Room temperature curing adhesive and application thereof

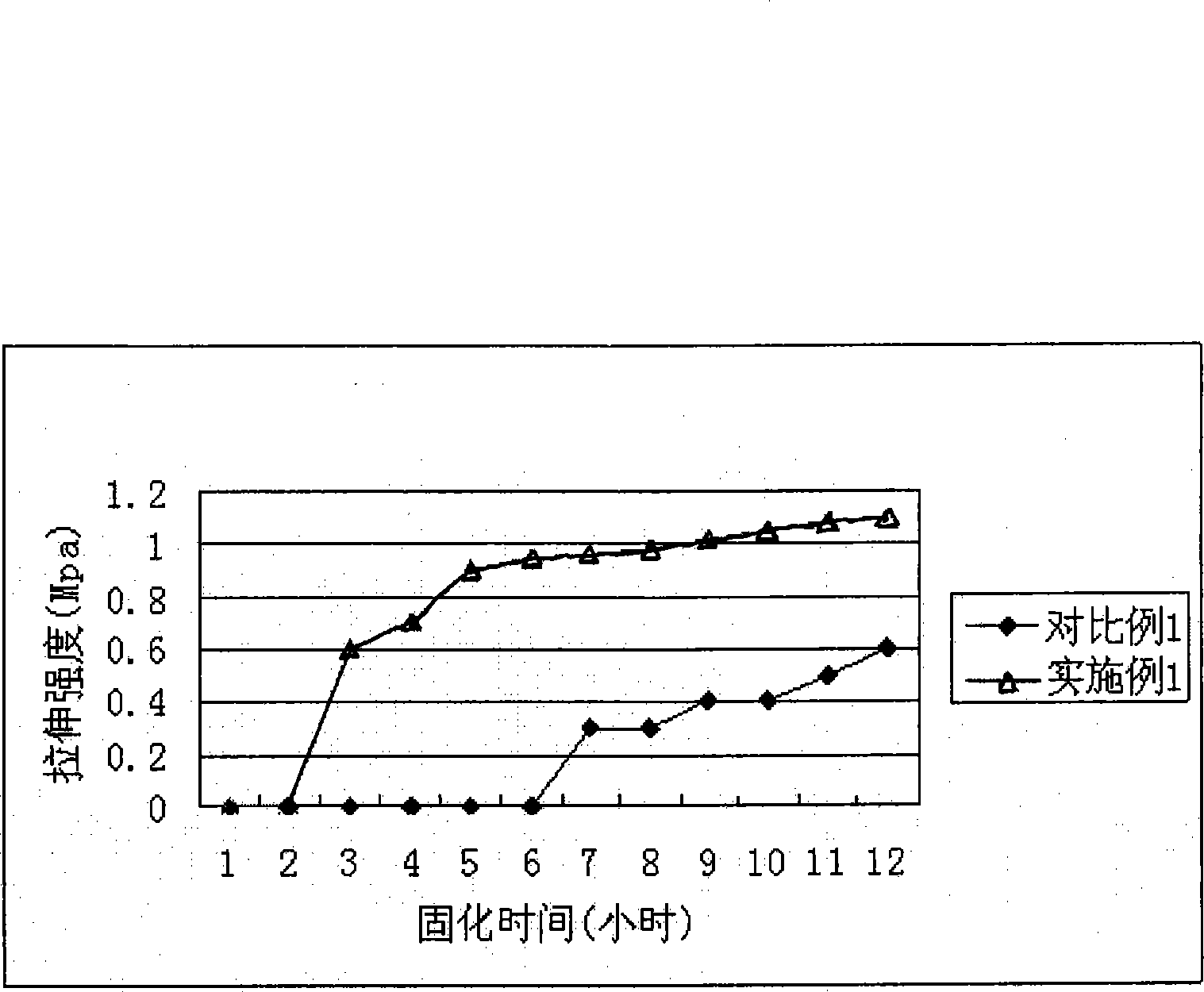

A room temperature curing and curing adhesive technology, which is applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of slow curing speed and achieve the effect of increased curing speed and short surface drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This example is used to illustrate the two-component room temperature curing adhesive provided by the present invention.

[0044] (1) Preparation of the first part of the two-component room temperature curing adhesive.

