Water cooling method for vehicle lithium power cell set and device thereof

A power battery pack and water cooling device technology, which is applied to secondary batteries, circuits, electrical components, etc., can solve problems such as uneven heat dissipation, poor cooling effect, and unbalanced lithium power batteries, so as to ensure safety and reliability , to achieve heat balance management, to overcome the effect of poor heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

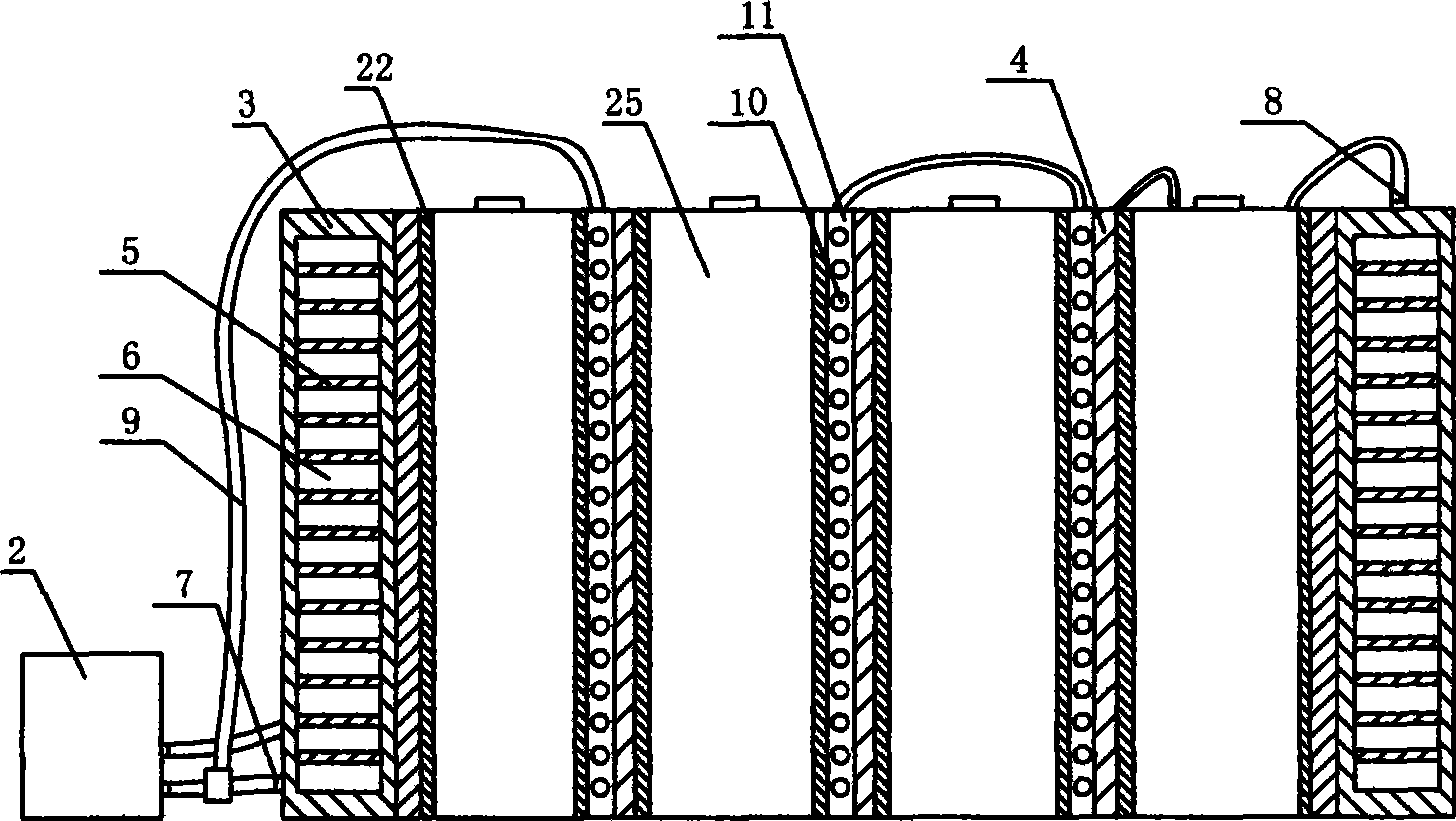

[0016] The subject of the water-cooling method for a lithium power battery pack for a vehicle according to the present invention is that, in addition to installing a circulating water cooling device on the surface of the lithium power battery pack, it is also necessary to cool down between adjacent battery cells that are prone to heat accumulation Treatment design to achieve a balanced cooling process to ensure the overall performance and service life of the lithium power battery pack.

