Seafloor cold-water-pipe water taking system for ocean thermal energy conversion power plants

A technology for cold water pipes and power plants, which is applied in the field of subsea cold water pipe water intake systems, can solve the problems of difficult manufacturing and high manufacturing costs, and achieve the effects of strong structural strength and less damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

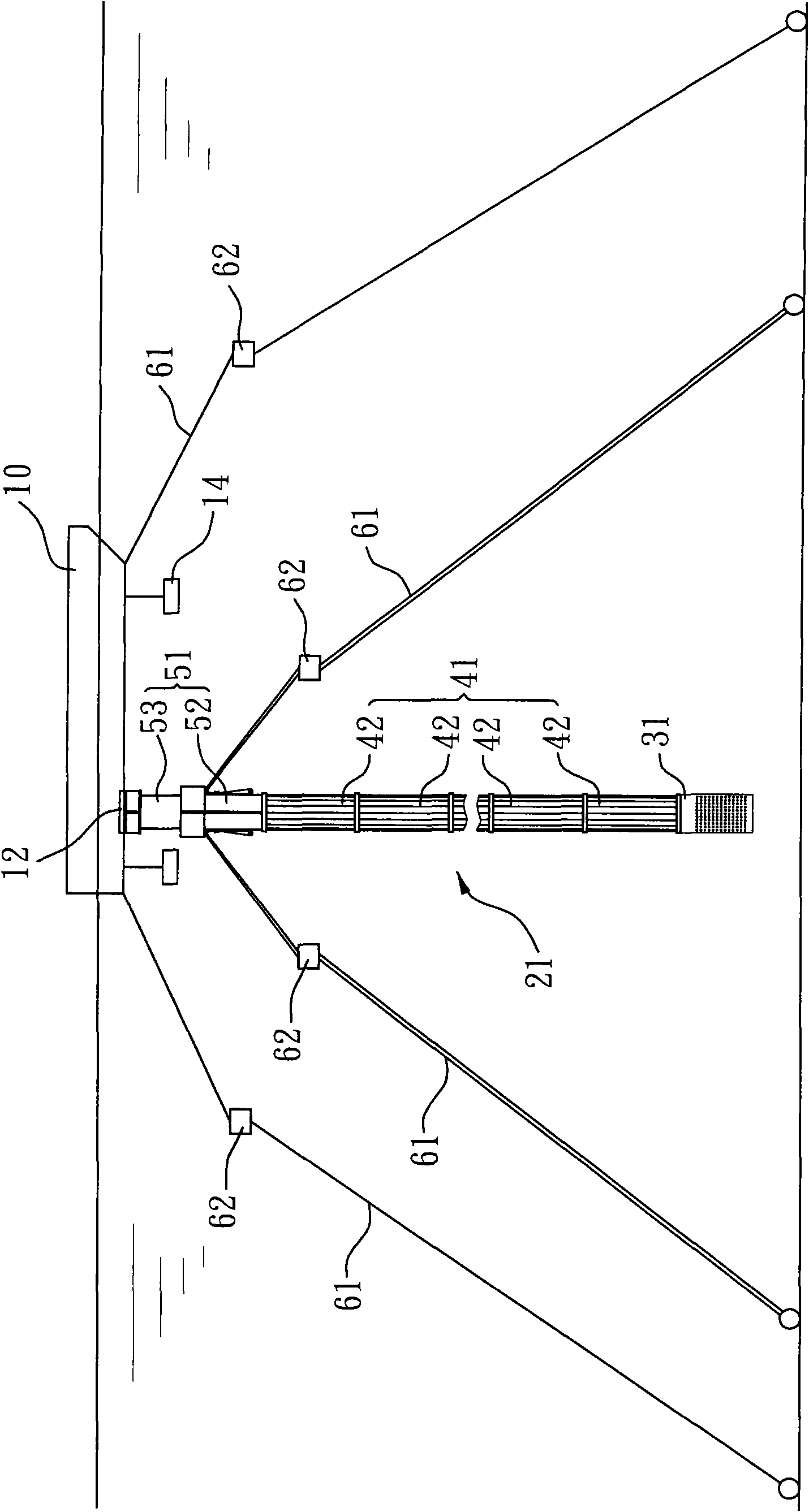

[0029] First see figure 1 , The present invention provides a submarine cold water pipe water intake system for a marine thermoelectric power plant, which is provided with a cold water inlet 12 on a power generation ship 10, and a pumping device is provided at the cold water inlet 12 (not shown in the figure) Show), a cold water pipe 21, one end of which is connected with the cold water inlet 12 of the power generating ship 10, and the other end extends into the seabed to draw low-temperature seawater, and the cold water pipe 21 is mainly composed of a water intake head 31. Consists of a water intake pipe 41 and a connecting pipe 51, in which:

