Highly directive antenna based on grooved cross metal strip artificial medium structure

A technology of artificial media and metal strips, which is applied to antenna combinations, antennas, leaky waveguide antennas with different interactions, etc., can solve the problems of processing error antenna performance, difficult precise positioning, inconvenient installation, etc., and achieve good directivity , Avoid antenna performance damage, easy to install and fix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

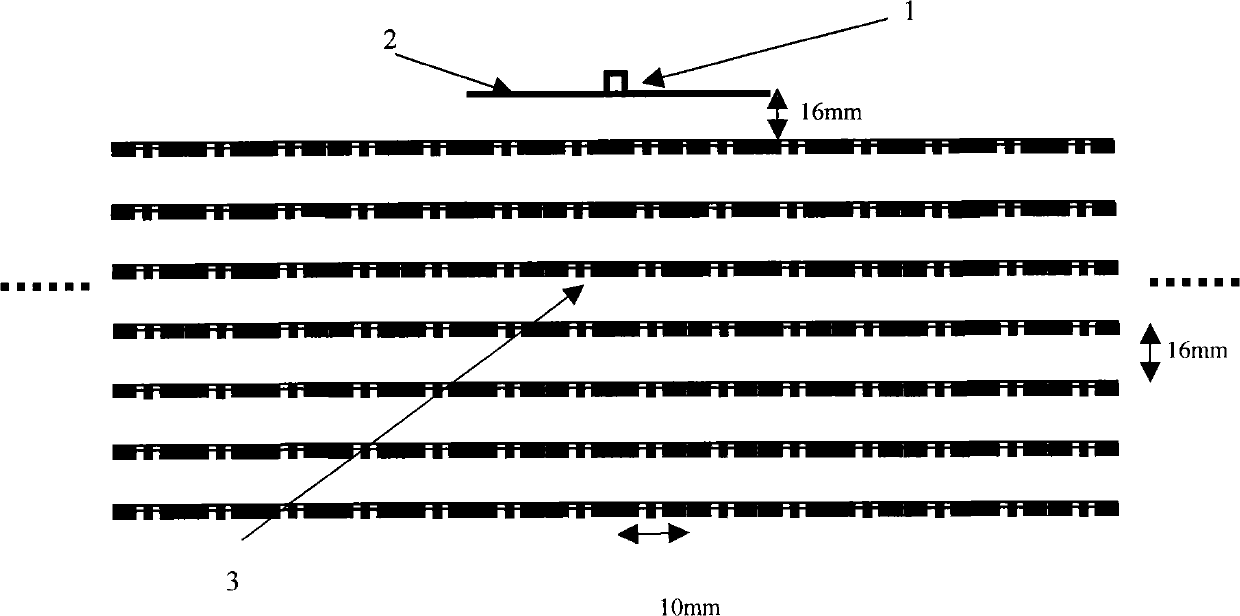

[0026] refer to figure 1 , this figure is a schematic diagram of the overall structure of the high-direction antenna provided by the present invention, including an SMA connector 1, a microstrip antenna array 2 and a radome 3 utilizing a slotted cross metal strip structure; feeding the microstrip antenna array 2 through the SMA connector 1 Energy, electromagnetic waves radiated by the microstrip antenna array 2 are emitted through the radome 3 based on the slotted cross metal strip structure.

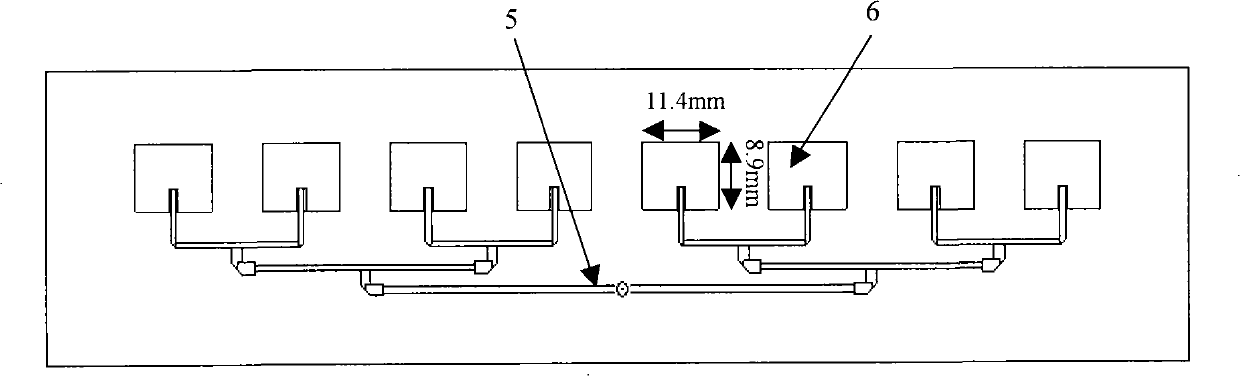

[0027] refer to Figure 4 , the microstrip antenna array is composed of 1×8 8 microstrip patches. The distance from the SMA connector through the microstrip line to each microstrip patch is the same. The impedance of the SMA connector is the standard 50 ohms. In order to match the impedance of the SMA connector with each microstrip patch antenna and achieve th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com