Sliding type damping buffering thrust wheel device

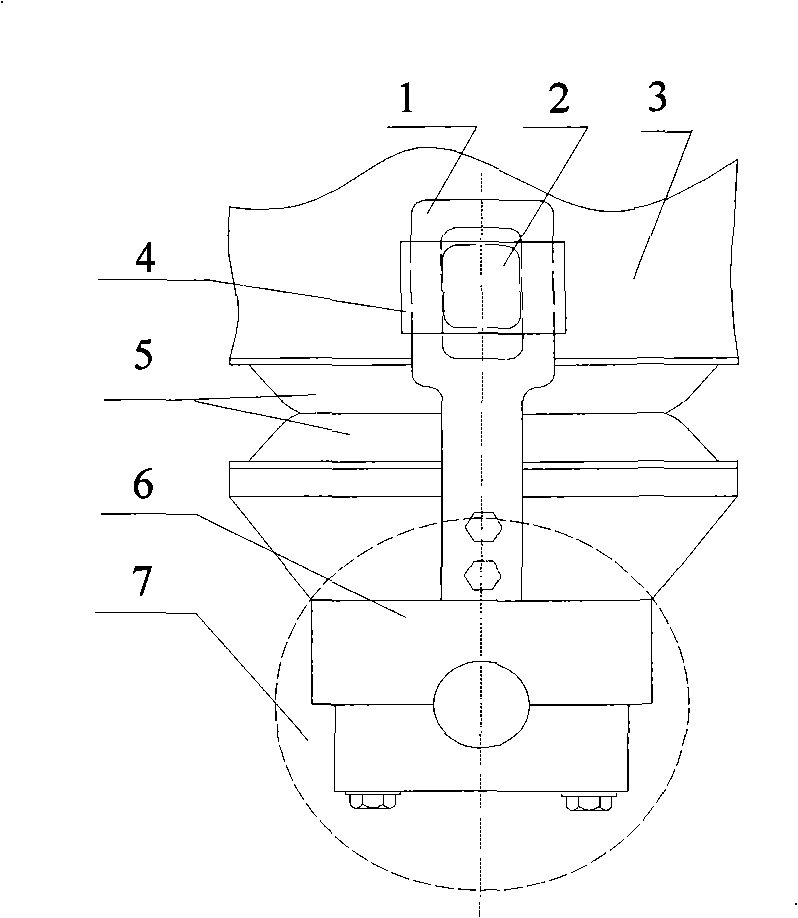

A roller and sliding technology is applied in the field of track roller devices for tracked construction vehicles, which can solve the problems of vibration and impact of the traveling mechanism, the comfort of driving that affects the service life of vehicle components, and track derailment. Impact, improve the productivity of vehicle operation, avoid the effect of track derailment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0099] A 300kW crawler bulldozer has a mass of 50,000kg (excluding the mass of the scarifier), and its working environment temperature is between -40°C and 50°C.

