Preparation method for low excitation photochromic MoO3 censphere film

A technology of hollow microspheres and excitation light, which is applied in the direction of color-changing fluorescent materials, chemical instruments and methods, can solve the problems that the preparation method has not been reported, and achieve the improvement of photochromic reaction activity, simple method, and obvious specific surface effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

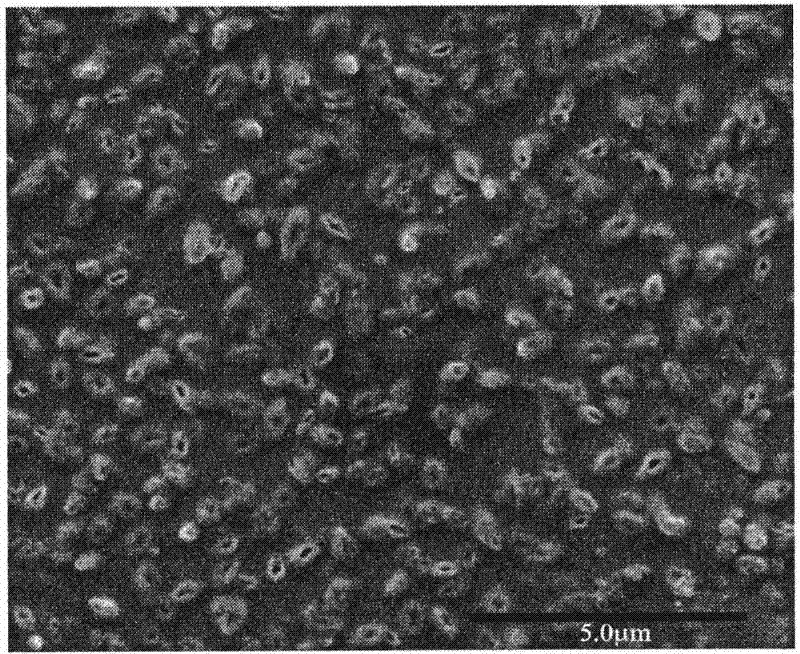

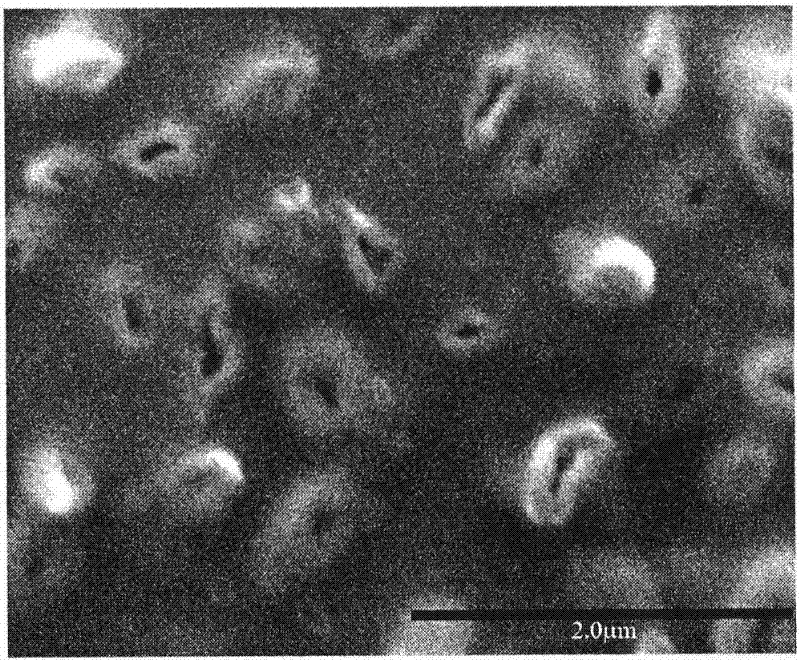

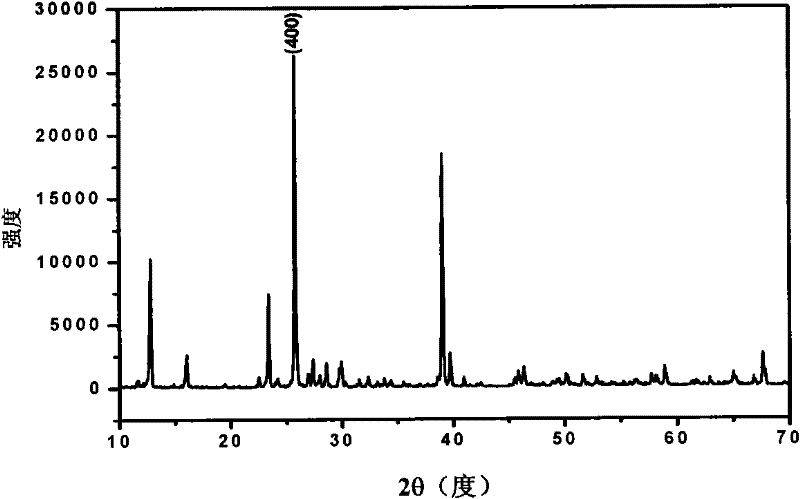

Embodiment 1

[0020] First, add Na 2 MoO 4 Dissolve in double distilled water, make 25mL of 0.2mol / L aqueous solution, fully exchange the solution with cation exchange resin to obtain molybdic acid aqueous solution, add 25mL number average molecular weight drop by drop while stirring at 400r / min It is 2000-5000 polyacrylic acid, then 10mL n-propanol is added dropwise, and then the reaction system is stirred and homogenized for 4h to form a sol, and it is placed in the dark to stand for 24h. The glass substrate is washed with water to remove surface stains, then soaked in acid, then boiled with distilled water, then washed with alcohol and dried with alcohol to make the substrate clean. Then the glass substrate was immersed in the sol, and the glass substrate was coated with a dipping and pulling method at a pulling speed of 20mm / s for 120s, and then the glass substrate was dried at 50°C. Finally, put the coated glass slide in a resistance furnace and heat it to 200℃ for 1h, then heat it to 3...

Embodiment 2

