LiNH2BH3 synthesis method by taking lithium amide and ammonia borane as raw material

A lithium amide and raw material technology, applied in the direction of borane/diborane hydride, etc., can solve the problems of uneven contact of materials, low product purity, difficult control of reaction temperature, etc., and achieve fast reaction and easy realization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: Preparation of LiNH by liquid reaction method 2 BH 3

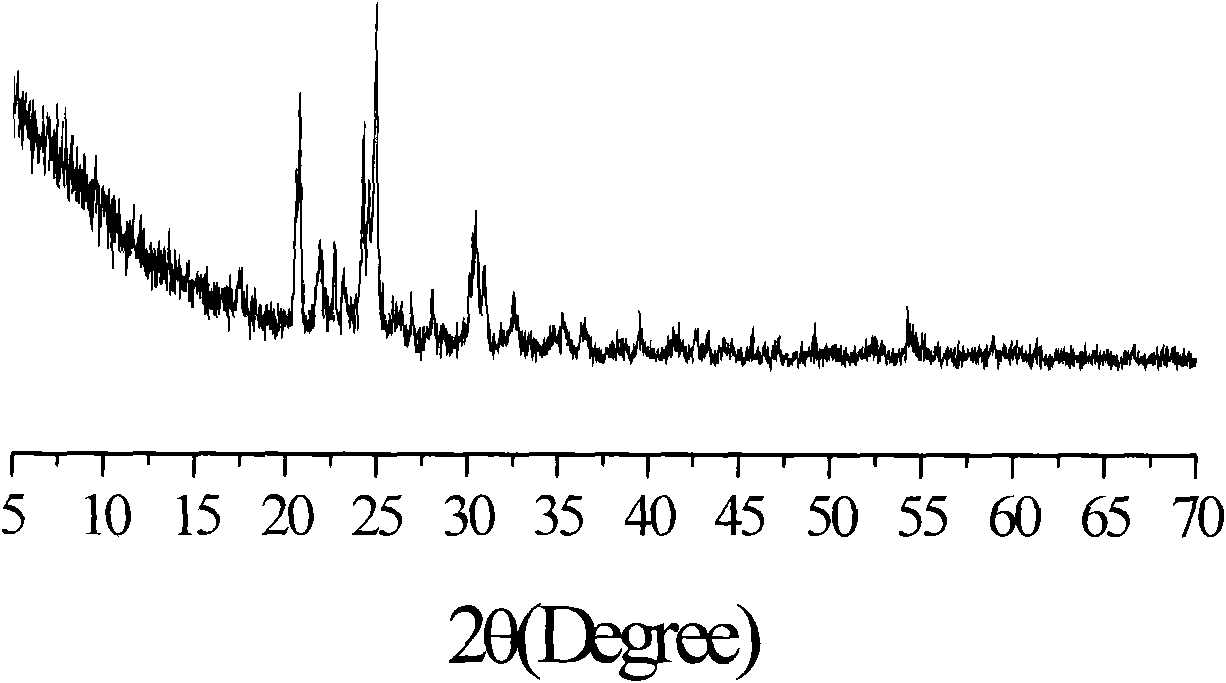

[0021] At room temperature 25°C, in an inert atmosphere, 0.308 g of BH 3 NH 3 Dissolve in 5 mL THF, add to 0.2295 g LiNH 2 , stirred vigorously at room temperature for 3 hours, and vacuum-dried the resulting mixed solution at 40° C. for 12 hours to obtain the final product. figure 1 is the XRD spectrum of the resulting product.

