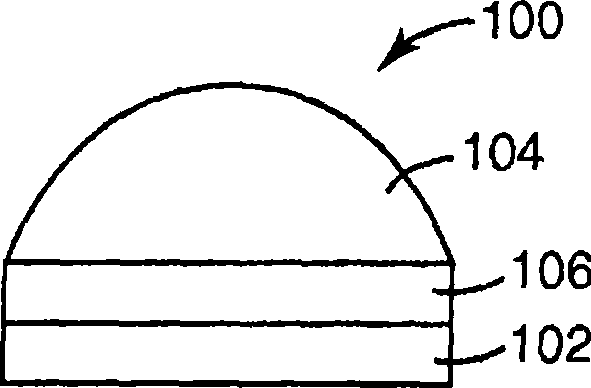

Optical bonding composition for led light source

A technology of LED light source and adhesive layer, applied in the field of LED light source, can solve the problems of affecting the function of the LED light source, limiting the effectiveness, hindering the use of the extractor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0066] Surface modified zirconia nanoparticles were prepared as follows. Mix 100 grams of 23% by weight zirconia sol (25.5% by weight solids in water, solids being zirconia and acetic acid); 100 grams of 1-methoxy-2-propanol; and 5.45 grams of 2-[2- (2-Methoxyethoxy)ethoxy]acetic acid (MEEAA) to obtain a mixture with 1.2 mmoles of MEEAA per gram of zirconia. The mixture was placed on a rotary evaporator to remove solvent. A dry solid was obtained and the solid was further dried in a vacuum oven at 60°C for about 12 hours. The resulting dry powder was dispersed in 229.5 grams of methanol to form a translucent liquid with 12 wt% nanoparticles.

[0067] By vortexing 50 g of poly(phenylsiloxane) (C 6 h 5 SiO 1.5 ) x Glass resin pellets (GR-950 from Techneglas Ltd.) and 115 grams of acetone for 30 minutes until a clear solution was obtained to prepare a silicone solution comprising these two components.

[0068] A mixture was prepared by mixing 10 grams of the nanoparticle sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com