Bipolar driving linear motor

A linear motor and pole drive technology, applied in the direction of synchronous machines, electrical components, electromechanical devices, etc., can solve the problems of inability to generate an air gap magnetic field at both ends of the winding, difficult processing, etc., achieve good heat dissipation conditions, high magnetic field utilization, and improve The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

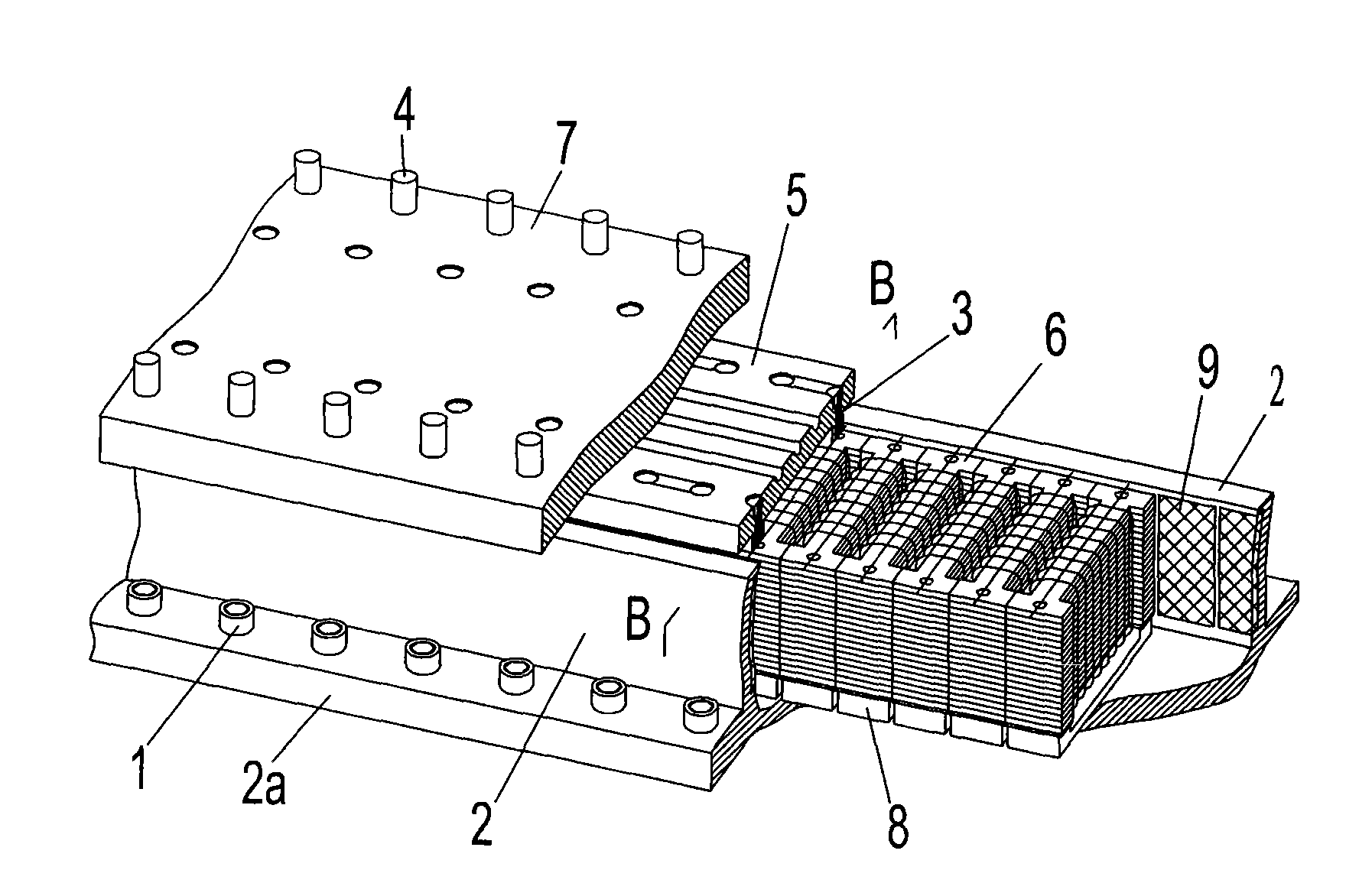

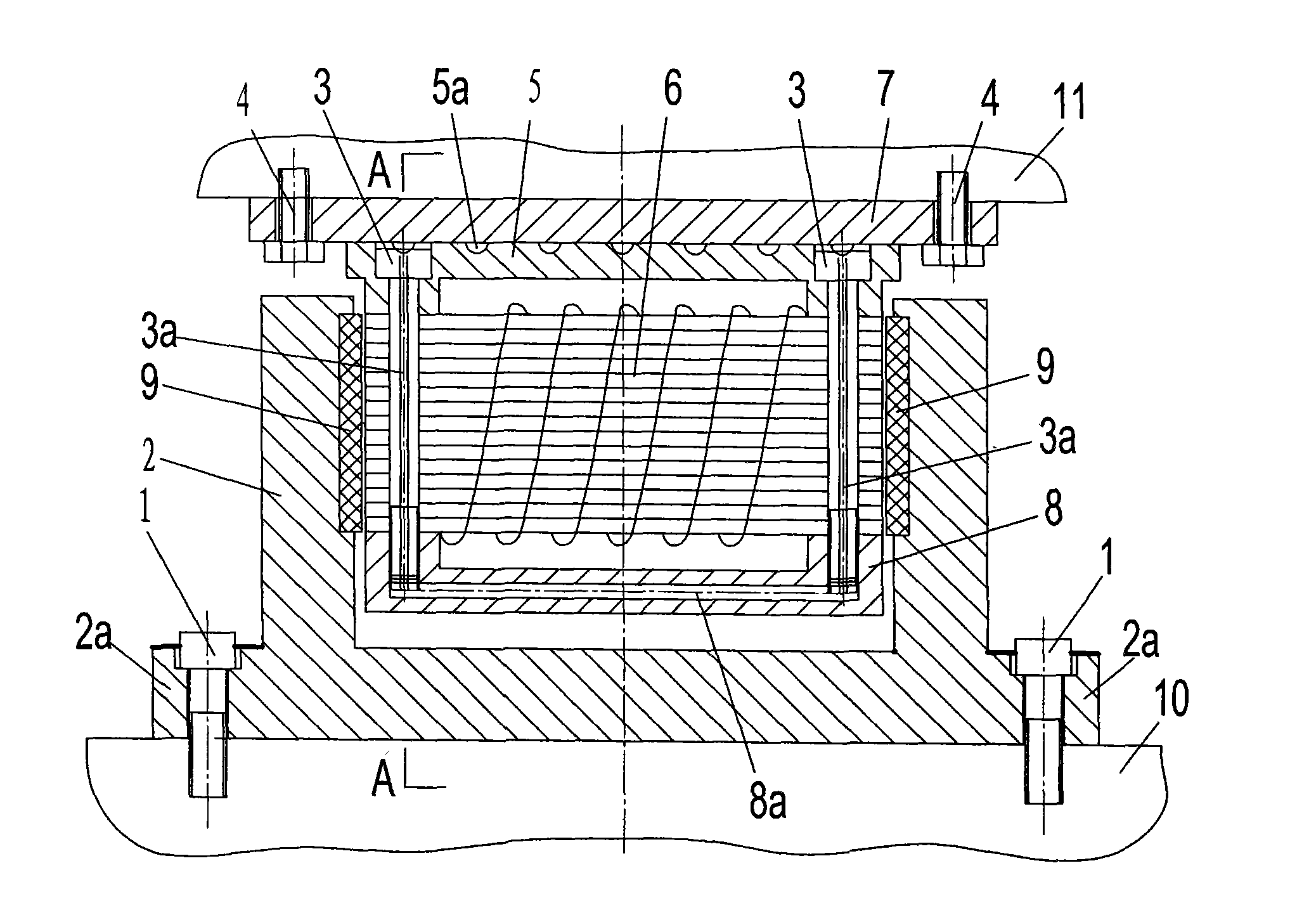

