Physiologically active substance-containing granular composition and method of producing the same

A technology for physiologically active substances and compositions, which is applied to the field of granular compositions containing physiologically active substances and their preparation, can solve the problems of limited use, poor thermal stability, cumbersome drying steps, etc., and achieves improvement in low recovery rate and good operability. , good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0121] In the preparation method of the present invention, the emulsified particle size of the oily component (A) containing physiologically active substances in the above-mentioned oil-in-water emulsion composition is preferably in the range of 0.01 to 50 μm, more preferably in the range of 0.01 to 20 μm, most preferably in the range of 0.01 ~10μm range. When the average particle diameter of the oily component (A) in an oil-in-water emulsion composition exceeds 50 micrometers, the oral absorbability of the obtained granular composition may fall. On the contrary, when the average particle size of the oily component (A) in the oil-in-water emulsion composition is less than 0.01 μm, it is often difficult to maintain the stability of the emulsion droplets during the preparation process. By controlling the particle size of the emulsified liquid droplets in this step, the domain particle size in the obtained granular composition can be controlled.

[0122] The emulsified particle ...

Embodiment 1

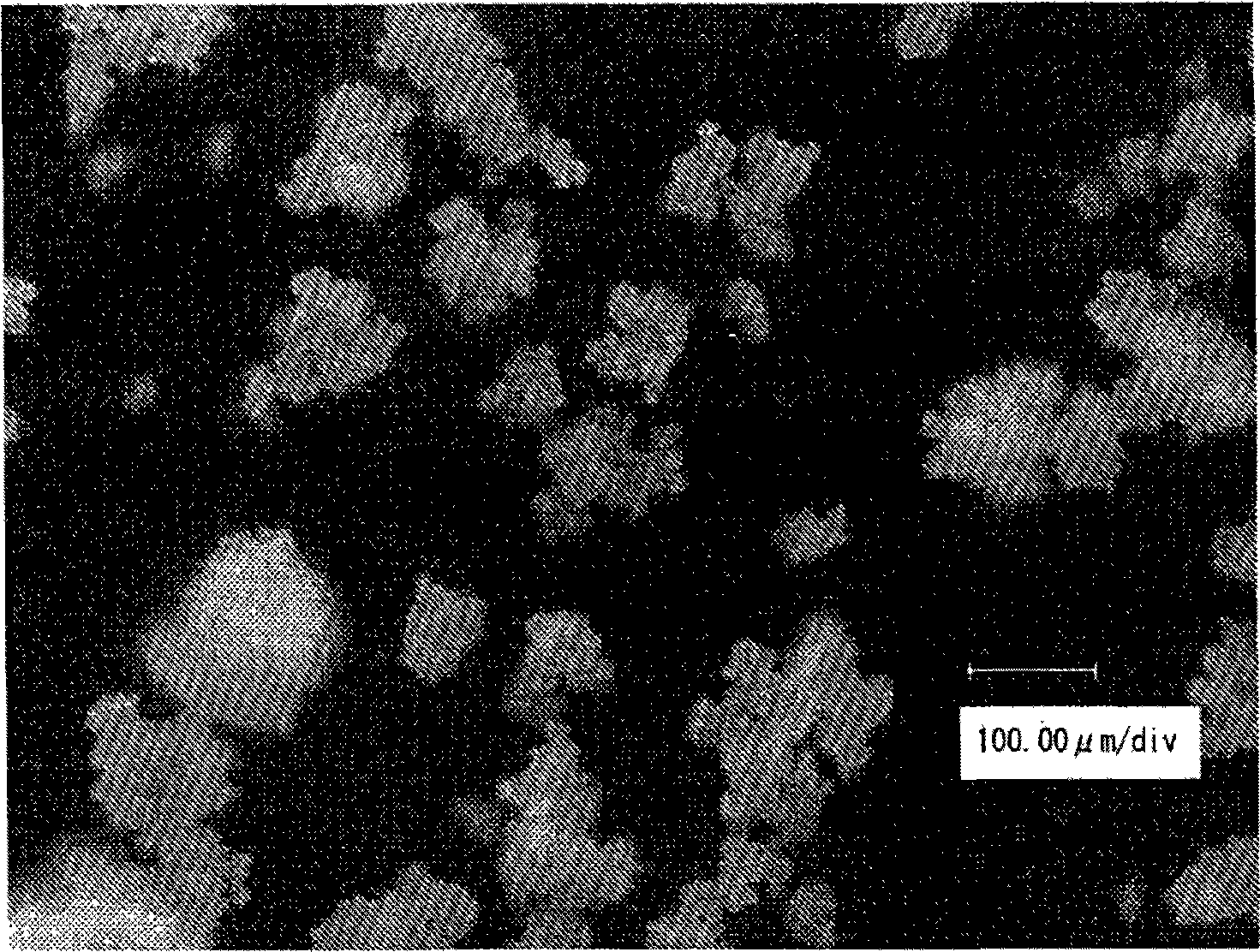

