Sand belt correcting mechanism of sander

A technology for sanding machines and abrasive belts, which is applied in the direction of abrasive belt grinders, grinding/polishing equipment, grinding machines, etc. It can solve the problems of insufficient rigidity of tension beams and unsatisfactory correction effects, etc., so as to reduce fatigue fractures and reduce fatigue Effects of breaking and shortening lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

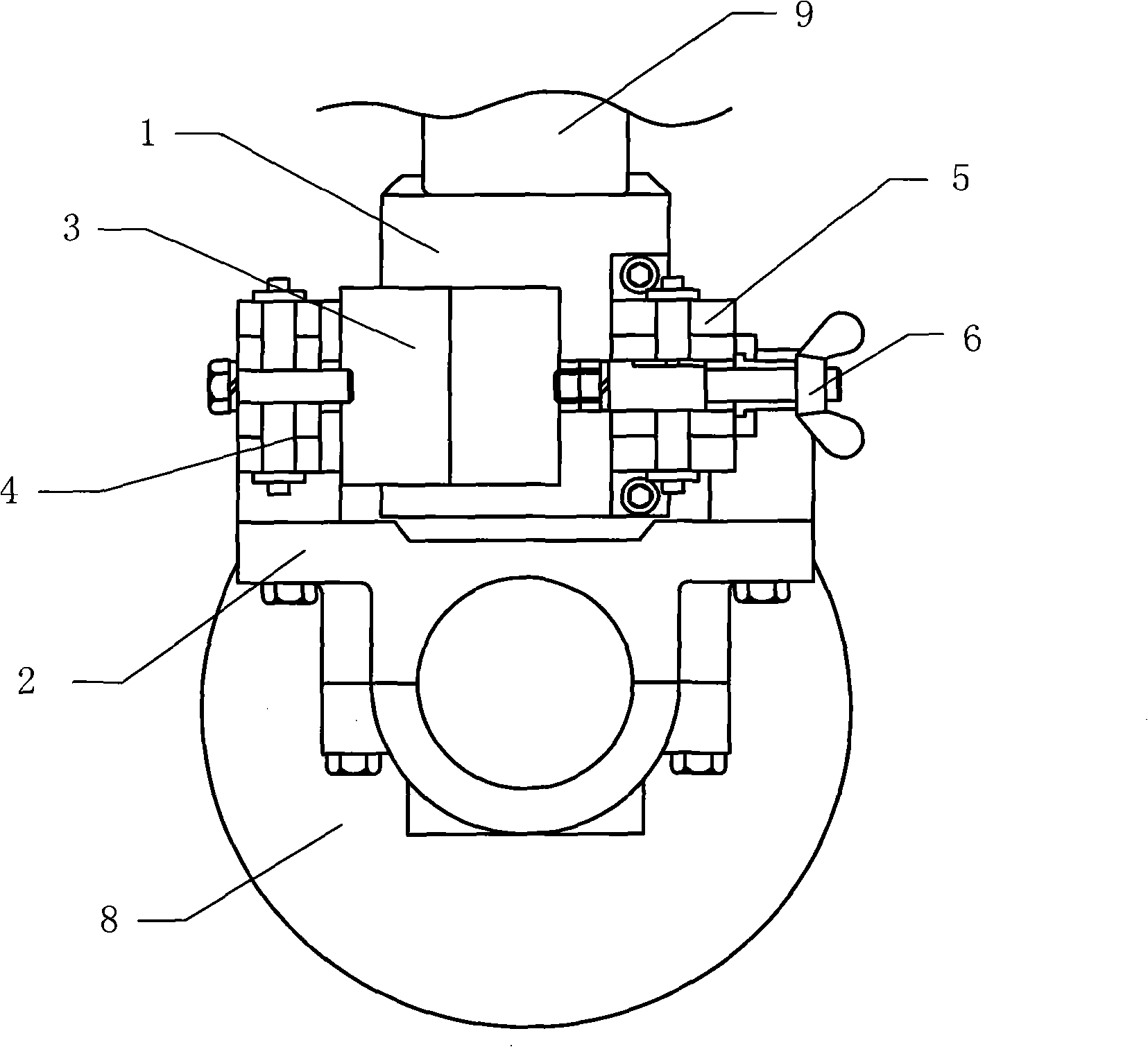

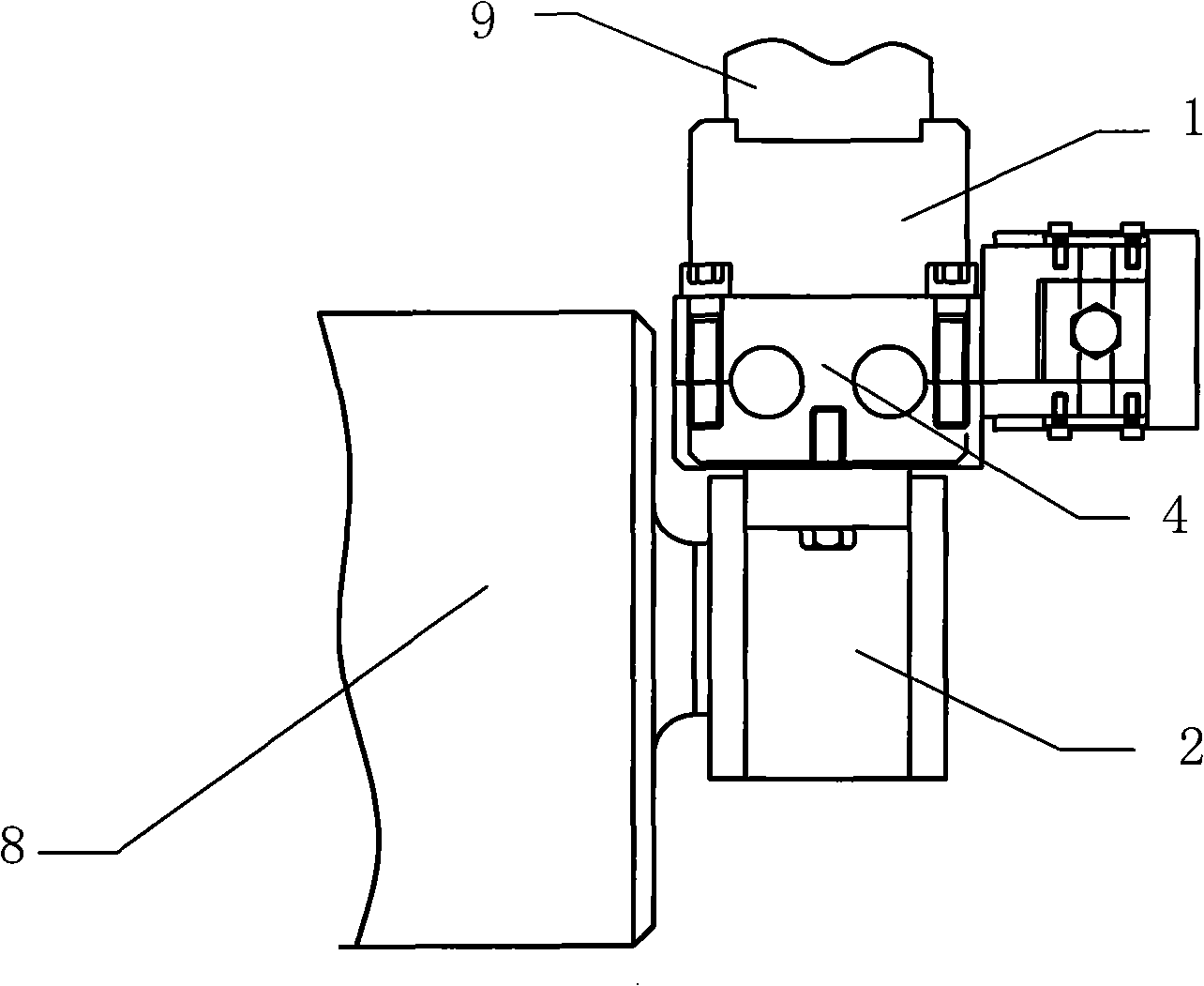

