Composite filter element assembly and water purifier

A composite filter element and component technology, applied in the field of water treatment, can solve the problems of complicated replacement of filter element components, water leakage, large occupied volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

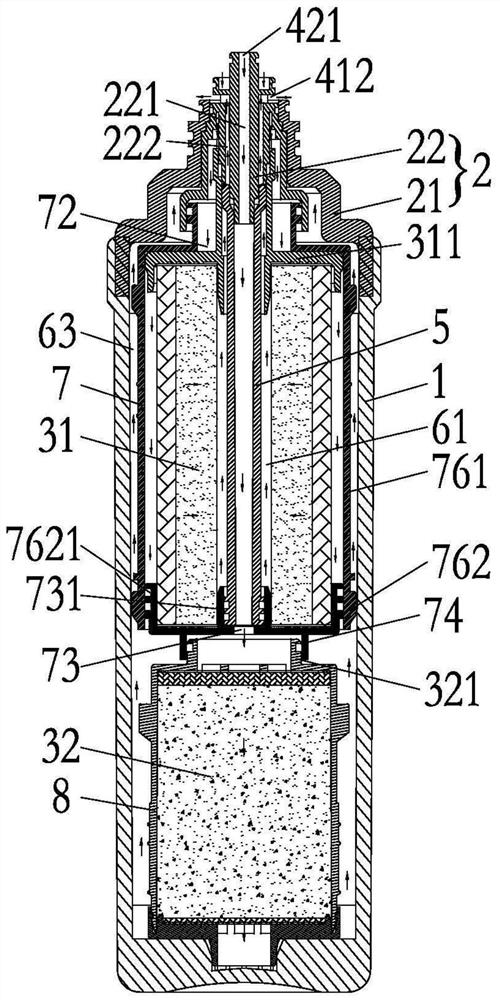

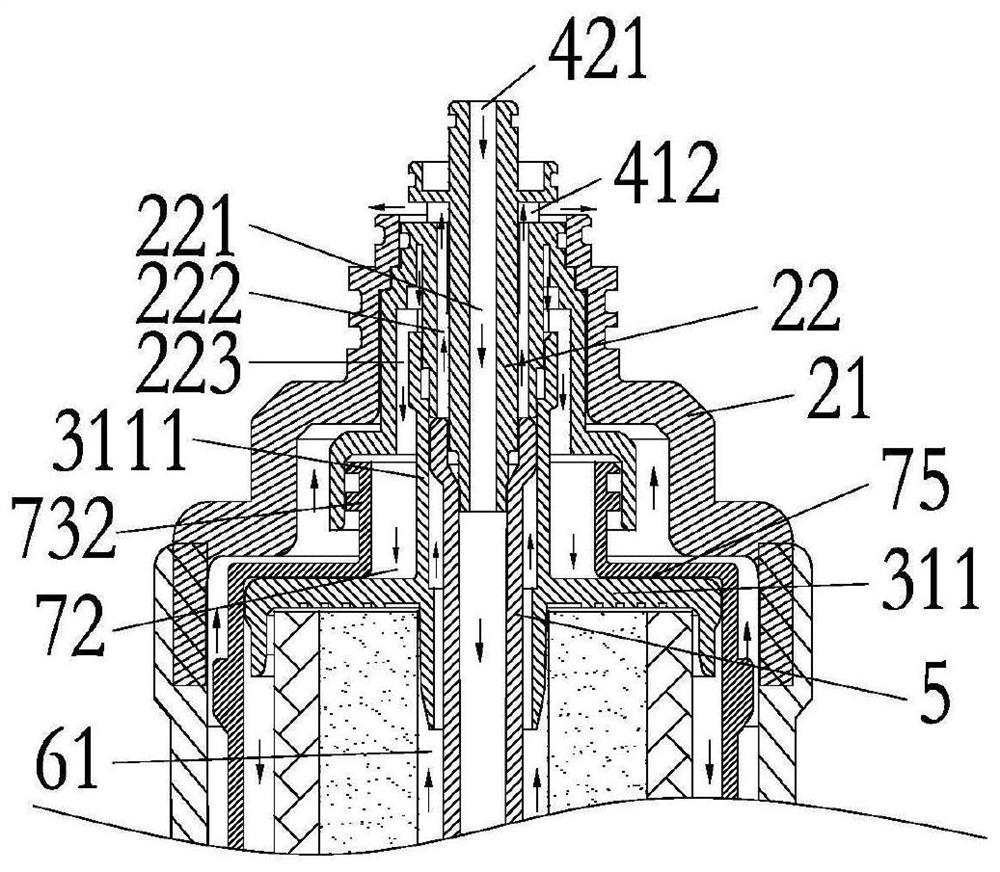

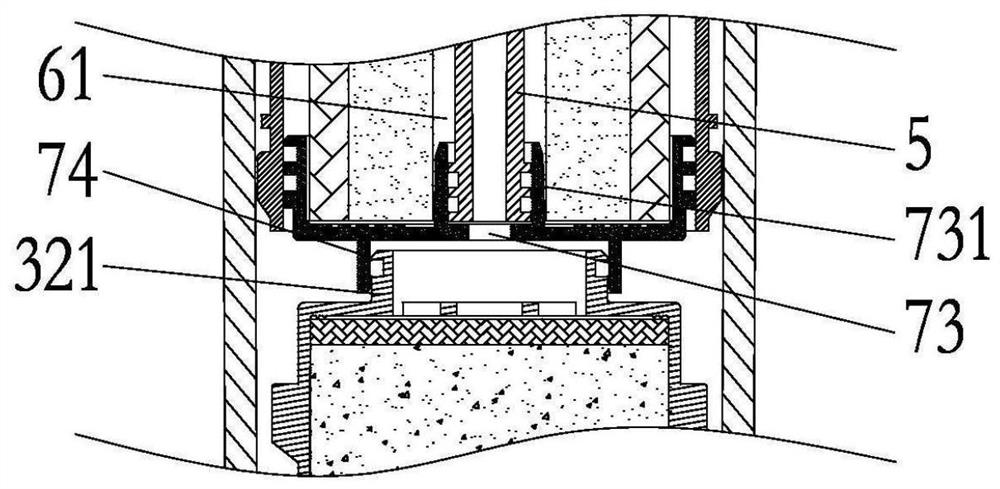

[0054] Such as Figure 1-Figure 5 As shown, a composite filter element assembly includes a housing 1 and an installation head 2, the installation head 2 is located at one end of the housing 1, the installation head 2 includes an outer end cover 21, and the filter material inside the filter element assembly is loaded into the housing through the opening at the upper end of the housing 1 1, the outer end cover 21 is welded and fixed on the opening of the upper end of the shell 1. The composite filter element assembly also includes a first filter element 31 and a second filter element 32 , wherein the first filter element 31 and the second filter element 32 are arranged axially, and the first filter element 31 is located between the second filter element 32 and the installation head 2 . The first filter element 31 and the second filter element 32 are respectively located in the first waterway and the second waterway, wherein the first waterway and the second waterway are separate...

Embodiment 2

[0073] Such as Figure 9-Figure 13As described above, a composite filter element assembly includes a housing 1a and an installation head 2a, the installation head 2a is located at one end of the housing 1a, and the installation head 2a includes an outer end cover 21a and a waterway converter 22a. The composite filter element assembly also includes a first filter element 31a and a second filter element 32a, wherein the first filter element 31a and the second filter element 32a are arranged axially, and the first filter element 31a is located between the second filter element 32a and the installation head 2a. The first filter element 31a and the second filter element 32a are respectively located in the first waterway and the second waterway, wherein the first waterway and the second waterway are separated from each other, the first waterway includes a first water inlet 411a and a first water outlet 412a, and the first waterway includes a first water inlet 411a and a first water o...

Embodiment 3

[0082] Such as Figure 14-Figure 17 As shown, a composite filter assembly includes a housing 1b and an installation head 2b, the installation head 2b is located at one end of the housing 1b, and the installation head 2b includes an outer end cover 21b and a waterway converter 22b. The composite filter element assembly also includes a first filter element 31b and a second filter element 32b, wherein the first filter element 31b and the second filter element 32b are arranged axially, and the first filter element 31b is located between the second filter element 32b and the installation head 2b. The first filter element 31b and the second filter element 32b are respectively located in the first waterway and the second waterway, wherein the first waterway and the second waterway are separated from each other, the first waterway includes a first water inlet 411b and a first water outlet 412b, and the first waterway includes a first water inlet 411b and a first water outlet 412b. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com