Embodiment 2

[0022] Embodiment 2: Preparation of LiNH by solid state reaction method 2 BH 3

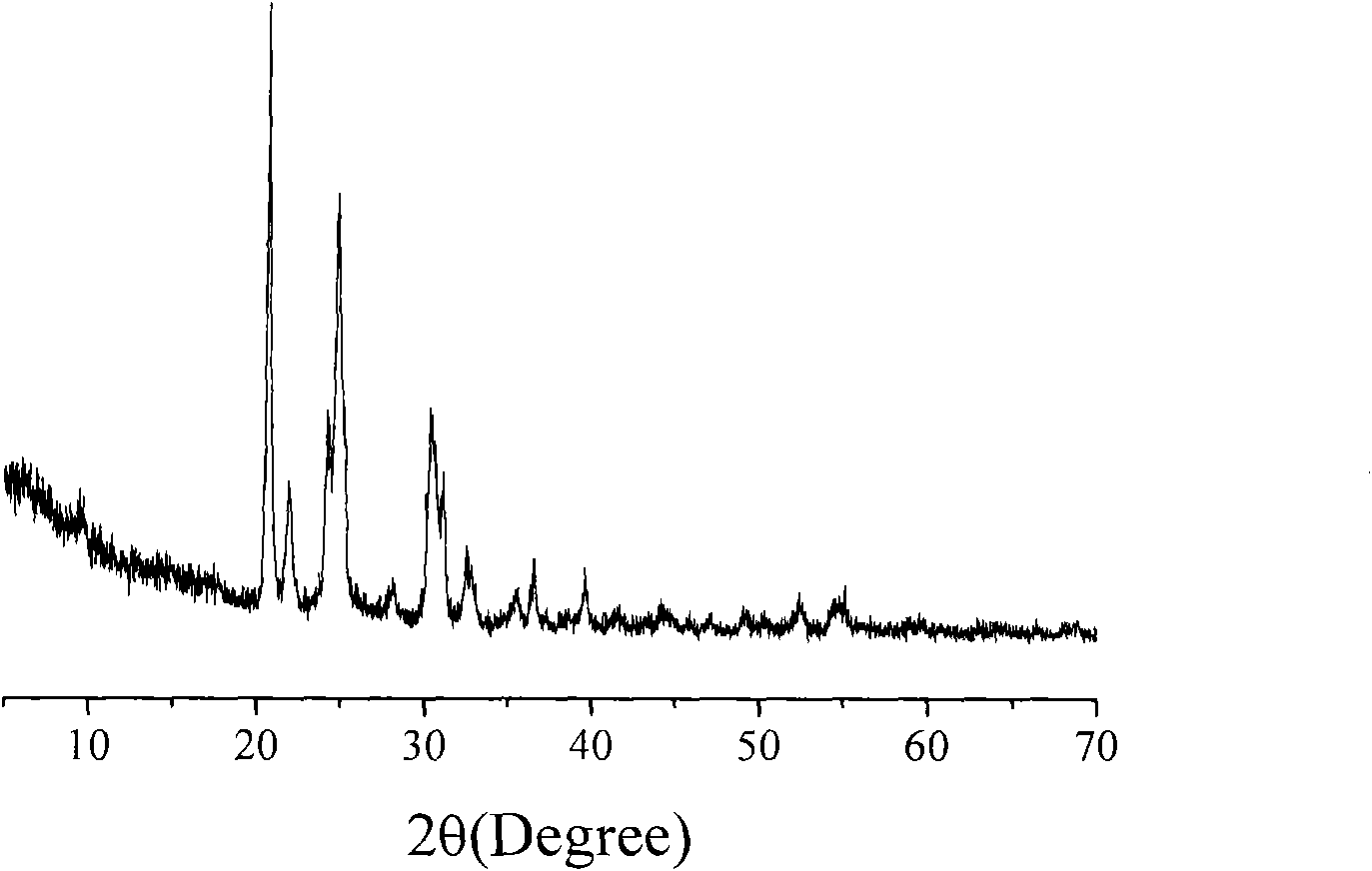

[0023] At room temperature 25°C, 0.308 g of BH 3 NH 3 with 0.2295 g of LiNH 2 Mix and stir under an inert atmosphere, react for 1 minute, and vacuumize the product for 3 hours to remove impurity gas to obtain the product. figure 2 is the XRD spectrum of the resulting product.

Embodiment 3

[0024] Embodiment 3: Preparation of LiNH by liquid reaction method 2 BH 3

[0025] In an inert atmosphere at 10 °C, 0.308 g of BH 3 NH 3 Dissolve in 10 mL THF, add to 0.2295 g LiNH 2 , stirred vigorously at room temperature for 5 hours, and vacuum-dried the resulting mixed solution at 10° C. for 24 hours to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com