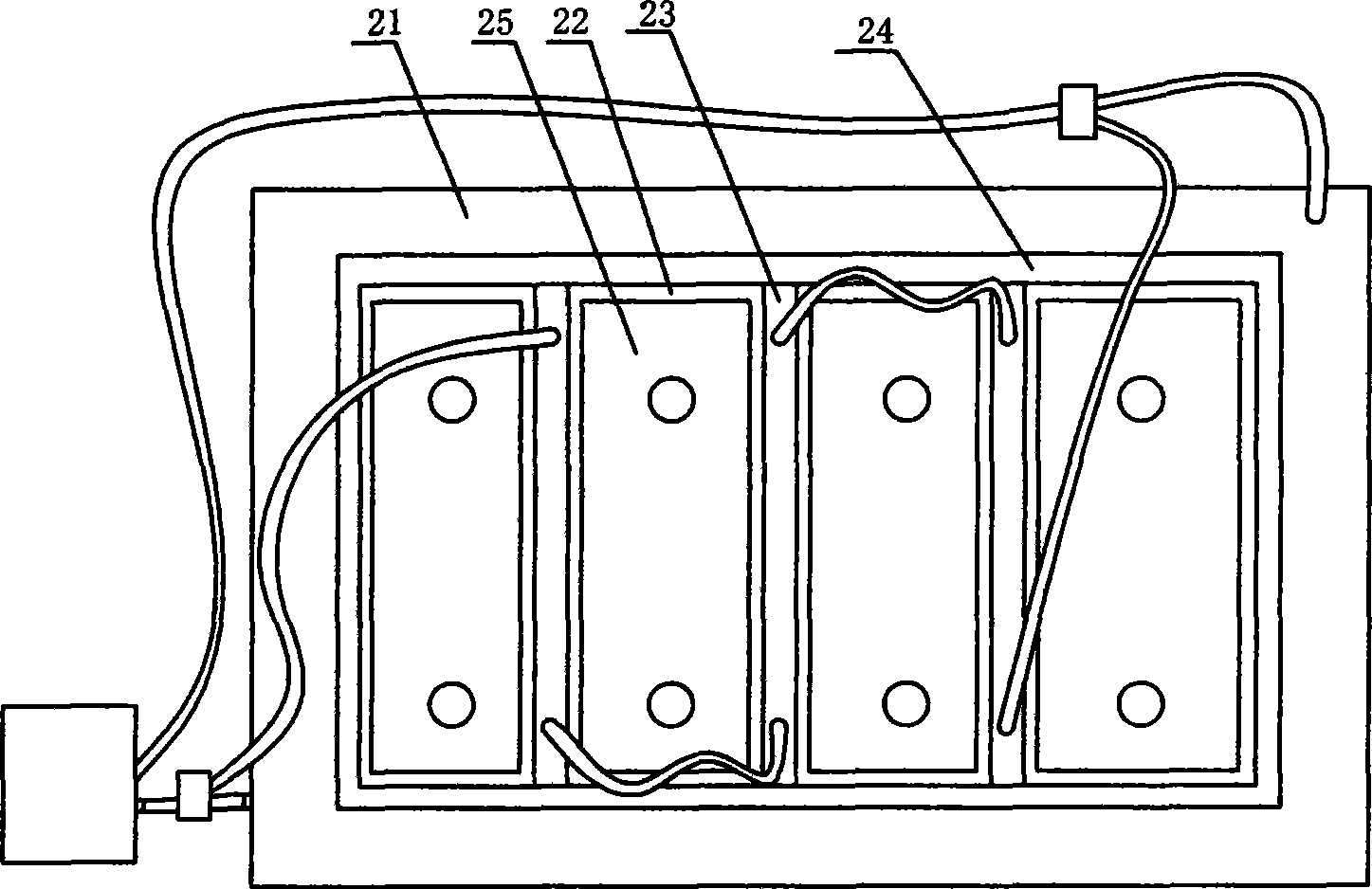

[0017] Such as figure 1 As shown, the water-cooling method for a lithium power battery pack for a vehicle according to the present invention includes installing an external circulating water cooling device 21 on the surface of the lithium power battery pack and installing an internal circulating water cooling device on one side of each battery core casing 22 23. Among them, the internal circulating water cooling device 23 is directly processed on the side of the battery core case 22 during the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com