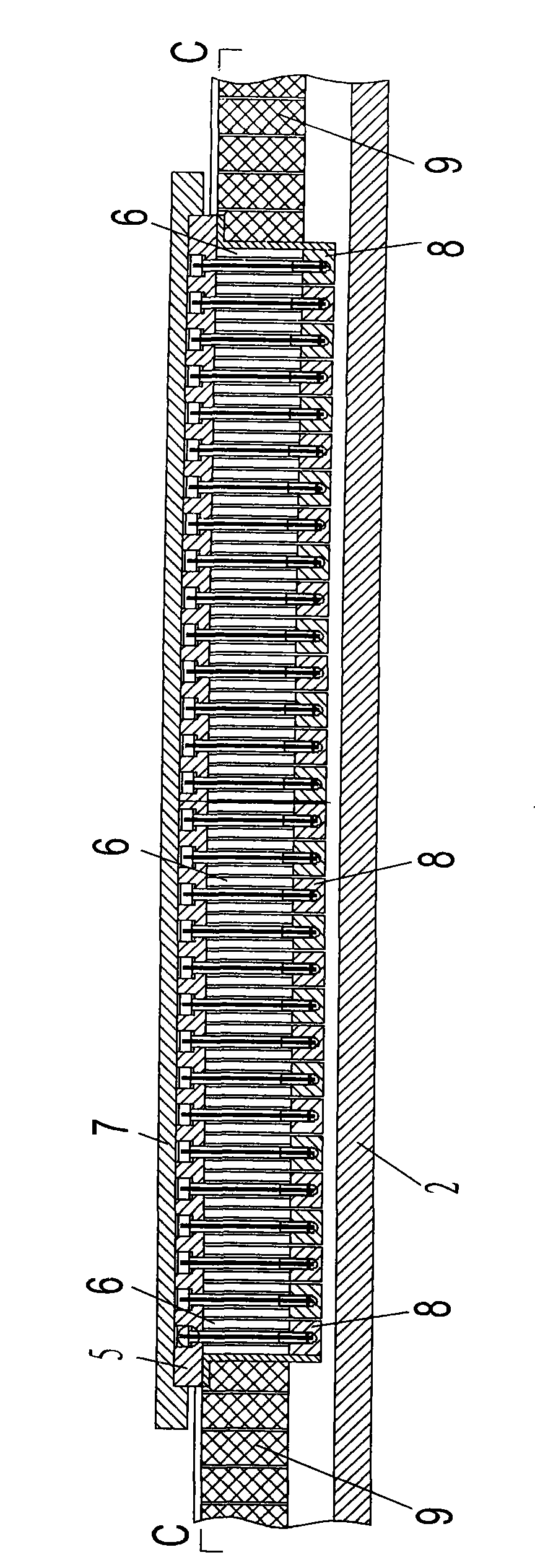

[0023] figure 1 , 2 The main structure of a bipolar driven linear motor is shown. The secondary part of the linear motor is a U-shaped trough-shaped part 2 installed on the supporting part 10, and permanent magnet materials 9 are pasted on the inside of both sides of the U-shaped trough-shaped part 2, and the primary part is installed on the opposite secondary part. The part of the iron core block 6 with the winding coil on the part 11 that moves linearly, the iron core block 6 is located between the permanent magnet materials 9 on both sides of the U-shaped groove part 2, and the part 11 that can move along the line Move along the U-shaped groove. The lower part of each iron core block 6 is provided with an iron core block pressing plate 8 , and the upper part is provided with a cooling plate 5 , and then they are fastened together by connecting bolts 3 . On the upper plane of the cooling plate 5 is provided a cooling groove 5 a closed by the first connecting plate 7 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com