Common rail electronic control jet apparatus

An injector and common rail technology, which is applied in fuel injection devices, special fuel injection devices, fuel injection devices with wear-reducing measures, etc., can solve the problems of multiple control links, limited electromagnetic force of electromagnets, and high manufacturing costs. Achieve the effect of high energy utilization rate, less control links and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

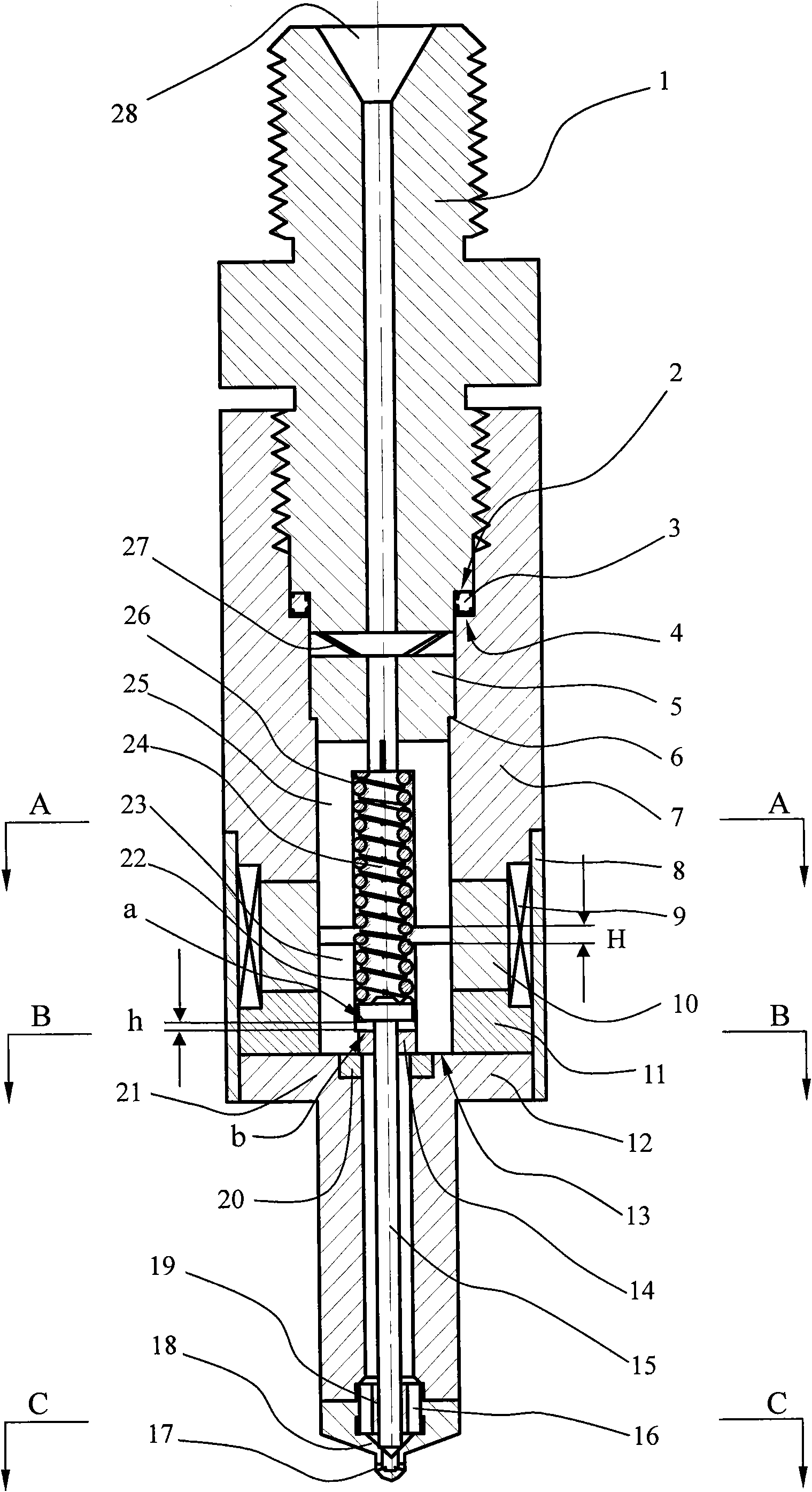

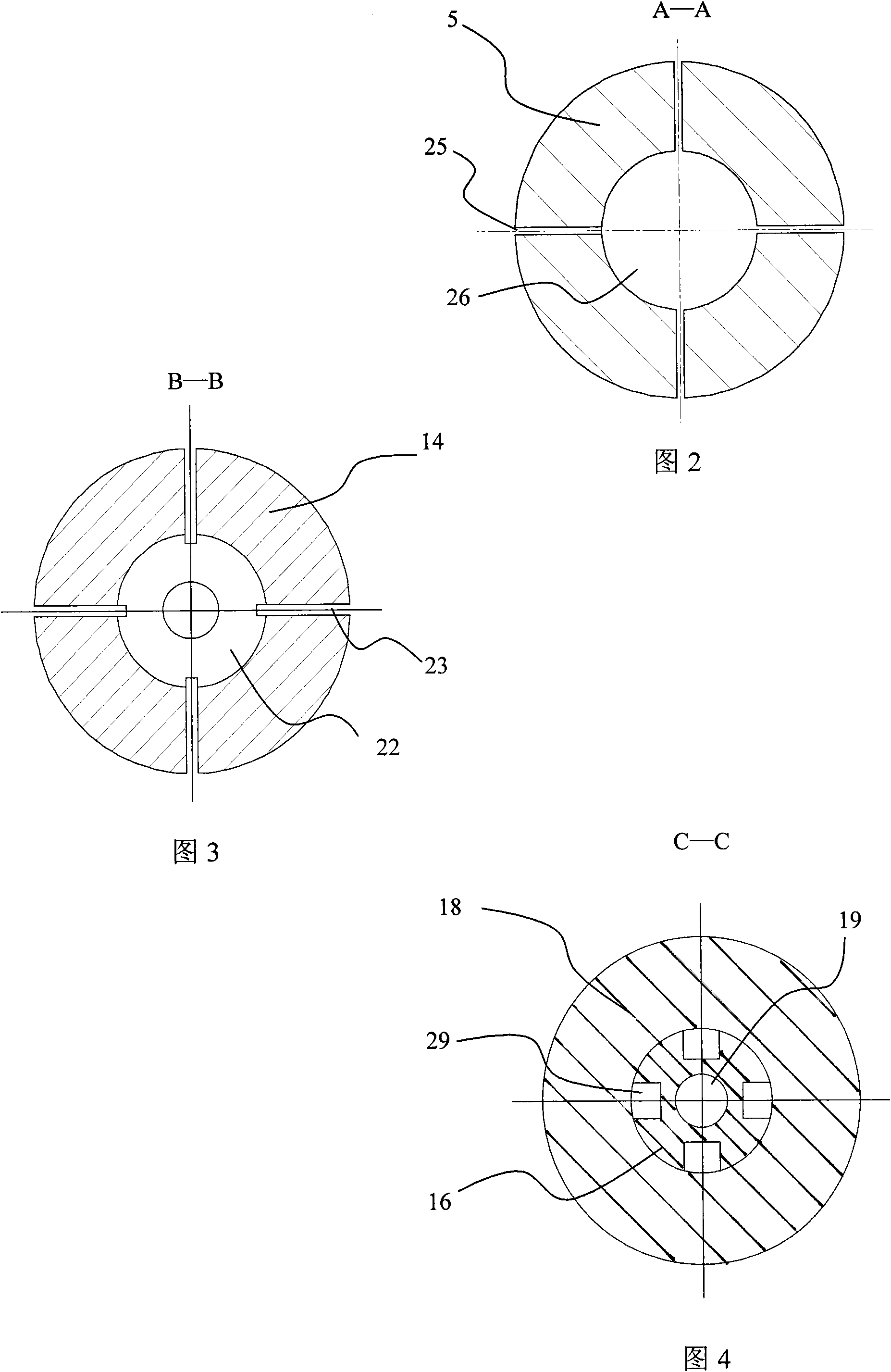

[0021] The structure and principle of the common rail electronically controlled injector will be described in detail below in conjunction with the attached drawings:

[0022] Such as figure 1 As shown, the common rail electronically controlled injector includes: an oil inlet joint 1, an oil inlet 28 located at the outer end of the oil inlet joint 1, an electromagnet device, a nozzle body 12, a needle valve 15, a valve seat 18 and an injection hole 17. Described electromagnet device comprises a static iron core 5, a moving iron core 14 and a coil 9, the working gap H between the static iron core 5 and the moving iron core 14,

[0023] The moving iron core 14 and the needle valve 15 are flexibly connected in the axial direction. When the electromagnet device is powered off and reset, the axial distance between the moving iron core 14 and the needle valve 15 is h. After the electromagnet device is energized, the moving iron core The iron core 14 approaches the needle valve 15 fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com