Method for manufacturing lithium ion battery

A technology of lithium-ion batteries and manufacturing methods, which is applied in the direction of electrolyte battery manufacturing, secondary batteries, and battery pack parts, etc., which can solve the problems of wasting packaging bag materials, aluminum-plastic composite film packaging materials, damaging battery performance, and general low-vacuum pumping. Gas heat sealing equipment and other issues, to achieve the effect of simple process flow and improved manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

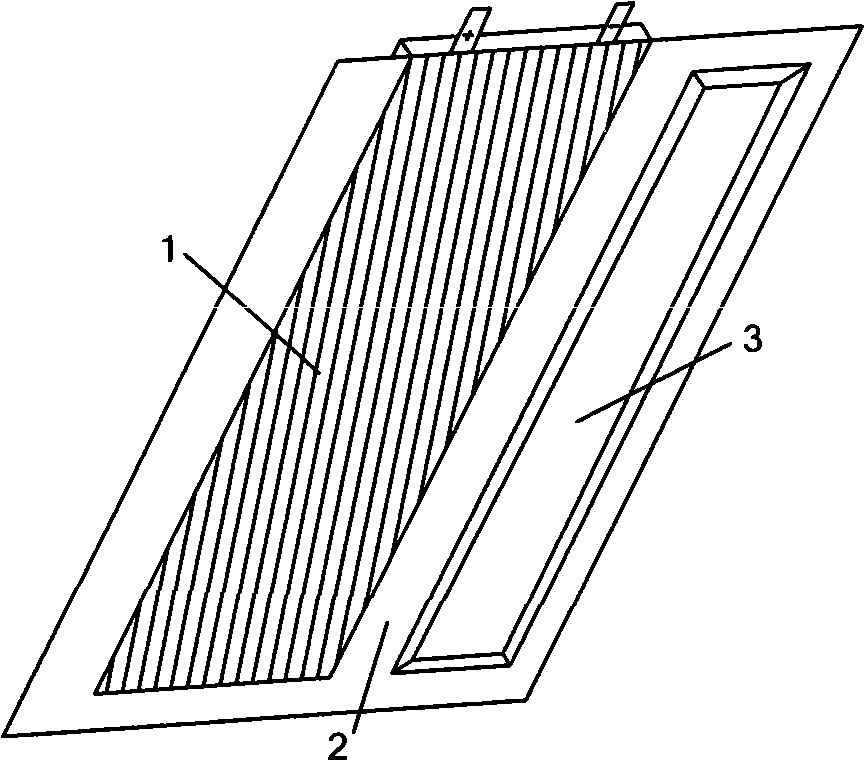

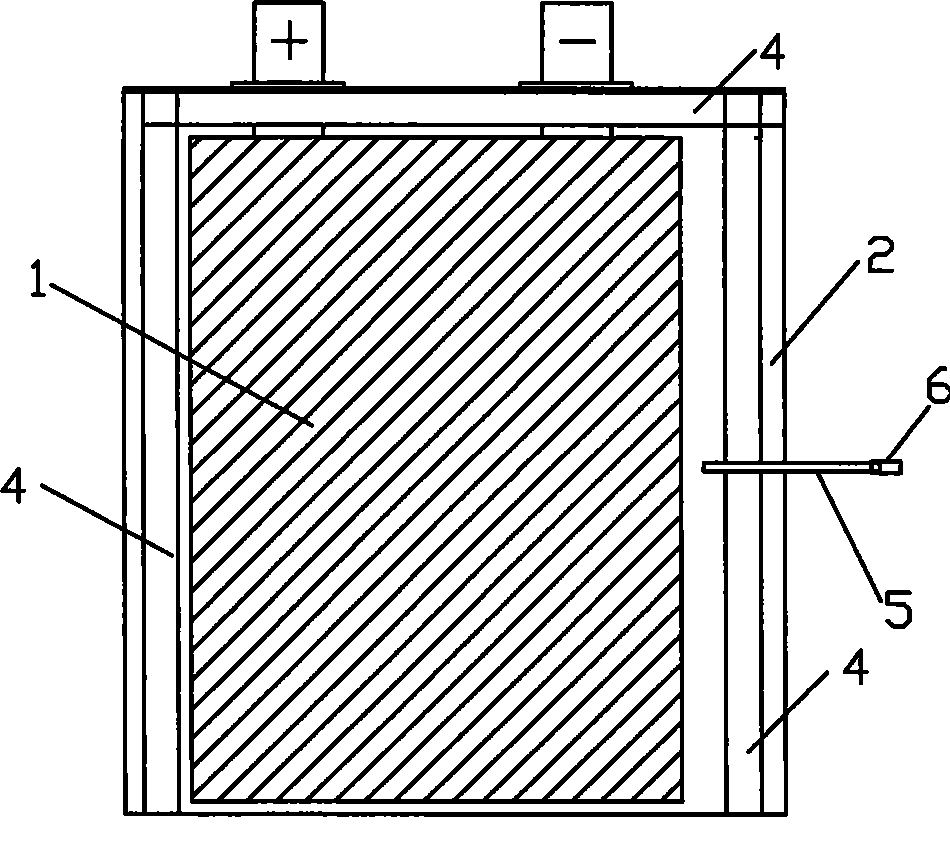

Image

Examples

Embodiment 1

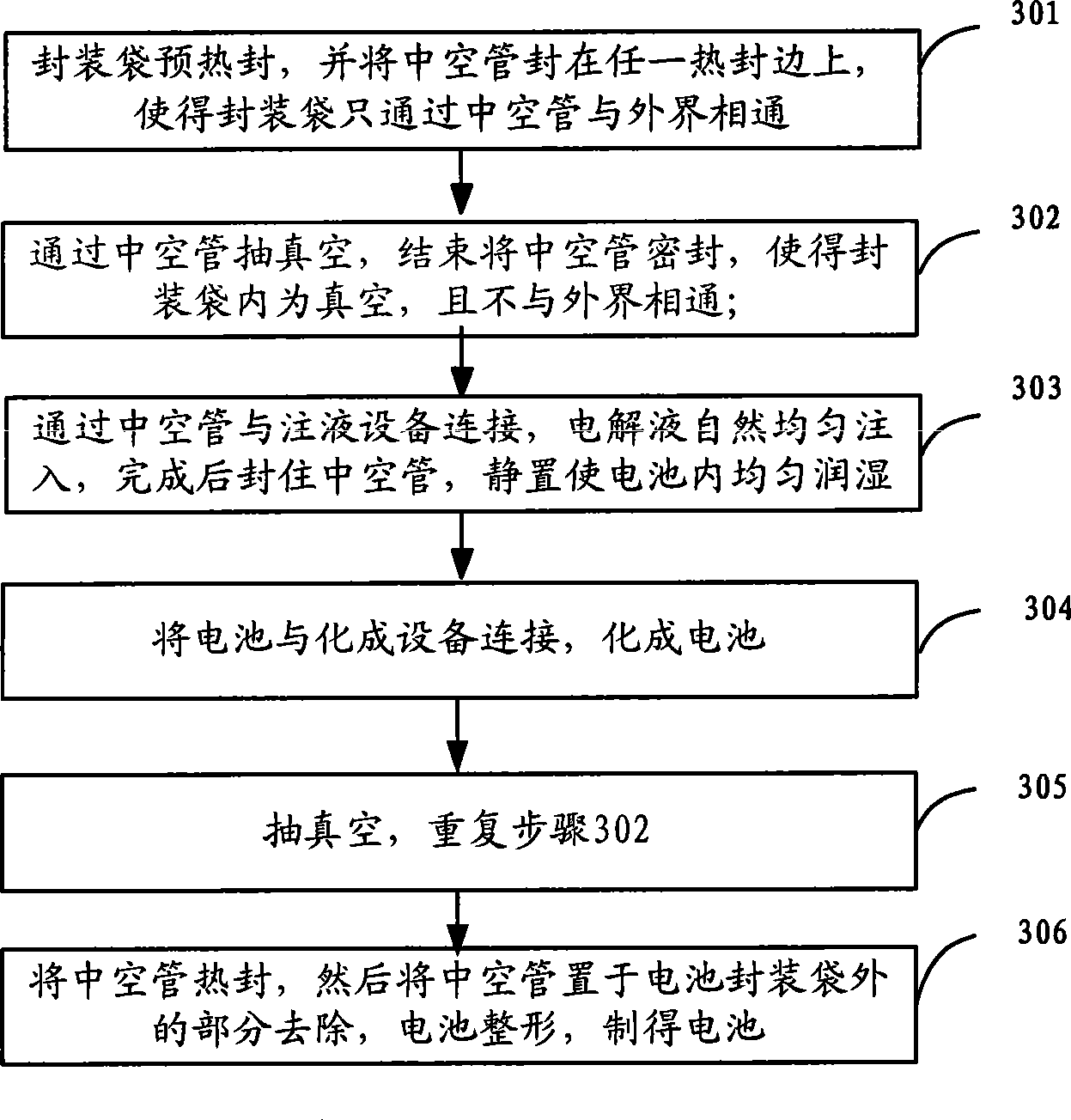

[0044] Such as image 3 Shown, the embodiment one of the manufacturing method of the lithium-ion battery provided by the present invention comprises the following steps:

[0045] Step 301: Preheat sealing of the packaging bag: put the battery core into the packaging bag, heat seal the other heat-sealed sides of the packaging bag tightly, and then place the opening of one end of a hollow tube in the heat-sealed side of the packaging bag , the other end opening is placed outside the packaging bag, a metal wire is built into the hollow tube when heat sealing, and the metal wire can be removed after sealing, so that the packaging bag only communicates with the outside world through the hollow tube;

