Method of producing bicycle frame using 3D printing technology

A 3D printing and bicycle technology, applied in bicycle racks, bicycle accessories, applications, etc., can solve the problems of low product standardization rate, inconvenient fine standardization requirements, and low product quality control, so as to reduce the time of manual operation and eliminate The effect of poor anisotropy and easy product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] As a preferred embodiment of the present invention, with reference to the attached figure 1 To attach Figure 14 , this embodiment discloses a method for producing a bicycle frame using 3D printing technology, and this embodiment includes:

[0062] A method for producing a bicycle frame using 3D printing technology, comprising the following steps:

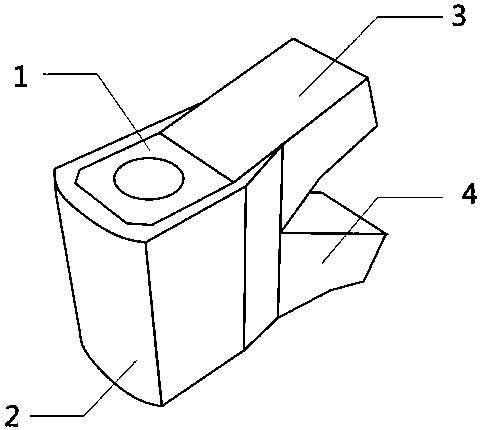

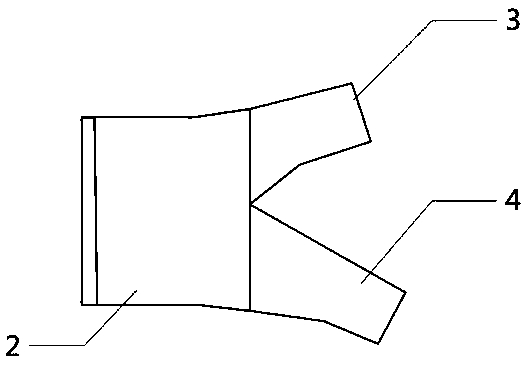

[0063] A. Divide the frame into multiple structural parts, the structural parts include the head tube 1, the plug side plate 2, the upper tube 3 and the down tube 4; the head tube 1, the plug side plate 2, the upper tube 3 and the lower tube 4 are provided with a plug-in structure;

[0064] B. Use 3D printing technology to standardize the production of each structural part;

[0065] C. Connect the upper pipe 3 and the lower pipe 4 with the head pipe 1 respectively; then connect them with the side plate 2.

[0066] The side wall of the head pipe 1 is provided with a socket projection one 5, a socket socket one 9 and a soc...

Embodiment 2

[0084] As a preferred embodiment of the present invention, with reference to the attached figure 1 To attach Figure 14 , this embodiment discloses a method for producing a bicycle frame using 3D printing technology, and this embodiment includes:

[0085] A method for producing a bicycle frame using 3D printing technology, comprising the following steps:

[0086] A. Divide the frame into multiple structural parts, the structural parts include the head tube 1, the plug side plate 2, the upper tube 3 and the down tube 4; the head tube 1, the plug side plate 2, the upper tube 3 and the lower tube 4 are provided with a plug-in structure;

[0087] B. Use 3D printing technology to standardize the production of each structural part;

[0088] C. Connect the upper pipe 3 and the lower pipe 4 with the head pipe 1 respectively; then connect them with the side plate 2.

Embodiment 3

[0090] As a preferred embodiment of the present invention, with reference to the attached figure 1 To attach Figure 14 , this embodiment discloses a method for producing a bicycle frame using 3D printing technology, this embodiment is basically the same as Embodiment 2, the difference is that:

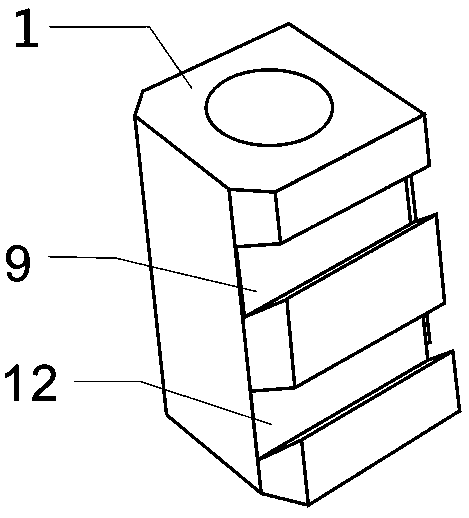

[0091] The side wall of the head pipe 1 is provided with a socket projection one 5, a socket socket one 9 and a socket socket two 12, the socket projection one 5 is arranged along the axial direction of the head pipe 1, and the socket socket Connecting slot one 9 and plugging slot two 12 are arranged in parallel, there are two plugging slots one 9 and two plugging slots 12, and the two plugging slots 19 are respectively arranged on the side walls of two non-adjacent head tubes 1 , the two insertion slots 12 are respectively arranged on the side walls of the two non-adjacent head tubes 1; the insertion slots 9 and 12 are both vertical to each other in space with the insertion bump 1; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com