Pointer type safety valve

A safety valve and pointer-type technology, which is applied in the direction of safety valves, balance valves, valve devices, etc., can solve the problems of manpower and time loss, high cost of pressure gauges, and inability to report pressure, etc., and achieves simple structure, low cost, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

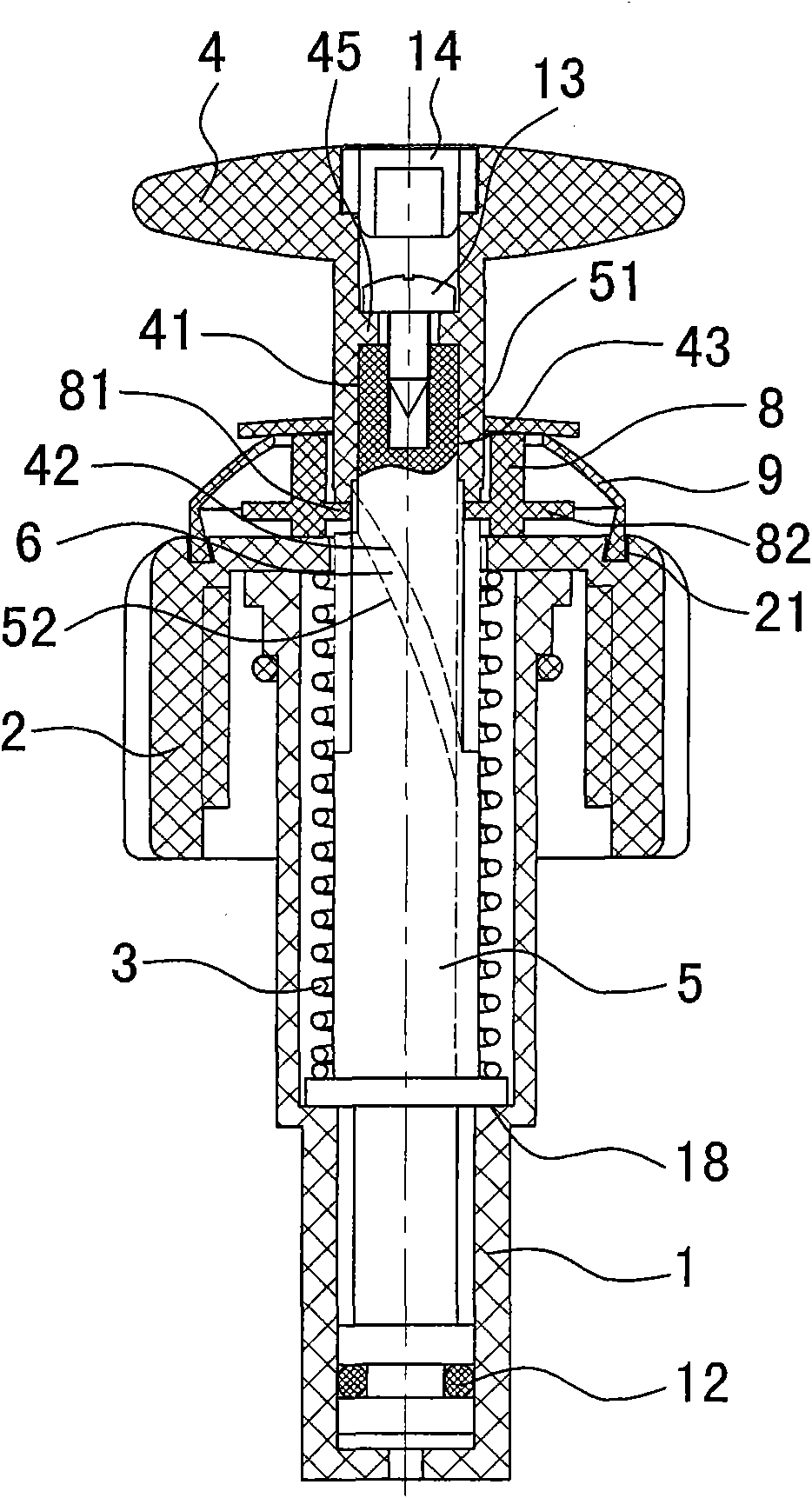

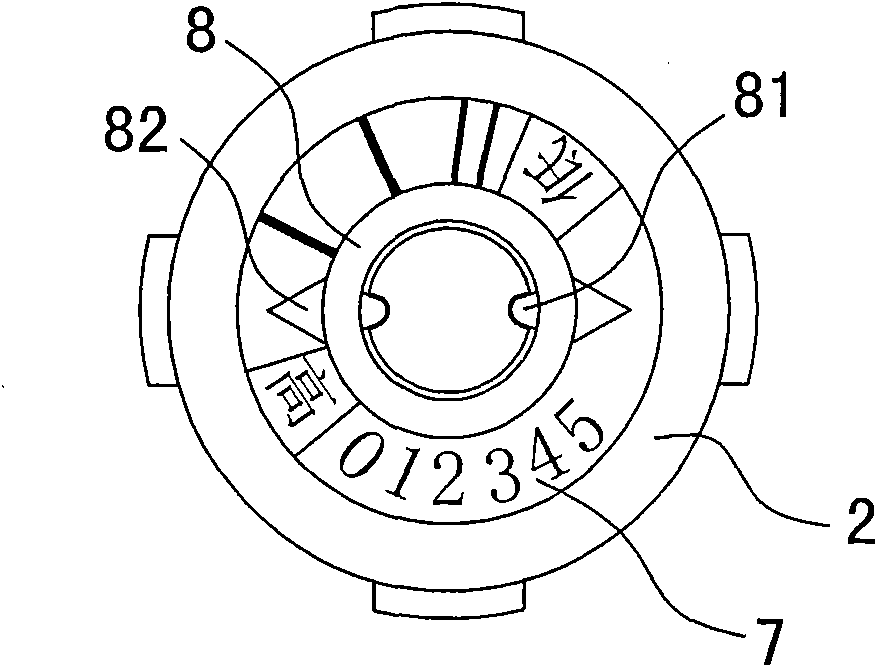

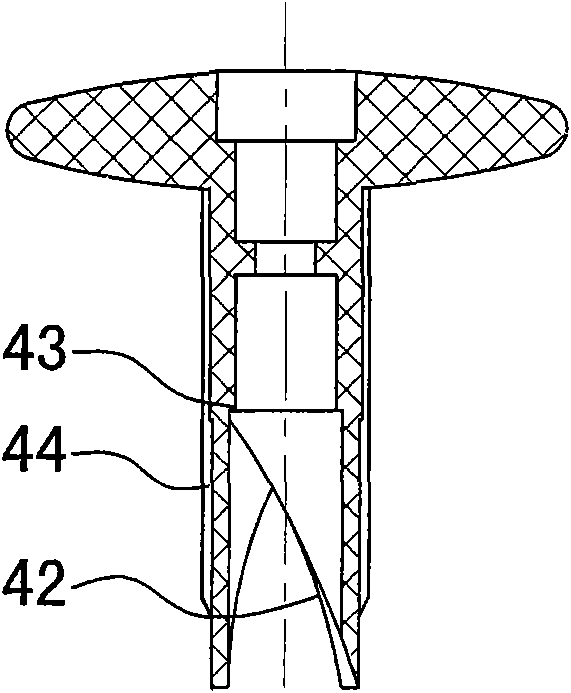

[0013] The invention discloses a pointer safety valve, such as figure 1 As shown, including the valve sleeve 1, the opening of the valve sleeve is sealed by the bonnet 2, the valve stem is installed inside the valve sleeve 1, the valve stem is equipped with a spring 3, the spring withstands the bonnet 2, the upper end of the valve stem passes through the bonnet 2, and its The feature is that the inner wall of the valve sleeve 1 is formed with a step 18, the lower end of the valve stem matches the inner wall of the valve sleeve below the step through the sealing ring 12, the valve stem is formed with a spiral guide groove 6, and the top surface of the valve cap 2 has a pressure scale 7 , the movable ring 8 is arranged on the pressure scale gauge 7, and the movable ring inner wall is shaped on guide rib 81, and the guide rib cooperates with the spiral guide groove 6, and the movable ring outer wall is shaped on pointer 82, and pointer 82 points to pressure scale gauge 7, as fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com