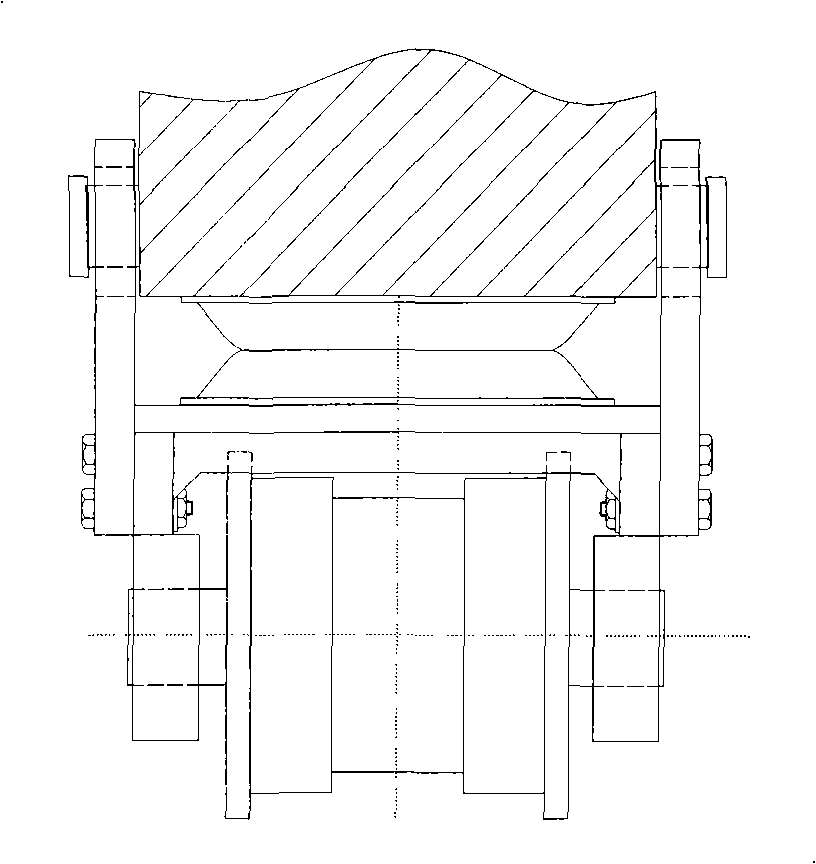

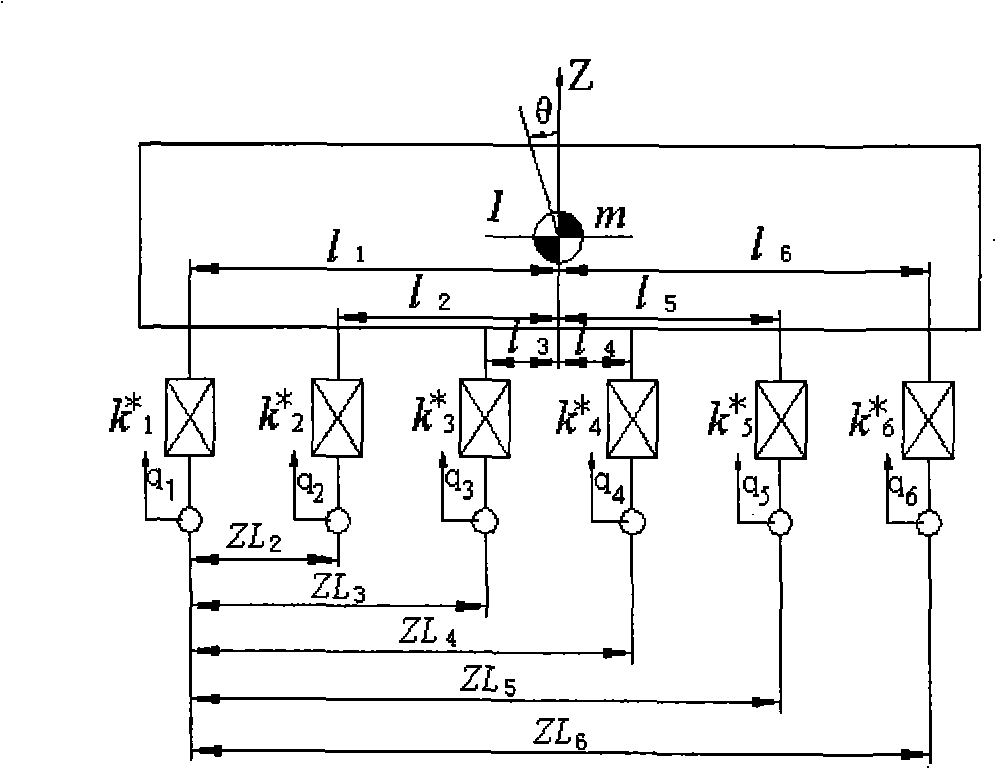

[0100] 1. Design of slider guide rail mechanism

[0101] The upper and lower distances between the fixed slider and the guide rail are determined as follows:

[0102] 1.1. Determination of the vertical distance between the fixed slider and the bottom of the guide rail

[0103] The maximum design load of the track roller device is the working condition that only one pair of track roller devices bear the weight of the whole machine when passing obstacles. Therefore, it can be considered that under the ultimate load, the viscoelastic shock absorber reaches the maximum compression deformation. At this time, the vertical distance between the roller device and the car body is the basis for determining the vertical distance between the fixed slider and the bottom of the guide rail. At this time, the vertical distance bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com