Biomass power plant fuel system

A biomass fuel and biomass technology, applied in the directions of fuel supply, combustion method, combustion equipment, etc., can solve the problem that the yellow straw cannot adapt to the characteristics of loose foam and soft foam, it is difficult to realize the quiet layer combustion of the grate, and the straw winding auger and other problems, to achieve the effect of reducing intermediate crushing links, improving coking, and improving performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

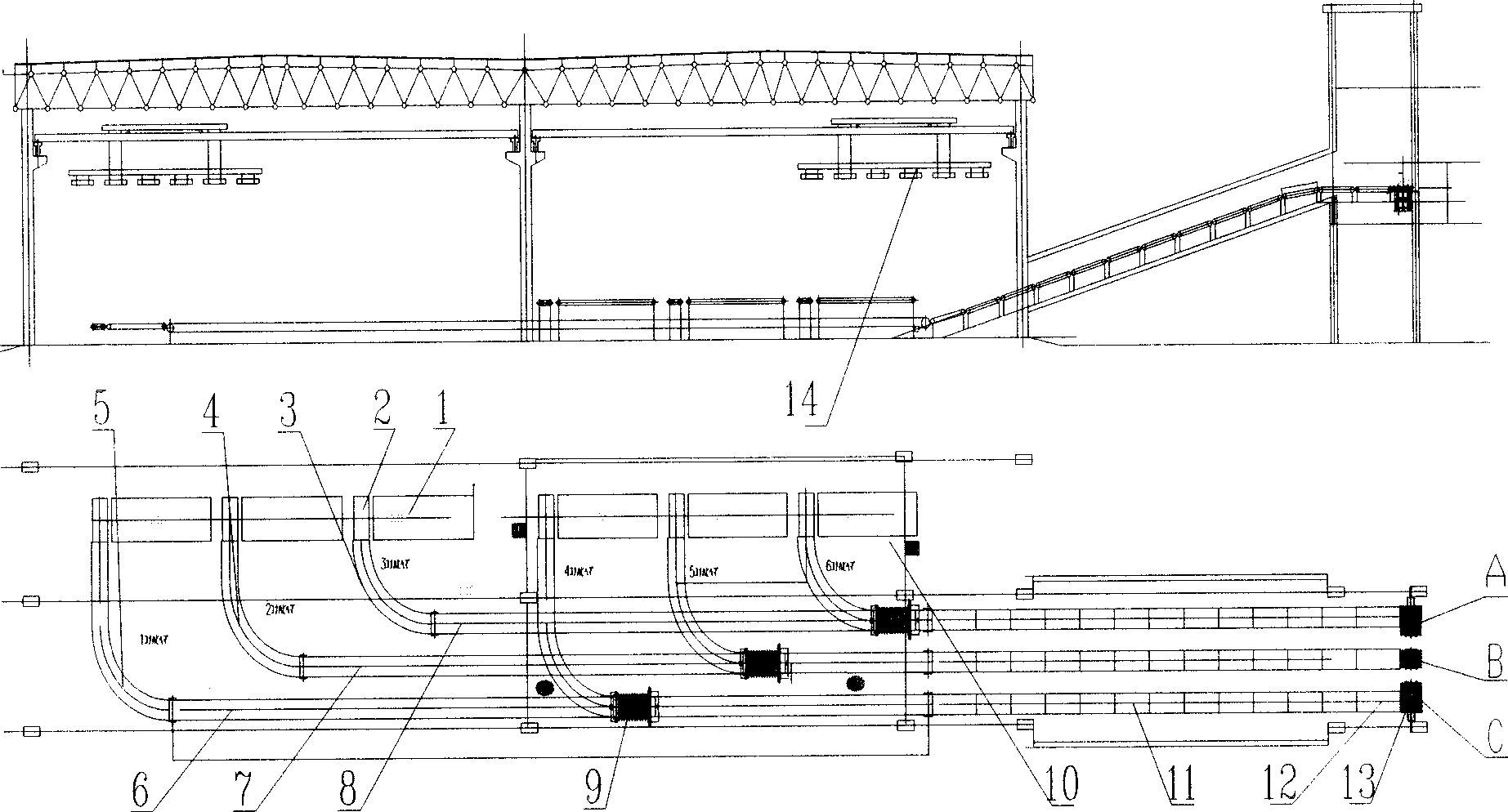

[0051] For the convenience of description, the daily operating hours of the power plant are 24 hours, and the average daily load rate is 0.833. The unbalance coefficient of fuel transportation is taken as 1.2, the combustion capacity of each boiler is 18 tons / hour, the fuel delivery capacity in front of the furnace is 80 seconds / bag, and the fuel delivery line in front of the furnace is used as an example.

[0052] 5.1 Baler

[0053] It can be concluded that the weight of a single bag is 200 kg, and the shape of the straw bag is determined to be 1.2×1×0.8 meters and the packing density is 0.21 tons / cubic meter.

[0054] (1) Packing density: The packing density must reach 0.21 tons / cubic meter or more, and the nominal pressure of the vertical straw baler is 1600KN.

[0055] (2) Fuel packaging shape and packaging compression direction: the shape of straw bales is 1.2×1×0.8 meters, the feeding direction of the baler is 0.8 meters, and the packaging compression direction is 1 met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com