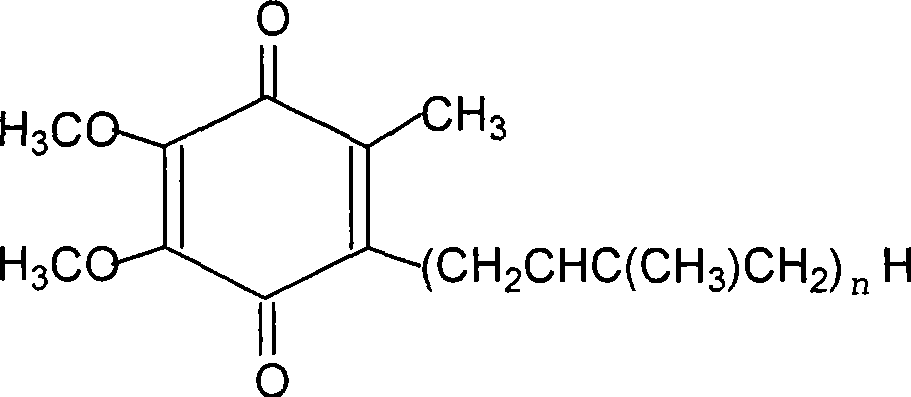

[0157] At 60°C, make 6g gum arabic ( Naturels; EFICACIA-M) was dissolved in 24 g of distilled water to obtain an aqueous solution of a water-soluble excipient. Separately, 4 g of oxidized coenzyme Q10 (manufactured by Kaneka Co., Ltd.; Kaneka Coenzyme Q10) was dissolved at 60°C in an oily component (A) which was added to a water-soluble vehicle solution at 60°C. It emulsified at 10000 rpm x 6 minutes, and obtained the oil-in-water type emulsion composition. The emulsified particle size of oxidized coenzyme Q10 in the oil-in-water emulsion composition is about 1 μm. 34g of the obtained oil-in-water emulsified composition was added to the oily component (B) preheated to 100°C while stirring to prepare an oil-in-water-in-oil (O / W / O) emulsion, the oily component ( B) Consists of 60 g of MCT (Acter M-2 manufactured by Riken Vitamin Co., Ltd.) and 12 g of surfactant (triglyceryl pentaoleate: SY-GlysterPO-3S manufactured by Sakamoto Pharmaceutical Co., Ltd., HLB3.0). In addition...

Embodiment 2

[0161] The amount of gum arabic was changed to 4g, and the amount of oxidized coenzyme Q10 was changed to 6g. Except that, the same method as described in Example 1 was used to obtain a granular composition containing oxidized coenzyme Q10. The average particle diameter of the obtained granular composition was 662 μm, the sphericity was 0.94, and the average particle diameter of the oxidized coenzyme Q10 region was 1845 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com