[0026] First, change K 2 MoO 4 Dissolve in double distilled water, make up 25mL of 0.05mol / L aqueous solution, fully exchange the solution with cation exchange resin to obtain molybdic acid aqueous solution, add 20mL number average molecular weight dropwise while stirring at 300r / min Is 2000-5000 polyacrylic acid, and then add 30mL n-propanol dropwise. Then, the reaction system was stirred and homogenized for 5 hours to form a sol. The glass substrate was treated in the same manner as in Example 1 to make it clean, and then the glass substrate was immersed in the sol, and the dipping method was used to extract 23mm / s. The drawing speed is to coat the glass substrate with a coating time of 130s, and then the glass substrate is dried at 70°C. Finally, the coated glass slide is placed in a resistance furnace to first heat up to 180°C for 50 minutes, and then to 650°C at a rate of 12°C / min, hold for 1 hour, and sinter under these conditions to obtain photochromic MoO 3 film. Using...

Embodiment 3

[0028] First, the (NH 4 ) 2 MoO 4 Dissolve in double distilled water, make up 25mL of 2.5mol / L aqueous solution, fully exchange the solution with cation exchange resin to obtain molybdic acid aqueous solution, under stirring at 200r / min, add 12.5mL number average dropwise Polyacrylic acid with a molecular weight of 2000-5000 is then added dropwise to 5 ml of n-propanol. Then, the reaction system was stirred and homogenized for 3.5 hours to form a sol, and it was placed in a dark place to stand for 24 to 48 hours. Treat the glass substrate to make it clean by the same method as in Example 1, and then immerse the glass substrate in the sol, and coat the glass substrate with a dipping and pulling method at a pulling speed of 15mm / s. The immersion time is 110s. , And then dry the glass substrate at 65°C. Finally, the coated glass slide is placed in a resistance furnace and heated to 150°C for 1.5h, then heated to 450°C at a rate of 8°C / min for 1.5h, and sintered under this conditi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com