[0046] Step 302: Vacuuming: Connect the hollow tube to the exhaust pipe of the vacuum equipment, and vacuumize the packaging bag. When the vacuum degree in the packaging bag meets the requirements of the lithium-ion battery manufacturing process, clamp the hollow tube and disconnect i...

Embodiment 2

[0053] Such as Figure 4 As shown, this embodiment is the same as other steps of the method described in the above-mentioned embodiment 1, the difference is:

[0054] Step 401: During the pre-heat sealing process, in addition to communicating with the outside world through the hollow tube, a heat-sealed side is also reserved as a liquid injection side or a liquid injection hole is reserved on a heat-sealed side for liquid injection ;

[0055] Step 402: Vacuuming: Seal the hollow tube with a rubber cap, and then connect the vacuuming device to the packaging bag through the reserved liquid injection edge or liquid injection hole to perform vacuuming;

[0056] Step 403 is: filling dry gas, and then completing the liquid injection process through the reserved liquid injection edge or the liquid injection through hole, and heat sealing the liquid injection edge or the liquid injection through hole after the liquid injection is completed.

[0057] Step 405: Open the rubber cap of ...

Embodiment 3

[0059] Such as Figure 5 , Image 6 As shown, this embodiment is the same as the other steps of the method described in the above-mentioned embodiment 1 or embodiment 2, the difference is that in the formation step, the battery is formed and vacuum is applied at the same time, so that the residual in the battery can be removed during the formation. The gas and the newly generated gas during the formation process are discharged to realize the formation in a vacuum state. When the battery is formed, the pressure is uniform, and the residual gas in the battery or the gas generated by the formation is effectively prevented from accumulating in the battery, thereby achieving the effect of improving battery performance.

[0060] The manufacturing method of the above-mentioned lithium-ion battery is applicable to the production of soft-packed lithium-ion batteries of various capacities, shapes and sizes. The process is simple and the equipment cost is low, which can effectively save...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com