Method for encapsulating pervious crystalline silicon solar cell modules

A technology for solar cell components and packaging methods, applied in electrical components, semiconductor devices, circuits, etc., can solve the problems of large equipment investment, long lamination cycle, displacement, etc., to simplify the process, reduce equipment investment, and facilitate application. The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

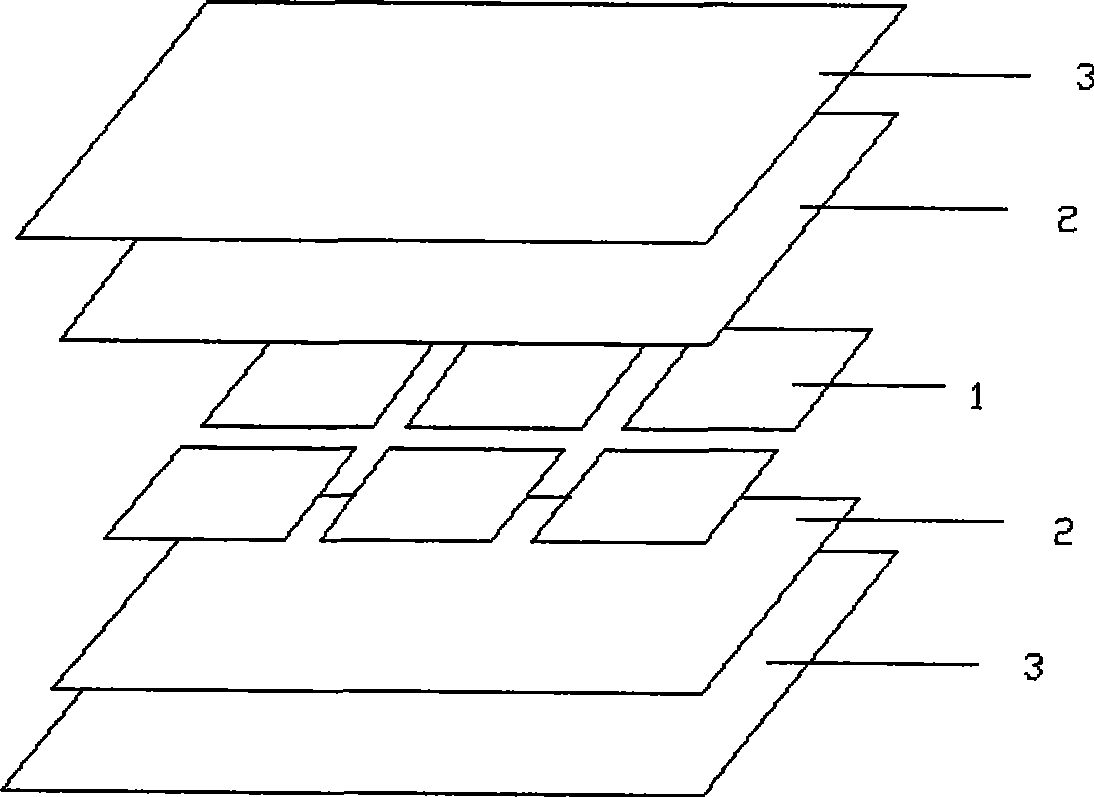

[0026] Such as figure 1 As shown, first place a piece of low-iron tempered glass 3 flat on the table, and spread a single layer of EVA film 2 with a thickness of 0.25mm on it, and place the series-parallel connected solar battery strings 1 on the EVA film 2, A single layer of EVA film 2 with a thickness of 0.25 mm and low-iron tempered glass 3 are also laid in sequence on the solar cell string 1 to form low-iron tempered glass 3-EVA film 2-series-parallel connected solar cells String 1-EVA film 2-low-iron tempered glass 3 five-layer superimposed structure; EVA film 2 is marked with multiple horizontal and vertical marks to reduce unidirectional shrinkage of the EVA film. Then use two layers of polymer polyester film PC to wrap the five-layer superimposed structure. The edge of the PC film needs to exceed the edge of the five-layer superimposed structure; When the board temperature reaches this temperature, put the above-mentioned processed five-layer superimposed structure in...

Embodiment 2

[0028] Such as figure 1 As shown, first place a piece of low-iron tempered glass 3 flat on the table, and lay a single layer of EVA film 2 with a thickness of 0.25mm on it, and place the solar cell strings 1 connected in series and parallel on the EVA film 2, and place them on top of the EVA film 2. Two layers of EVA film 2 with a single layer thickness of 0.25mm and low-iron tempered glass 3 are also stacked in sequence on the solar cell string 1 to form a low-iron tempered glass 3-EVA film 2-series-parallel solar cell string 1-EVA film 2-Five-layer superimposed structure of low-iron tempered glass 3; EVA film 2 is marked with multiple horizontal and vertical lines to prevent unidirectional shrinkage of the EVA film. Then use two layers of polymer polyester film PC to wrap the five-layer superimposed structure. The edge of the PC film needs to exceed the edge of the five-layer superimposed structure; When the plate temperature reaches this temperature, put the above-treated ...

Embodiment 3

[0030] Such as figure 1 As shown, first place a piece of low-iron tempered glass 3 flat on the table, and spread a single layer of EVA film 2 with a thickness of 0.25mm on it, and place the series-parallel connected solar battery strings 1 on the EVA film 2, Three layers of EVA adhesive film 2 with a thickness of 0.25 mm and low-iron tempered glass 3 are also stacked in sequence on the solar cell string 1 to form low-iron tempered glass 3-EVA adhesive film 2-series-parallel solar cells String 1-EVA film 2-low-iron tempered glass 3 five-layer superimposed structure; EVA film 2 is marked with multiple horizontal and vertical lines to avoid unidirectional shrinkage of the EVA film. Then use two layers of polymer polyester film PC to wrap the five-layer superimposed structure. The edge of the PC film needs to exceed the edge of the five-layer superimposed structure; When the plate temperature reaches this temperature, put the above-treated five-layer superimposed structure into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com