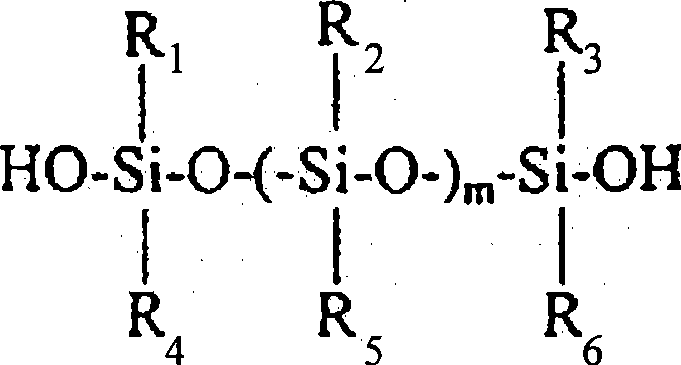

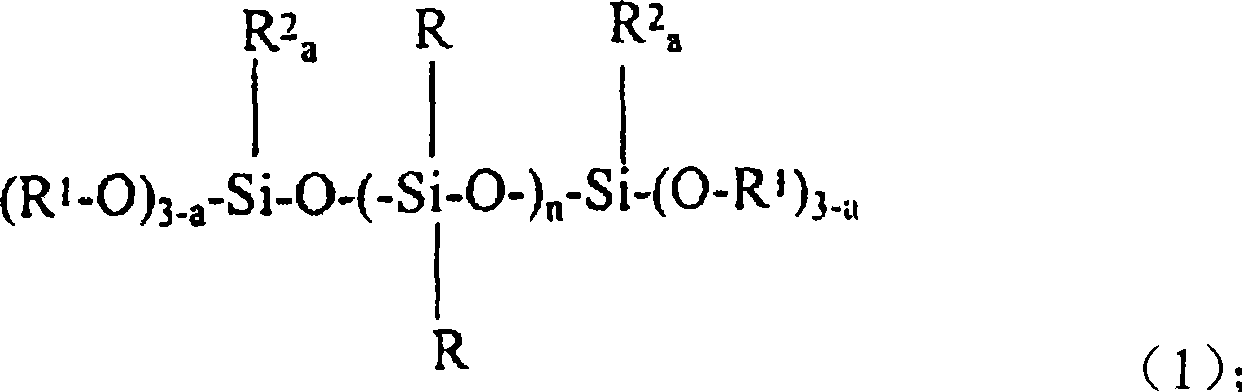

[0045] Under anhydrous conditions, based on the total amount of the first part, the hydroxyl-terminated dialkylsiloxane polymer: hydroxyl-terminated silicone oil (107 glue) 53.5%, filler: quartz powder 20%, CaCO 3 Powder 17.4%, SiO 2 2.5%, silane crosslinker: MeSi[ON=CMe(Et)] 3 2%, ViSi[ON=CMe(Et)] 3 3.2%, coupling agent: KH792 0.5%, KH560 0.54%, whitening agent: TiO 2 powder 0.30%, catalyst: dibutyl tin dilaurate 0.06%, mix evenly, that is the first part of room temperature curing glue.

[0046] (2) Preparation of the second part of the two-component room temperature curing silica gel.

[0047] In the air atmosphere, based on the total amount of the second part, plasticizer: 30% of dimethyl silicone oil (inert silicone oil), 32.5% of petroleum ...

Embodiment 2

[0059] This example is used to illustrate the two-component room temperature curing adhesive provided by the present invention.

[0060] (1) Preparation of the first part of the two-component room temperature curing adhesive.

[0061] Under anhydrous conditions, based on the total amount of the first part, the hydroxyl-terminated dialkylsiloxane polymer: hydroxyl-terminated silicone oil (107 glue) 50.9%, silane crosslinking agent ViSi[ON=CMe(Et) ] 3 7.1%, coupling agent: KH792 0.5%, KH560 0.6%, whitening agent: TiO 2 0.14%, catalyst: 0.06% of dibutyl tin dilaurate, filler: 40.7% of quartz powder and mix well, which is the first part of room temperature curing glue.

[0062] (2) Preparation of the second part of the two-component room temperature curing adhesive.

[0063] In the air atmosphere, based on the total amount of the second part, plasticizer: 30% of dimethyl silicone oil (inert silicone oil), 45.7% of petroleum ether (white oil), filler: CaCO 3 22.7%, Catalyst:...

Embodiment 3

[0065] This example is used to illustrate the two-component room temperature curing adhesive provided by the present invention.

[0066] (1) Preparation of the first part of the two-component room temperature curing adhesive.

[0067] Under anhydrous conditions, based on the total amount of the first part, the hydroxyl-terminated dialkylsiloxane polymer: hydroxyl-terminated silicone oil (107 glue) 51.1%, silane crosslinking agent: ViSi[ON=CMe(Et )] 36.6%, coupling agent: KH792 0.5%, KH560 0.5%, whitening agent: TiO 2 0.34%, Catalyst: 0.06% of dibutyltin dilaurate, 40.9% of filler, mixed evenly, which is the first part of room temperature curing glue.

[0068] (2) Preparation of the second part of the two-component room temperature curing silica gel.

[0069] In the air atmosphere, based on the total amount of the second part, plasticizer: 30% of dimethyl silicone oil (inert silicone oil), 45.5% of petroleum ether (white oil), filler: CaCO 3 22.6%, Catalyst: 0.97% of dibu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Adhesiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com