Nanometer zirconia sol and preparation method thereof

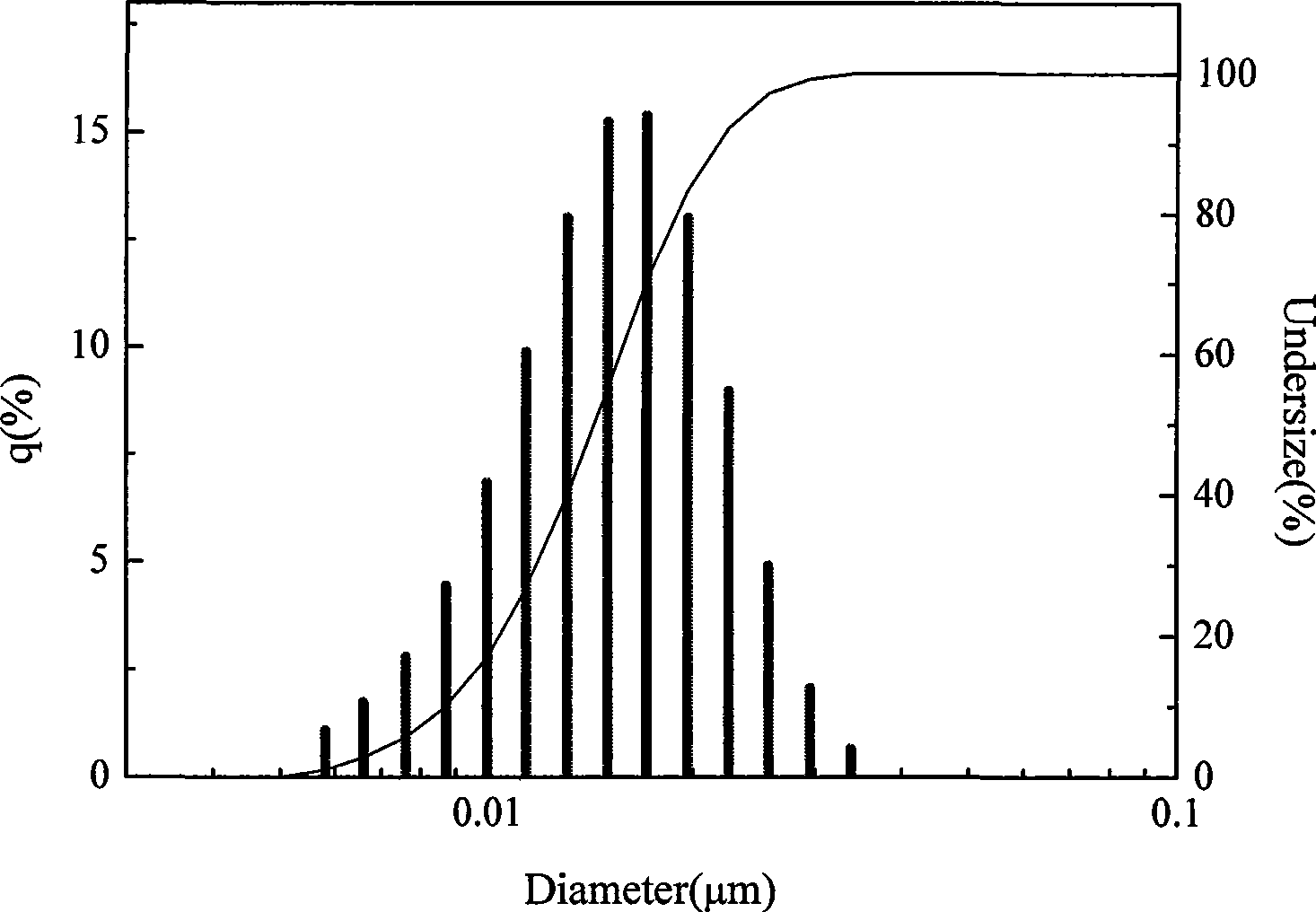

A nano-scale, zirconium-based technology, used in chemical instruments and methods, zirconium compounds, inorganic chemistry, etc., can solve problems such as unsuitable industrial production applications, low zirconia sol content, and complex equipment and equipment, saving labor resources, particle size, etc. The effect of narrow distribution and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A nano-scale zirconium sol and its preparation method: first, under the condition of stirring at 25-35°C, industrial zirconium oxychloride solution with a concentration of 0.1-0.3 mol / L and ammonia water with a concentration of 1.0-1.3 mol / L are mixed Slowly add it dropwise into the ammonium chloride buffer solution with a concentration of 0.1-0.4 mol / L, control the pH value of the mixed solution to 8-10, and continue stirring for 0.5-1 hour to obtain the precursor hydrated zirconium hydroxide precipitate. Then the hydrated zirconium hydroxide precipitate is washed with water and suction filtered for 2 to 4 times to obtain a filter cake; then the filter cake is dispersed in the In water, add nitric acid solution dropwise while stirring to obtain emulsion. Finally, add 0.1-0.4% polyethylene glycol 400 and 0.5-0.8% acetone to the emulsion respectively, and keep stirring for 0.25-0.5 hours; heat in a water bath at 85-90°C for 6-9 hours , to obtain a clear and transparent ...

Embodiment 2

[0019] A nano-scale zirconium sol and its preparation method: first, under the condition of stirring at 25-35°C, an industrial zirconium oxychloride solution with a concentration of 0.3-0.5 mol / L and ammonia water with a concentration of 1.3-1.5 mol / L are mixed Slowly add dropwise to the ammonium chloride buffer solution with a concentration of 0.2-0.5 mol / L, control the pH value of the mixed solution to 8-10, and continue stirring for 0.5-1 hour to obtain the precursor hydrated zirconium hydroxide precipitate. Then the hydrated zirconium hydroxide precipitate is washed with water for 2 to 4 times and suction filtered to obtain a filter cake; then the filter cake is dispersed in the In water, add nitric acid solution dropwise while stirring to obtain emulsion. Finally, add 0.2-0.5% polyethylene glycol 400 and 0.8-1.0% acetone to the emulsion respectively, and keep stirring for 0.25-0.5 hours; heat in a water bath at 85-90°C for 7-10 hours , to obtain a clear and transparent n...

Embodiment 3

[0021] A nano-scale zirconium sol and its preparation method: first, under the condition of stirring at 25-35°C, an industrial zirconium oxychloride solution with a concentration of 0.5-0.7 mol / L and ammonia water with a concentration of 1.5-1.7 mol / L are mixed Slowly add it dropwise into the ammonium chloride buffer solution with a concentration of 0.3-0.6 mol / L, control the pH value of the mixed solution to 8-10, and continue stirring for 0.5-1 hour to obtain the precursor hydrated zirconium hydroxide precipitate. Then the hydrated zirconium hydroxide precipitate is washed with water and suction filtered for 2 to 4 times to obtain a filter cake; then the filter cake is dispersed in the In water, add nitric acid solution dropwise while stirring to obtain emulsion. Finally, add 0.3-0.6% acetic acid and 1.0-1.2% acetone to the emulsion respectively, and keep stirring for 0.25-0.5 hours; heat in a water bath at 85-90°C for 8-11 hours to obtain clear Transparent nano-sized zirco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com