High overload and linear vibration composite test device

A technology for testing equipment and line vibration, applied in the field of inertial navigation testing, can solve problems such as burnout, complex equipment structure, and large volume, and achieve the effects of convenient debugging and maintenance, simplified equipment structure, and good manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

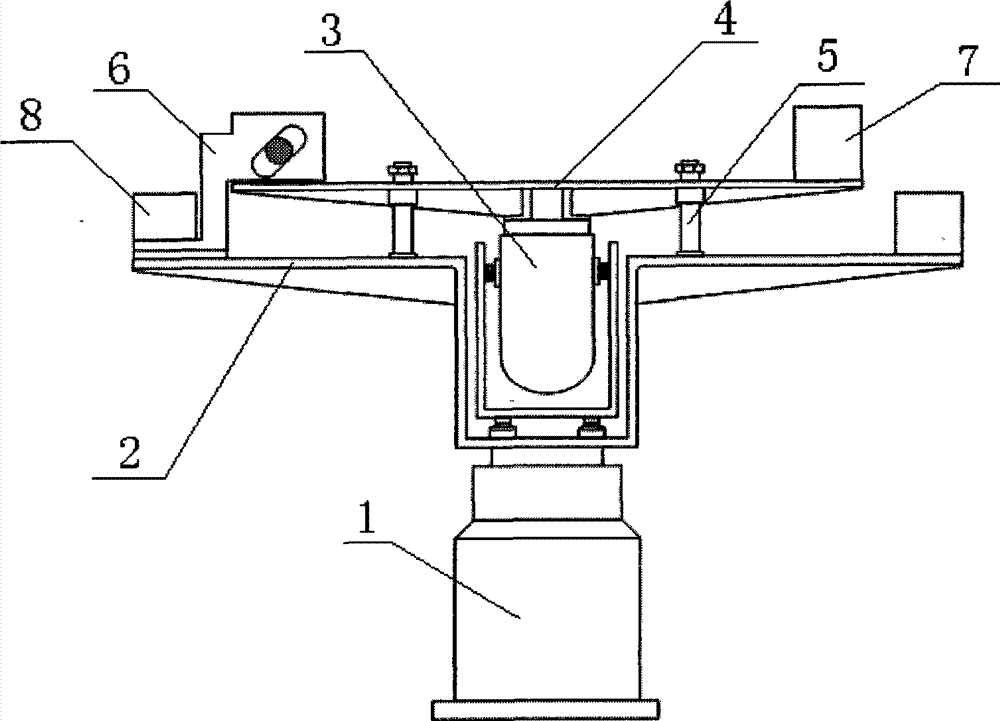

[0015] Example 1: Combining image 3 , the present invention is a large overload and linear vibration composite test device, which is composed of a disc centrifuge, a vibrating beam, a direction-changing fixture, etc., the direction-changing fixture is installed on the edge of the disc centrifuge, At the center of the disc centrifuge, the vibrator can be adjusted through the centering device, and the speed of the disc centrifuge and the vibration frequency of the vibrator can be adjusted.

[0016] 1. Horizontal vibration of the product under test - large overload compound movement

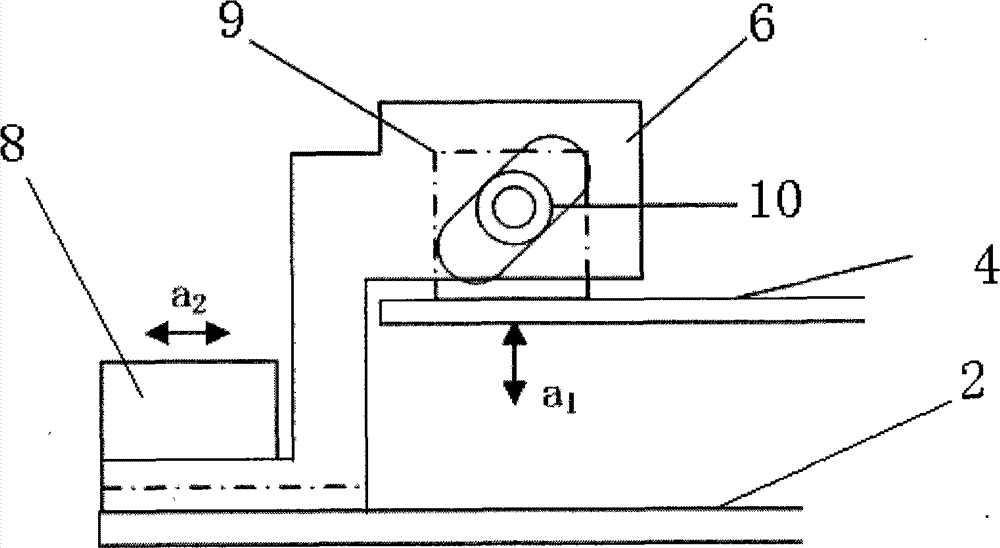

[0017] Such as figure 1 As shown, the vibrator is vertically installed in the center of the centrifuge, and the vibration source is transmitted to the product under test through the clamp on the vibrating beam. The fixture has variable guide grooves to change the vertical vibration of the vibrator into the horizontal vibration of the product under test.

[0018] The variable direction vibration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com