Automatic drainage control device of toilet bowl

An automatic drainage and control device technology, applied in the field of sanitary ware, can solve the problems of insensitivity, easy damage, inconvenience for users and managers, etc., and achieve the effect of reliable operation, convenient use and avoiding high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

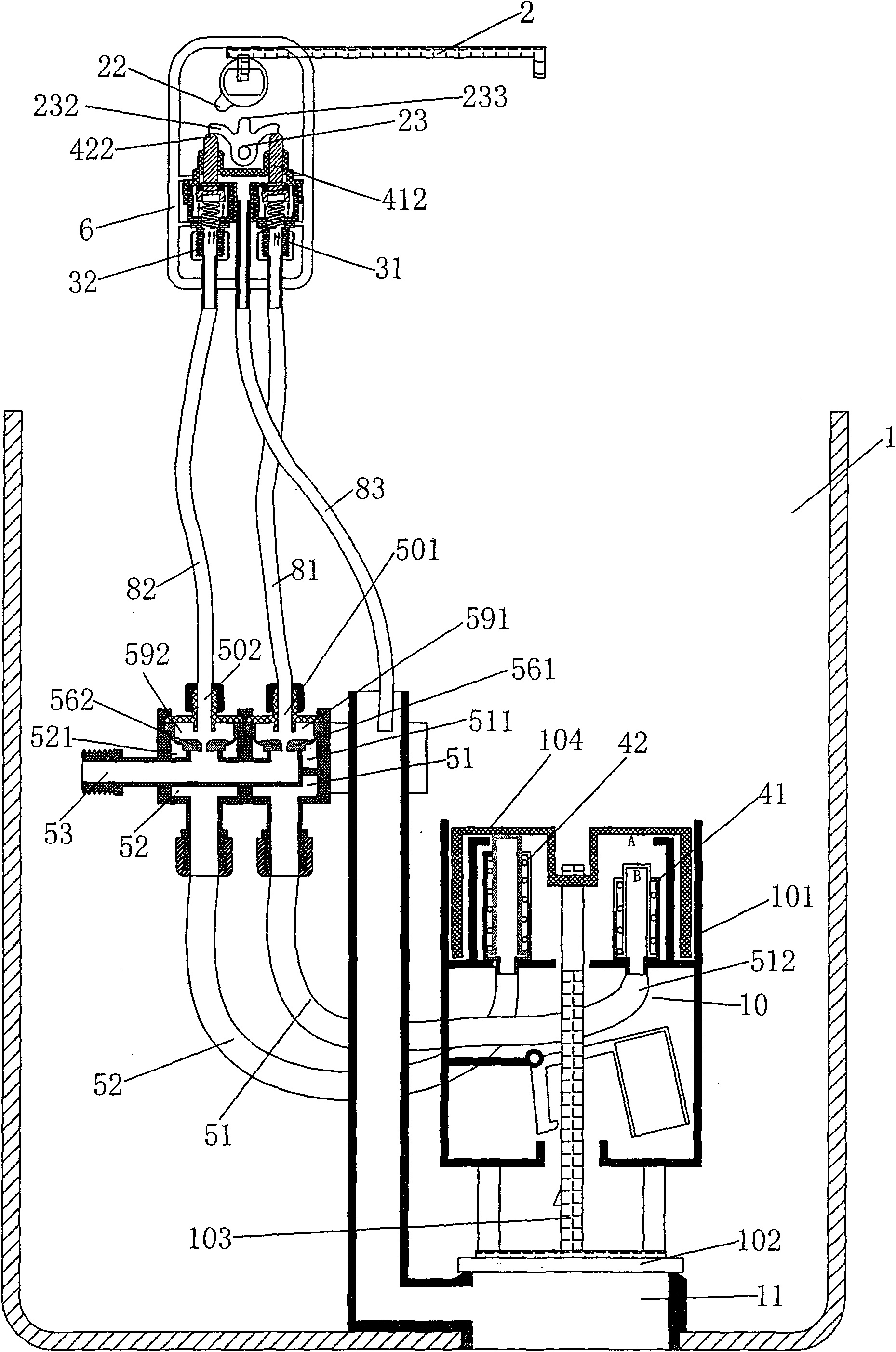

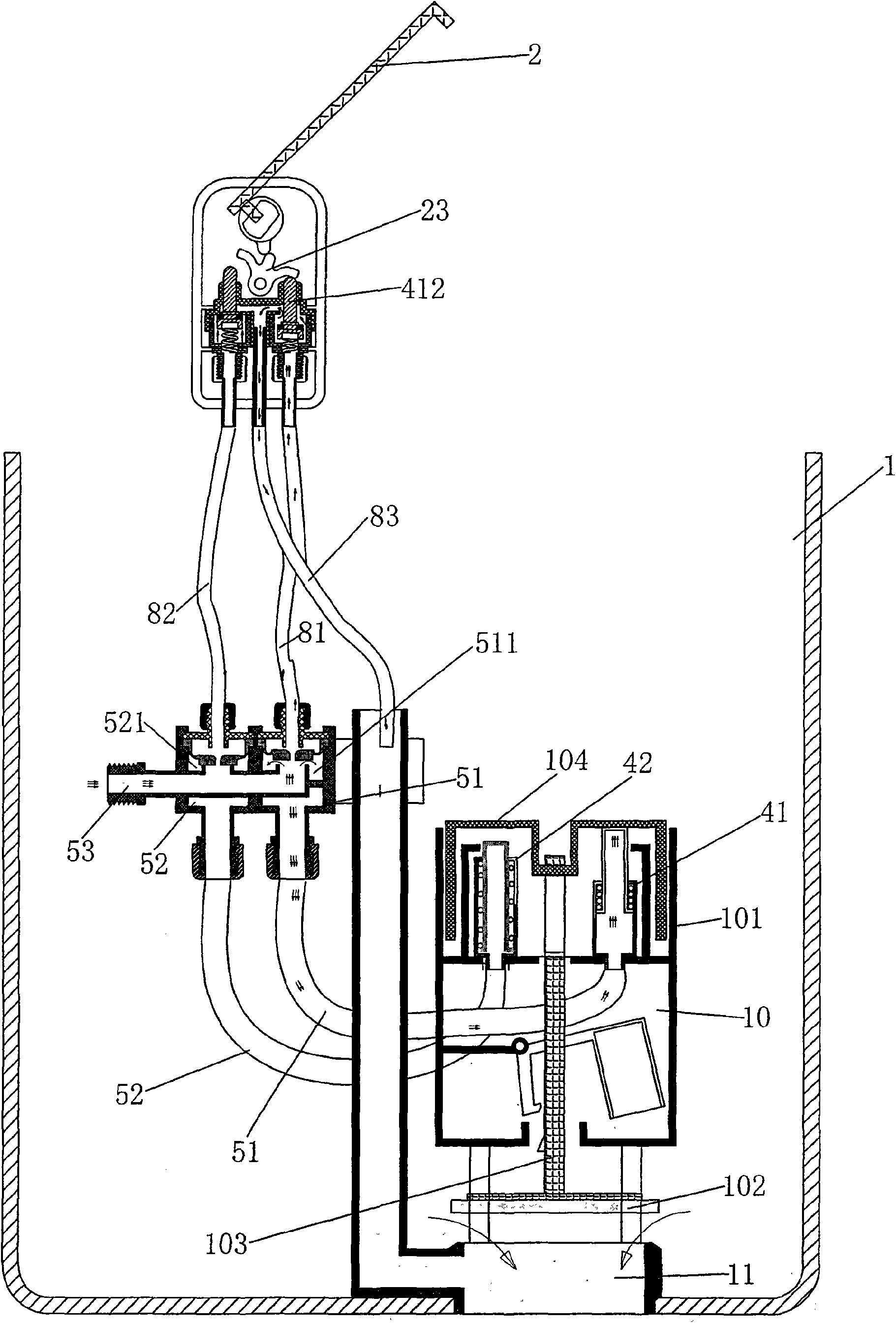

[0033] figure 1 , Figure 5 The shown toilet automatic drainage control device includes a cover plate 2 and a water tank 1, the cover plate 2 is provided with a rotating shaft 21, the water tank is provided with a drain port 11, a drain valve 10, and the drain valve is provided with a valve wall 101, a valve cover sheet 102, The valve cover lifting rod 103, the valve cover 102 is fixedly connected with the valve cover lifting rod 103, and the upper end of the valve cover lifting rod 103 is also connected with a transmission horizontal piece 104; figure 1 , Figure 9 , Figure 10 As shown, a first hydraulic cylinder 41 and a second hydraulic cylinder 42 are also provided in the water tank. A first piston rod 412 can be axially moved in the first hydraulic cylinder 41, and a first piston rod 412 can be installed in the second hydraulic cylinder 42. A second piston rod 422 is installed axially movable, and both the first piston rod and the second piston rod are located below t...

