Resin composition

A technology of resin composition and plastic resin, which is applied in the field of resin composition and can solve the problems of turbidity and opacity of polylactic acid resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

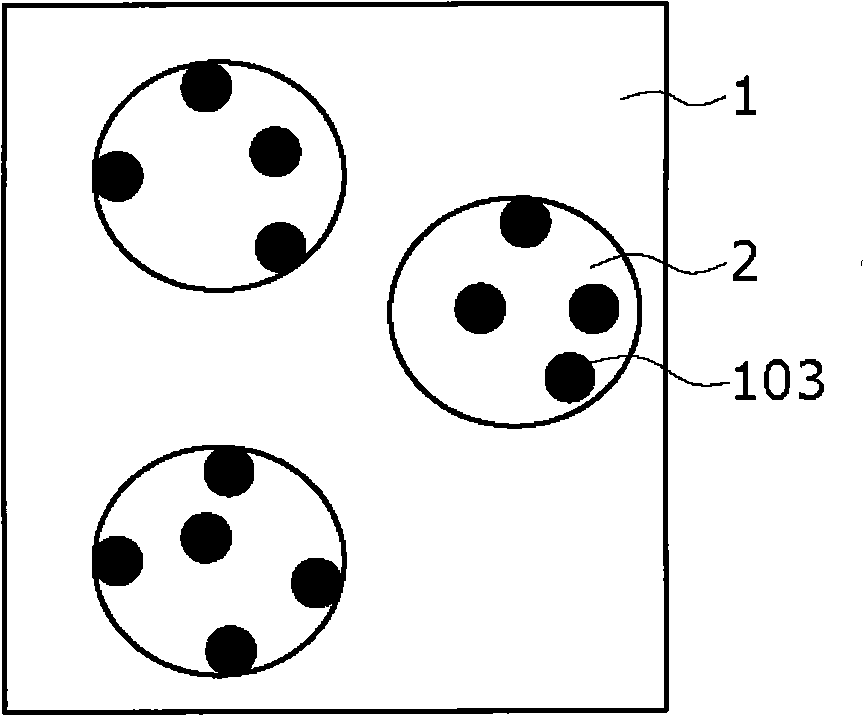

Image

Examples

specific example

[0148] Specific examples thereof are listed below. [2-Hydroxy-4-(methacryloylethoxy)benzophenone]-methyl methacrylate copolymer, [2-hydroxy-4-(methacryloyloxymethoxy)benzophenone Ketone]-methyl methacrylate copolymer, [2-hydroxyl-4-(methacryloyloxyoctyloxy)benzophenone]-methyl methacrylate copolymer, [2-hydroxyl-4-( Methacryloyloxydodecyloxy)benzophenone]-methyl methacrylate copolymer, [2-hydroxy-4-(methacryloyloxybenzyloxy)benzophenone]-methyl Methyl acrylate copolymer, [2,2'-dihydroxy-4-(methacryloxyethoxy)benzophenone]-methyl methacrylate copolymer, [2,2'-dihydroxy- 4-(methacryloyloxymethoxy)benzophenone]-methyl methacrylate copolymer, and [2,2'-dihydroxy-4-(methacryloyloxyoctyloxy)diphenyl ketone]-methyl methacrylate copolymer.

[0149] The above-mentioned UV light absorbers can be used alone or in combination with each other.

[0150] >

[0151] Examples of lubricants are listed below. Petroleum lubricants (such as liquid paraffin), synthetic lubricants (such as hal...

Embodiment 1

[0201]

[0202] The resin composition is composed of polylactic acid resin ("H100" from Mitsui Chemical), polycarbonate resin ("Panlite L-1225LL" from Teijin Kasei) as a heat-resistant resin, and soluble azo Lake pigment PY191 ("PV Fast Yellow HGR" from Clariant, Japan) was prepared.

[0203] A resin composition was prepared by heating and melt mixing polylactic acid resin (60 pbw), polycarbonate resin (40 pbw) and PY191 (3 pbw). Melt mixing was accomplished with a Minimax-Mixruder (from Toyo Seiki) with the nozzle temperature maintained at 230°C.

[0204]

[0205] The crystallization characteristics of the resin composition were analyzed by differential scanning calorimetry (DSC) measuring its crystallization peak temperature. Specifically, DSC was performed by heating a resin composition sample (3-4 mg) placed in an aluminum pan to 230°C and then cooling to 60°C at a rate of 20°C / min. The exothermic peak due to crystallization observed around 100-140°C was considered t...

Embodiment 2

[0215] Except that the nucleating agent of polylactic acid resin is replaced with PR48:4, repeat the procedure of embodiment 1 to prepare resin composition, PR48:4 is soluble azo lake pigment, is manganese salt (from Dai-Nippon Ink and Chemicals "Symuler Red 3037"). The crystallization peak temperature of the resin composition was checked by DSC and observed under an optical microscope.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com