Automatic buffer device of automobile clutch

A buffer device and clutch technology, applied in the field of automobile transmission, can solve problems such as uneven start, personnel and mechanical damage, and poor follow-up performance, and achieve the effects of solving poor follow-up performance, improving safety performance, and reducing the driver's difficulty in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

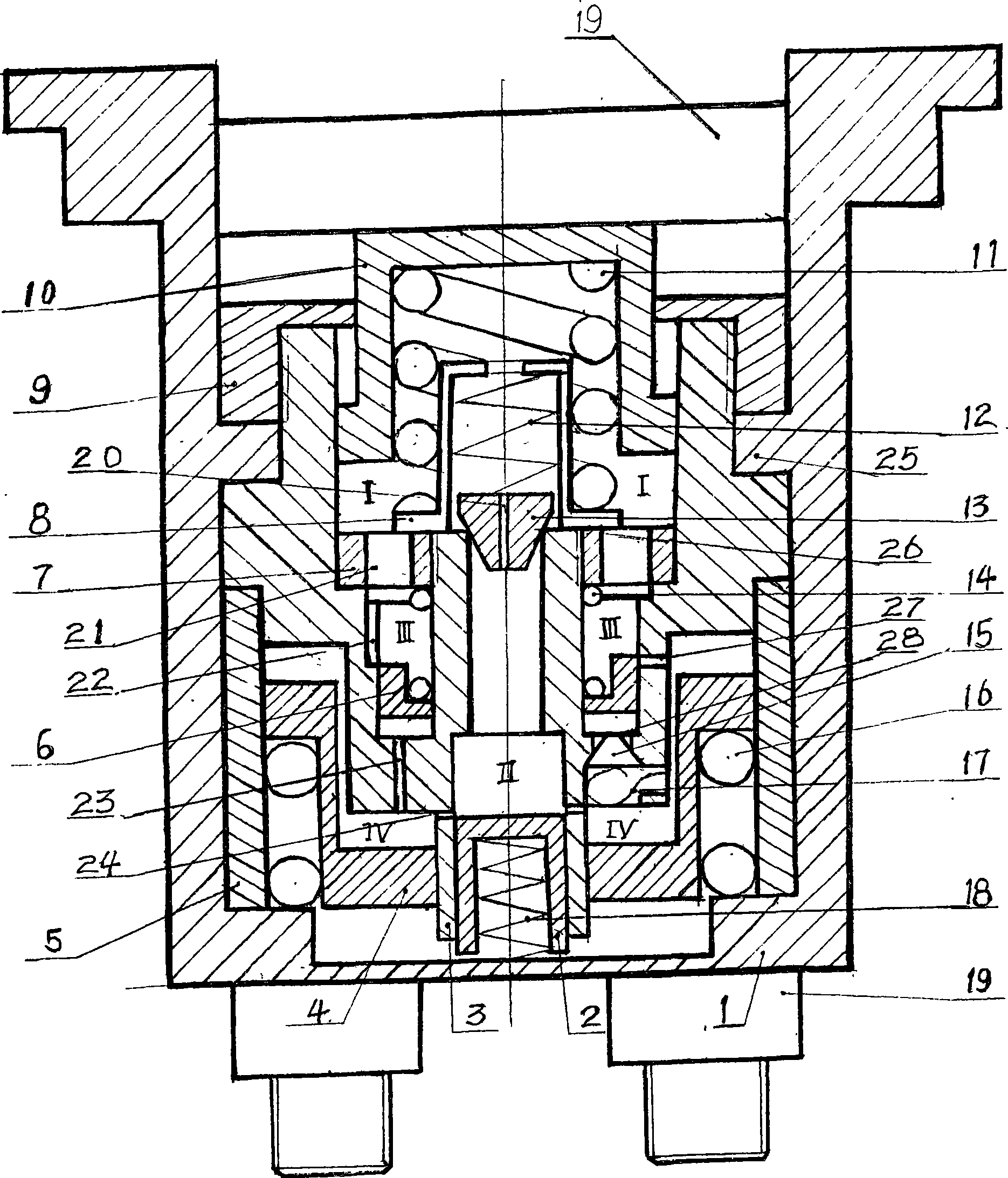

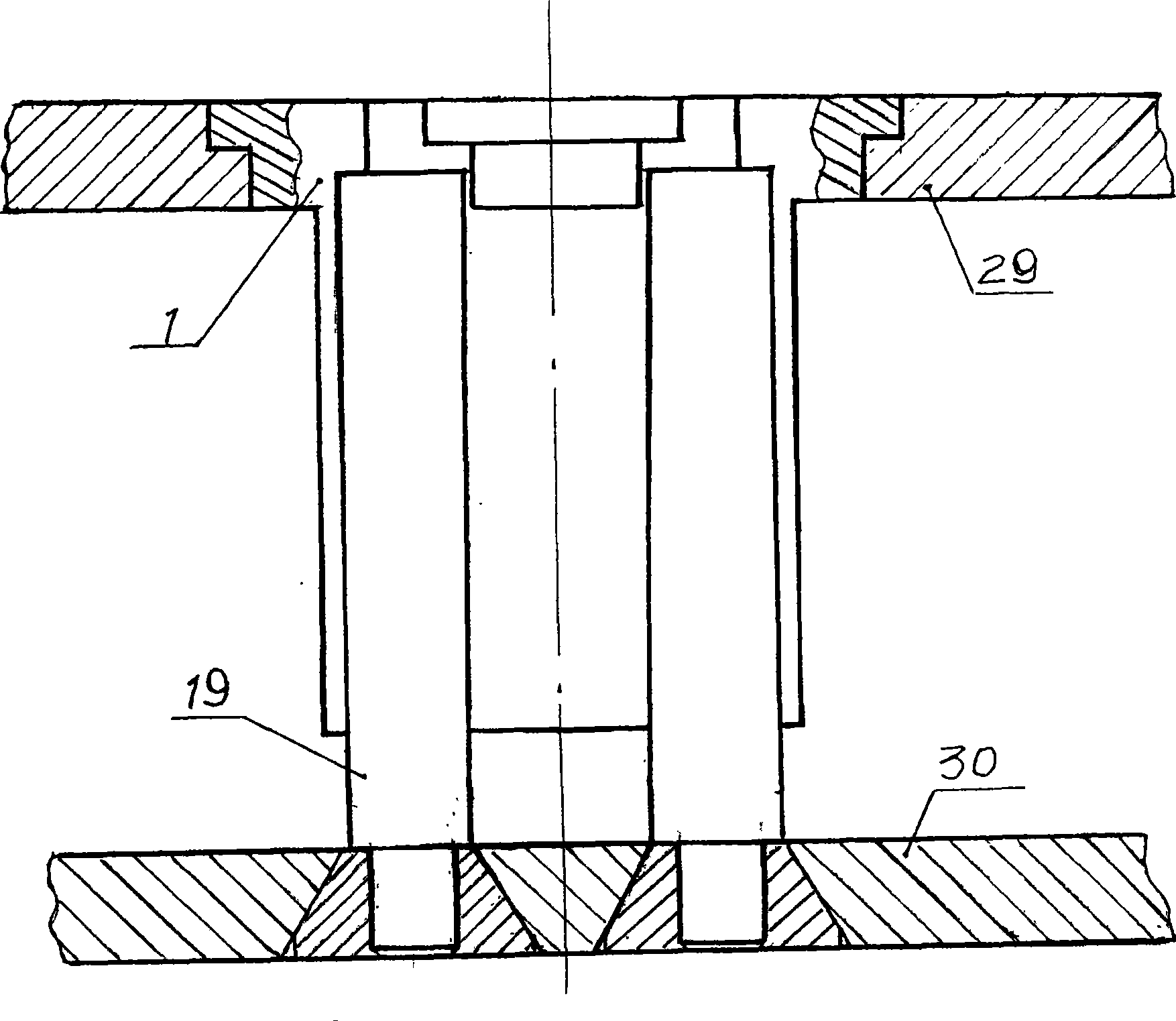

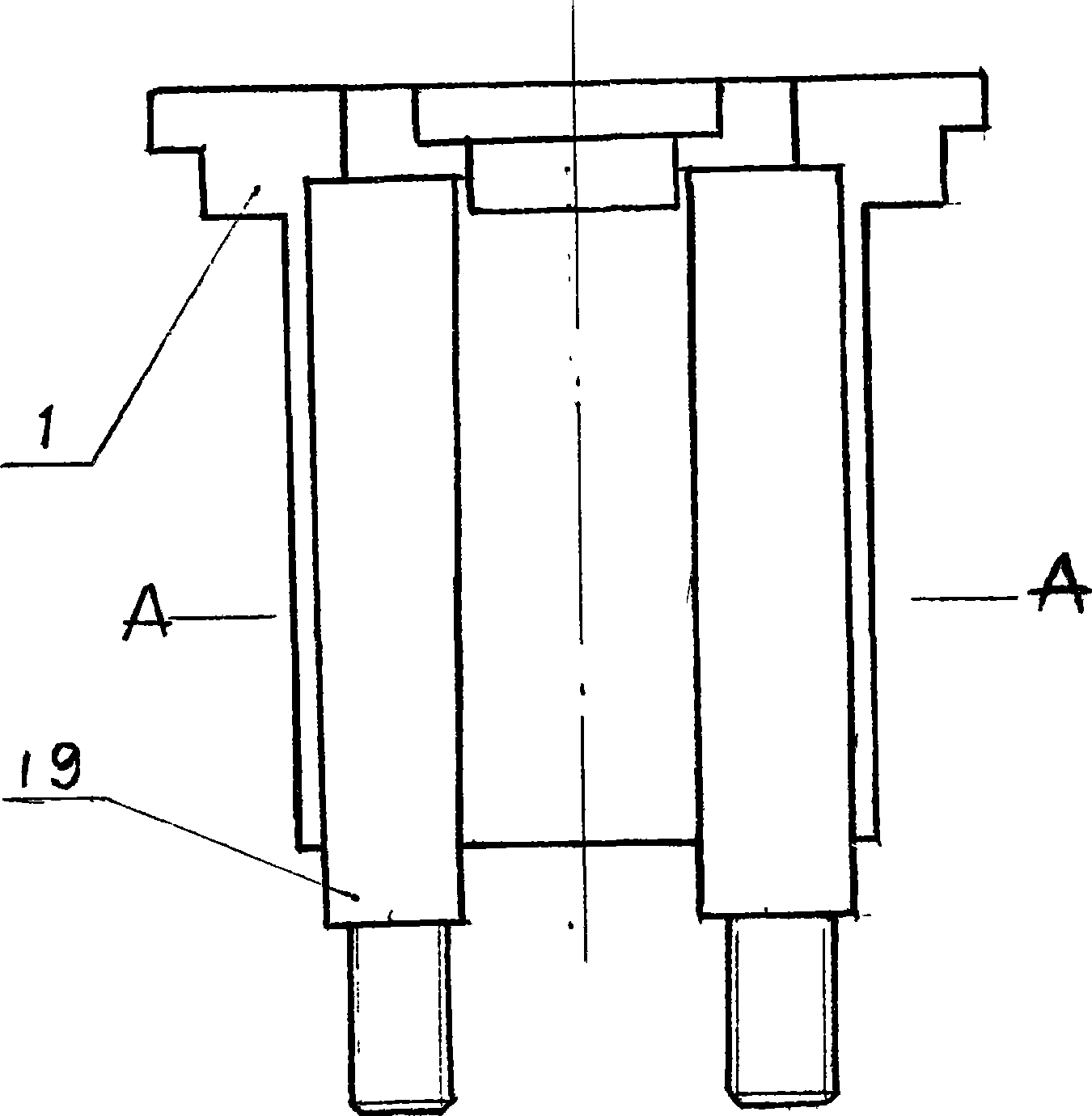

[0011] combine figure 1 and Figure 5 Described as follows, the automatic buffer device of the automobile clutch of the present invention is installed between the clutch cover and the pressure plate. The pressure of the pressure bowl 19 on the upper piston 10 is canceled, and the upper piston 10 pops up under the action of the upper plug spring 11, so that a negative pressure of about 1 kg is generated in the No. I oil cylinder, and the valve 26 is under this negative pressure and the lower positive pressure. The large valve block 13 overcomes the pressure of the large valve spring 12 and moves upward, and the bottom piston 2 in the No. II oil cylinder moves upward under the action of the above-mentioned negative pressure and the bottom plug spring 18 until it stops at the upper limit position, thereby pushing The upper piston 10 moves upwards. At this time, the negative pressure in the No. I oil cylinder still exists. Because the No. I oil cylinder communicates with the No. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com