Aqueous suspension bearings

A suspension bearing and water suspension technology, applied in the field of bearings, can solve the problems such as the inability to meet the high-speed and high-precision requirements of the grinder, the difficulty of the spindle unit accuracy to meet the high-precision requirements, and the inability to meet the requirements of the high-speed grinder, etc., and achieve heat dissipation effect. Good, stable performance, beneficial to environmental protection and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

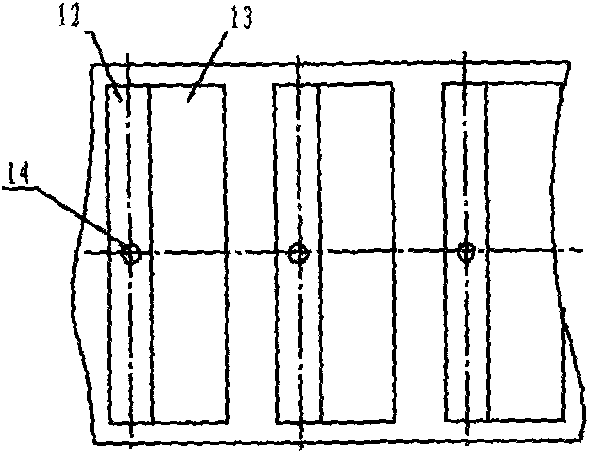

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

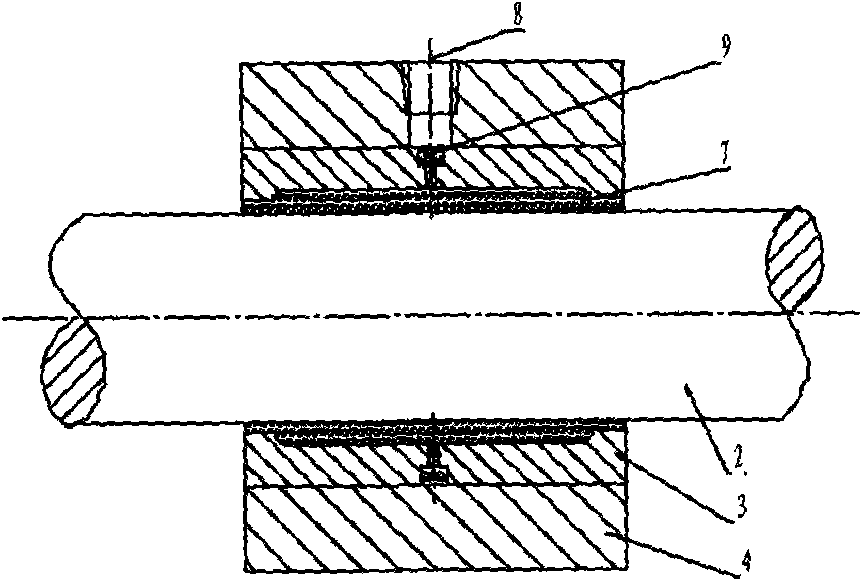

[0017] The present invention is developed on the basis of sliding bearings. The technical scheme of the present invention includes the following three aspects: 1. By means of a hydraulic system, water is forcibly sent between two relatively sliding bearing working surfaces, and the water is used to 2. Relying on the dynamic pressure generated when the main shaft rotates, the system has a greater bearing capacity and has high rotation accuracy, high rigidity, and vibration resistance. Good features; 3. Make full use of the small water-liquid friction coefficient and good heat dissipation, supplemented by refrigeration treatment to solve the cooling problem when the spindle is above 6000 rpm.

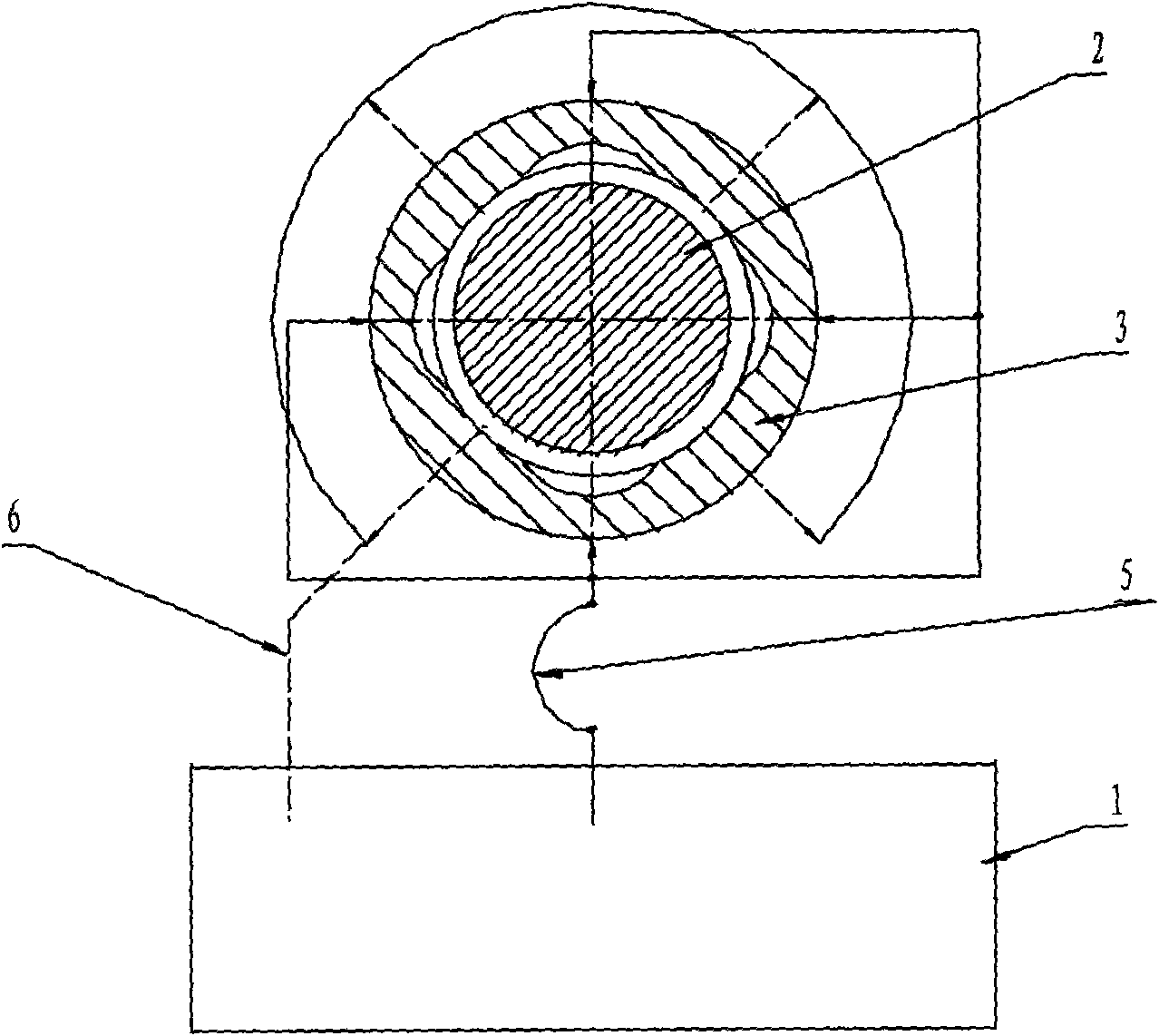

[0018] Such as figure 1 As shown, the present invention is composed of two parts, a water quality hydraulic station 1 and a suspension bearing unit, whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com