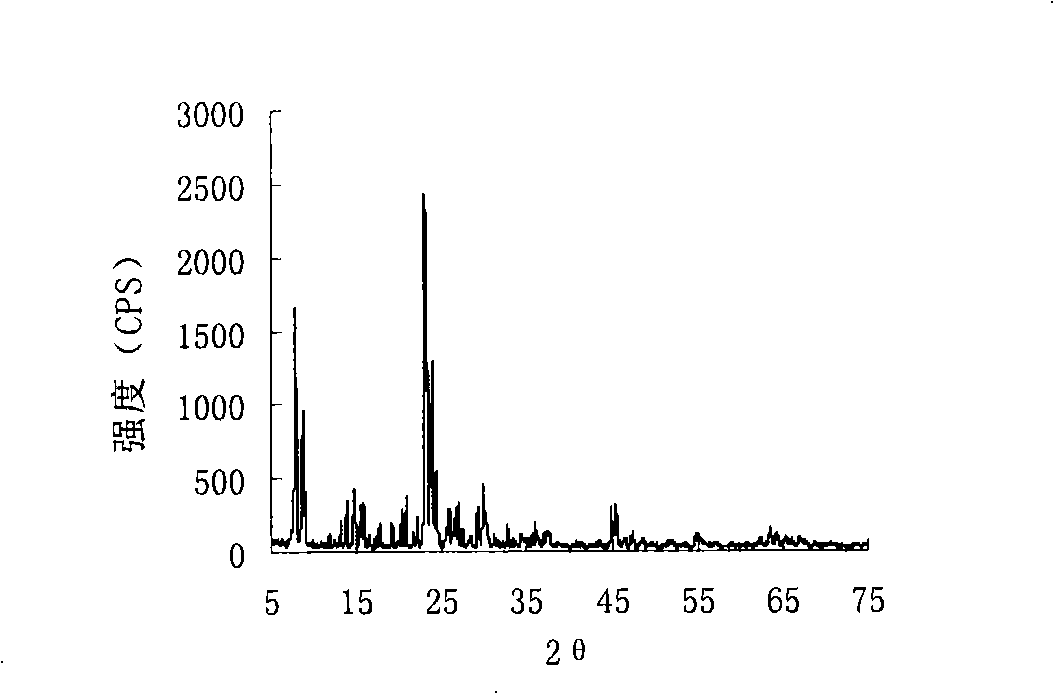

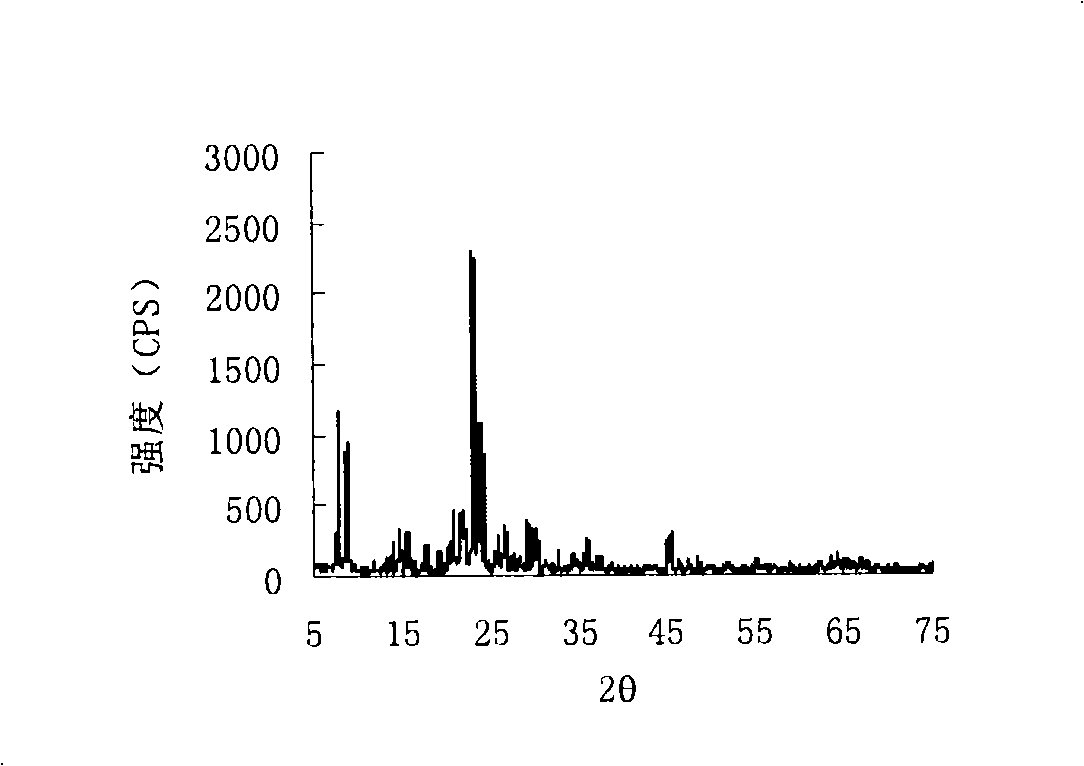

Application of nanometer ZSM-5 molecular sieve in reaction for preparing methanol by dimethyl ether catalysis and hydrolyzation

A technology of ZSM-5 and molecular sieve, which is applied in the direction of molecular sieve catalyst, hydrolysis preparation, physical/chemical process catalyst, etc., which can solve the problems of poor stability and low activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Hydrolysis of Dimethyl Ether to Methanol I

[0049] The nanometer ZSM-5 molecular sieve with a silicon-aluminum ratio of 15:1 is used, and the average particle diameter is 400nm. The molar ratio of dimethyl ether to water vapor is 1:0.5, under the conditions of normal pressure (2.5atm) and reaction temperature of 180°C and space velocity of 1000ml / (gcat h), the methanol content in the product aqueous solution is measured The weight concentration is 26.6%, and there is no by-product in the liquid phase. The calculated dimethyl ether conversion rate is 13.8%, which is close to the equilibrium conversion rate. After 50 hours of reaction, the dimethyl ether conversion rate is 12.5%.

Embodiment 2

[0051] Dimethyl ether hydrolysis to methanol II

[0052] The nanometer ZSM-5 molecular sieve with a silicon-aluminum ratio of 130:1 is used, and the average particle diameter is 100nm. The molar ratio of dimethyl ether to water vapor is 1:5, and the reaction is carried out under the conditions of normal pressure (1.5 atm) and reaction temperature of 220°C and a space velocity of 2000ml / (gcat h). The weight concentration is 13.8%, and there is no by-product in the liquid phase. The conversion rate of dimethyl ether is calculated to be 20.9%, and the conversion rate of dimethyl ether after 500 hours of reaction is 18.6%, which shows that the stability is good.

Embodiment 3

[0054] Hydrolysis of Dimethyl Ether to Methanol III

[0055] The nanometer ZSM-5 molecular sieve with a silicon-aluminum ratio of 60:1 is used, and the average particle diameter is 200nm. The molar ratio of dimethyl ether to water vapor is 1:3, and the reaction is carried out under the conditions of normal pressure (1.0atm) and reaction temperature of 290°C and a space velocity of 20000ml / (gcat h). The weight concentration is 18.1%, the calculated dimethyl ether conversion rate is 23.6%, and the dimethyl ether conversion rate is 14.7% after 50 hours of reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com