Method for producing carboxymethyl cellulose by using side products of processing yellow gingers with catalysis-solvent method

A technology of carboxymethyl cellulose and by-products, which is applied in the field of production of carboxymethyl cellulose by the catalytic-solvent method of ginger processing by-products, can solve problems such as expensive, unreported, and limited source of raw materials, and achieve production costs low, protect the ecological environment, and realize the effect of resource regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

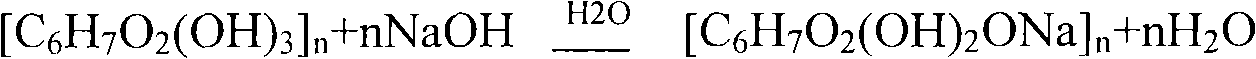

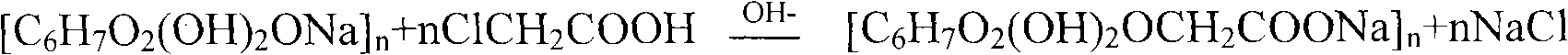

Method used

Image

Examples

Embodiment 1

[0022] Take 8.3g of dry material of catalysis-solvent process turmeric processing by-products, add 100mL of sodium hydroxide solution with a mass concentration of 18%, stir continuously at room temperature for 45min, filter alkali cellulose with a filter press, and reuse the filtered alkali liquor; Add alkali fiber into the reaction bottle, add 120mL of ethanol with a mass concentration of 95% and stir well, then add a solution of 8.9g of monochloroacetic acid and 30mL of ethanol with a mass concentration of 95%, and react at 40°C for 1 hour , heated up to 75°C and reacted for 3 hours; adjusted the pH value to neutral with dilute hydrochloric acid; washed twice with ethanol with a mass concentration of 75%, and washed once with ethanol with a mass concentration of 95%; dried the product, and the waste ethanol solution was distilled back to use; finally the product is dried and pulverized.

Embodiment 2

[0024] Get 1Kg of the catalytic-solvent process yellow ginger processing by-product dry material through sulfuric acid pretreatment, add 12L mass concentration and be 20% sodium hydroxide solution, stir continuously at room temperature for 45min, press filter alkali cellulose with a filter press, and the alkali Liquid reuse; Add alkali fiber into the reaction kettle, add 15L of ethanol with a mass concentration of 95% and stir well, then add 14Kg of monochloroacetic acid and 4L of ethanol with a mass concentration of 95%, and mix it at 40°C React for 1.5 hours, raise the temperature to 75°C and react for 3.5 hours; adjust the pH value to neutral with dilute hydrochloric acid; wash twice with ethanol with a mass concentration of 75%, and wash once with ethanol with a mass concentration of 95%; spin dry the product, waste ethanol solution It is reused by distillation; finally, the product is dried and pulverized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com