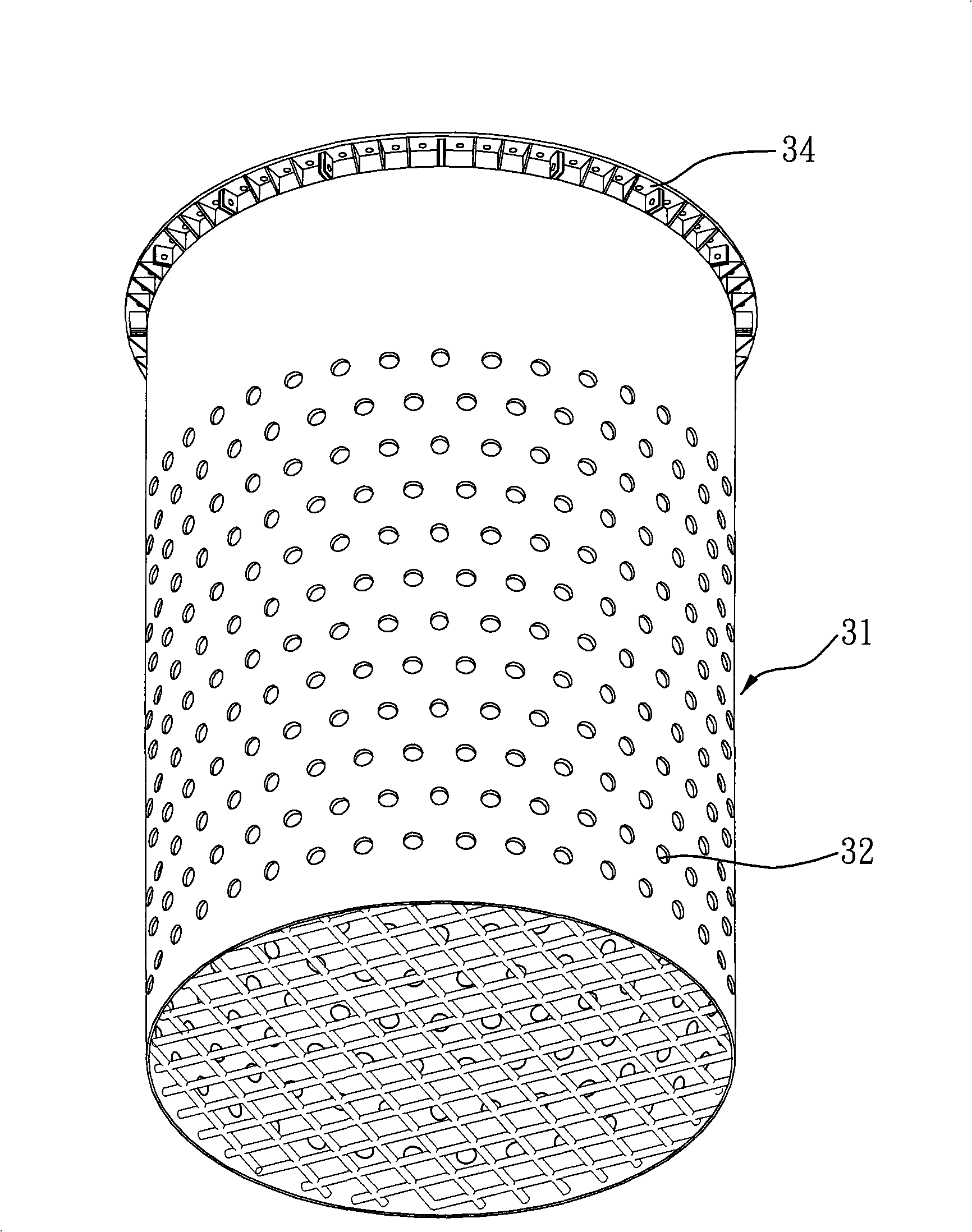

[0030] The water intake head 31, such as figure 2 As shown, the surface is provided with a plurality of filter holes 32 to prevent impurities in the seawater from being sucked by the water intake head 31 when the water intake head 31 performs the water intake action, and the top of the water intake head 31 expands outward to form a Fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com