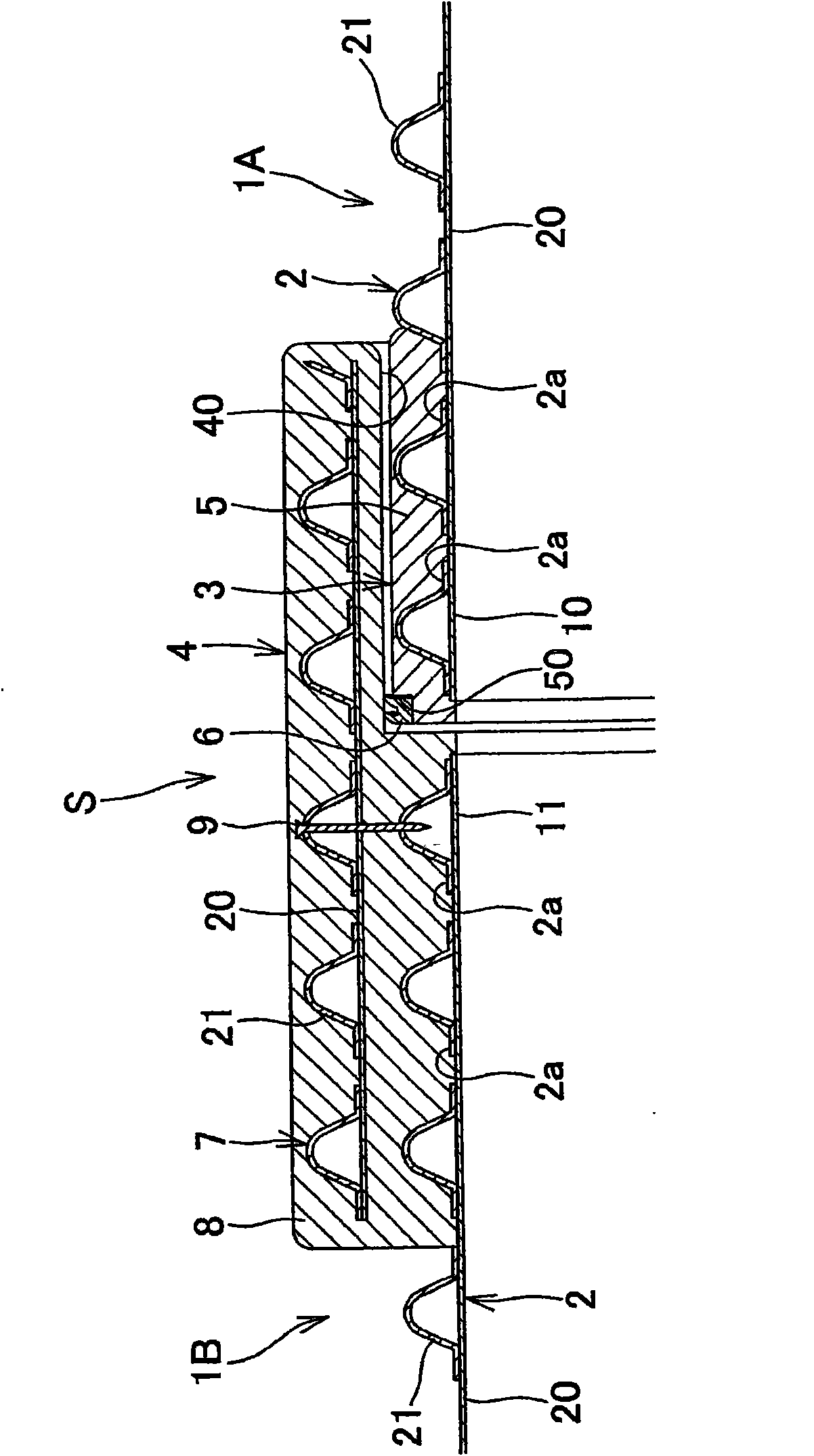

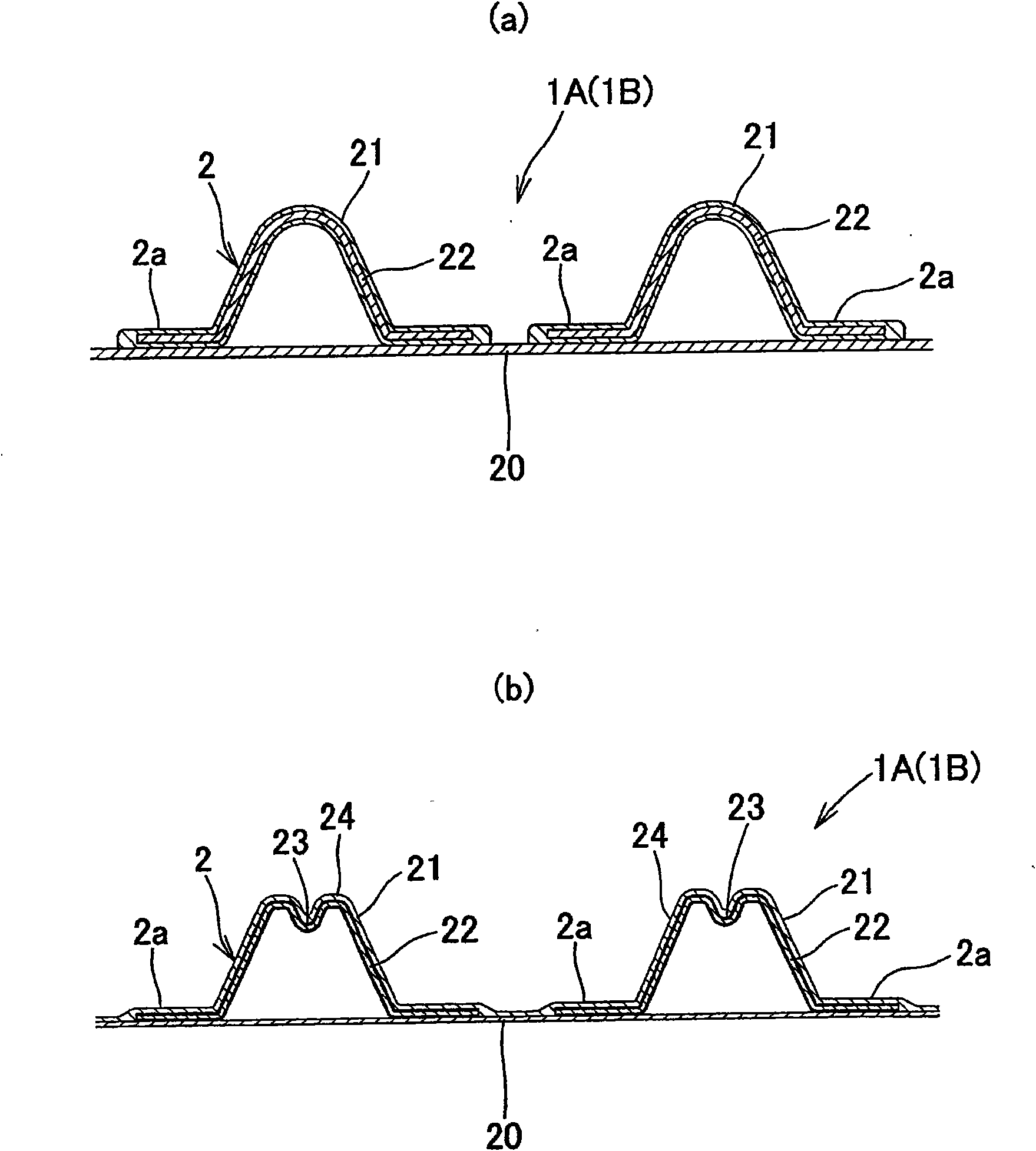

[0083] figure 1 It is an explanatory diagram showing the connection structure S of corrugated synthetic resin tubes 1A, 1B according to the present invention, Figure 1~4 Showing the first embodiment of the present invention, Figure 5 , 6 shows the second embodiment, Figure 7 , 8 Indicates the third embodiment, Figures 11-16 The fourth embodiment is shown, and symbols 1A, 1B, and 1C in the figure indicate corrugated synthetic resin tubes, 2 indicates a tube wall, 3 indicates a socket portion, and 4 indicates a socket portion.

[0084] The connection structure S of the corrugated synthetic resin pipe of the present invention, such as figure 1 and figure 2 As shown, two corrugated synthetic resin tubes 1A, 1B are formed by connecting the tube wall 2 to a spiral corrugation with the ends connected to each other. In the present embodiment, the corrugated synt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com