Embodiment 2

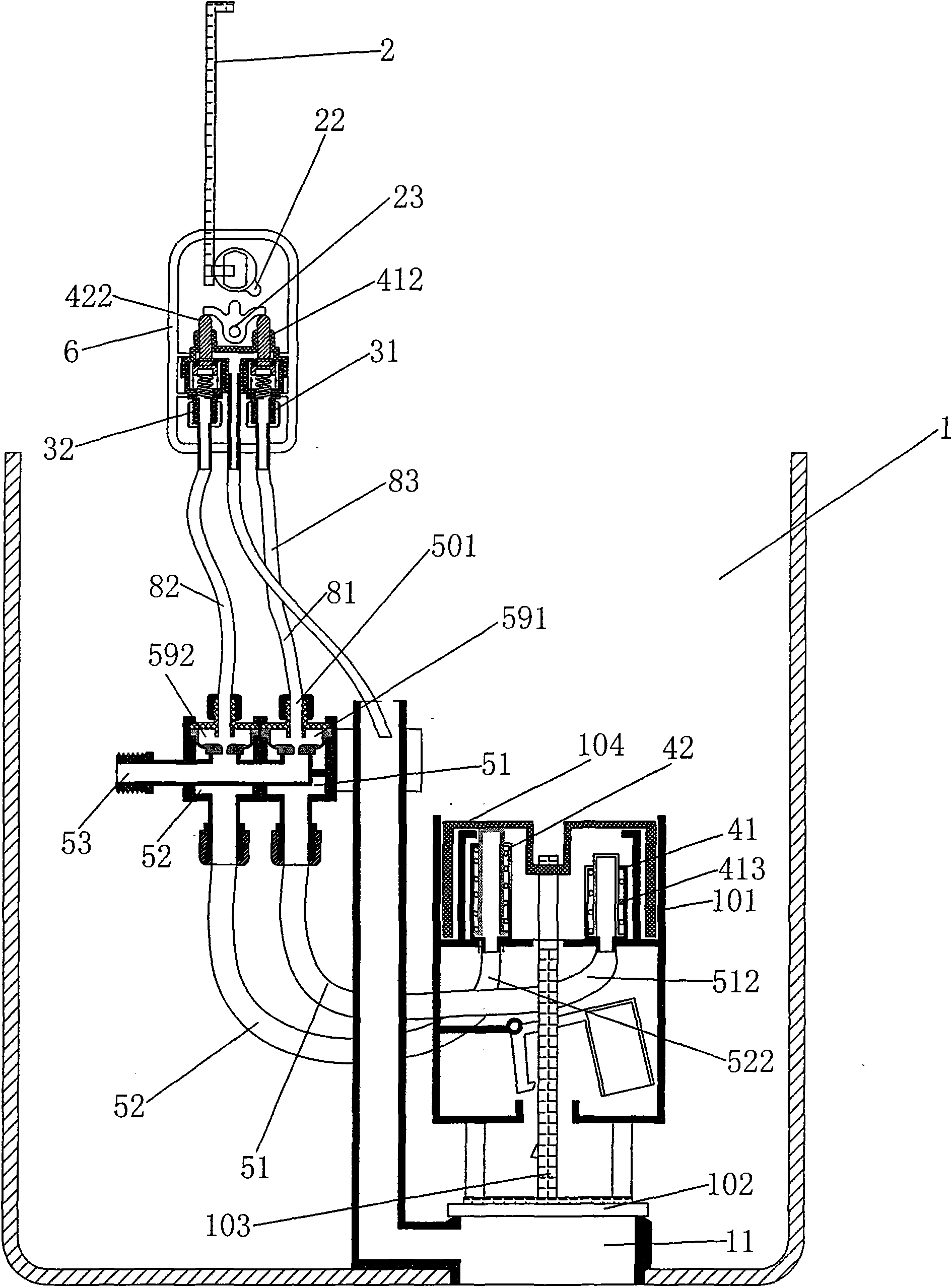

[0050] The structural principle and working process of the second embodiment are basically the same as those of the first embodiment, except that the structural form is slightly changed.

[0051] Figure 12 As shown, in Embodiment 2, the principle of the transmission structure of the cover plate, the first pressure relief valve, and the second pressure relief valve is the same as that of Embodiment 1, but the trident transmission block is in the shape of an inverted T.

[0052] Figure 14 , Figure 15 As shown, the first rubber pad 561 and the second rubber pad 562 in the second embodiment are flat, and the first small channel 571 between the first water pipe 551 and the first pressure chamber 591 is arranged beside the first water pipe 551 On the side, the second small channel 572 between the second water pipe 552 and the second pressure chamber 592 is arranged on the side of the second water pipe 552 . The front end 511 of the first water outlet channel is sleeved in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com