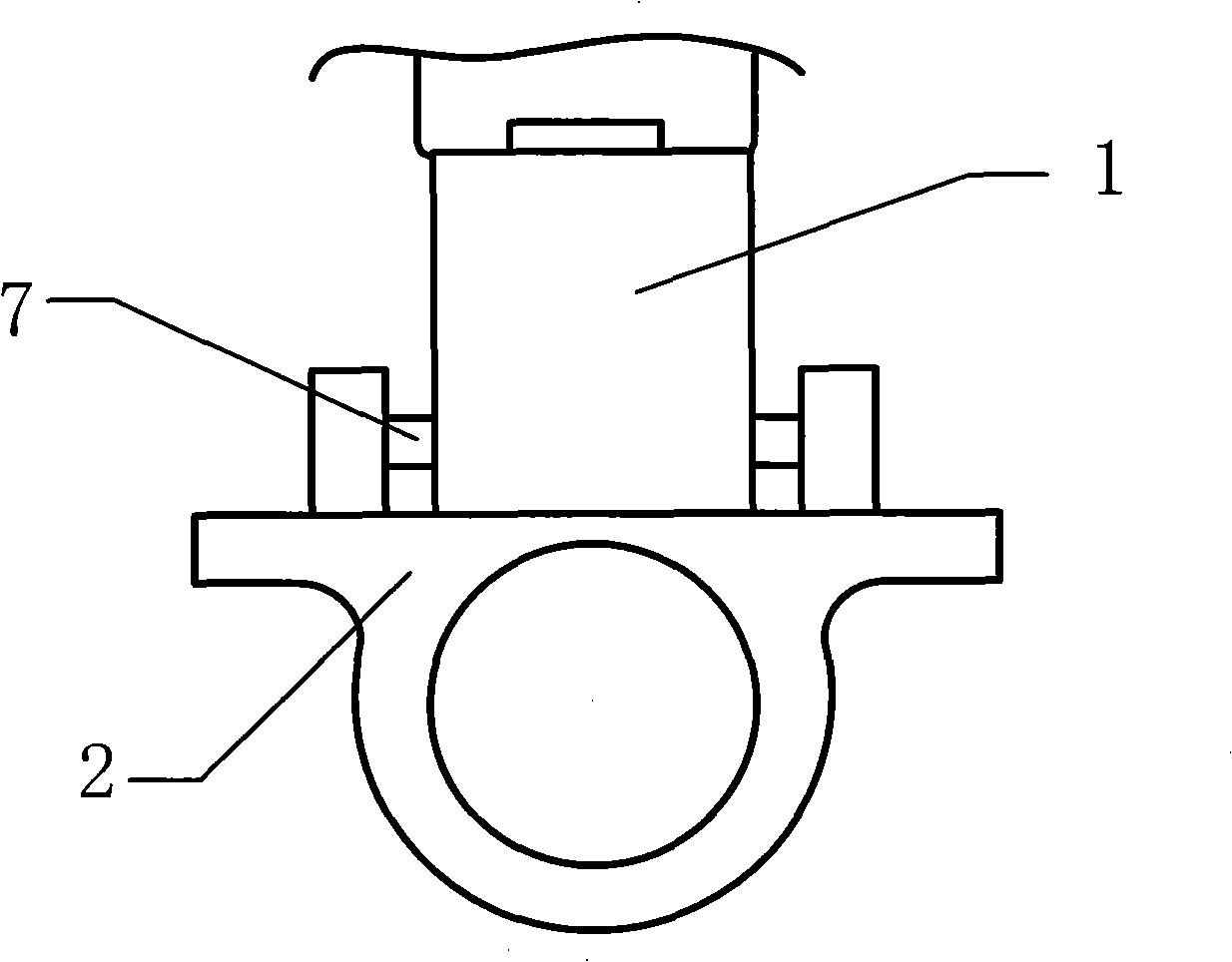

[0022] Such as Figure 1~3 As shown, a belt deviation correction mechanism of a sander includes a coupling seat 1, a bearing housing 2, and a deviation correction cylinder. The end of the tension roller 8 installed on the light machine extends into the connection end of the bearing seat 2, and one side of the bearing seat 2 is extended with a mounting block 4, and the central beam on the sanding machine is provided with a joint end 5, the mounting block 4, the joint end Between 5, a deviation correction cylinder is added.

[0023] According to a preferred embodiment of the present invention, the deviation correction cylinder adopts a double-connected cylinder 3 . Such as figure 1 As shown, one end of the piston rod of the double-connected cylinder 3 and the extended mounting block 4 on the bearing seat 2 are fixed by screws, and the other end of the piston rod is fixed on the joint end set on the central beam of the sander frame. 5 on. In order to make it easier for the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com