Pipe gas flow crushing device

A technology of airflow crushing and pipeline, which is applied in the field of pipeline airflow crushing device for fly ash, which can solve the problems of high drive motor power and high energy consumption, and achieve the effects of low operating noise, simple system and low investment

Inactive Publication Date: 2009-09-09

HUNAN ELECTRIC POWER POWDERED COAL ASH COMPLEX UTILIZATION DEV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the heavy weight of the ball mill and the metal ball itself, the required driving motor power is also very large, ranging from several hundred to more than one thousand kilowatts, and the energy consumption is extremely high.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

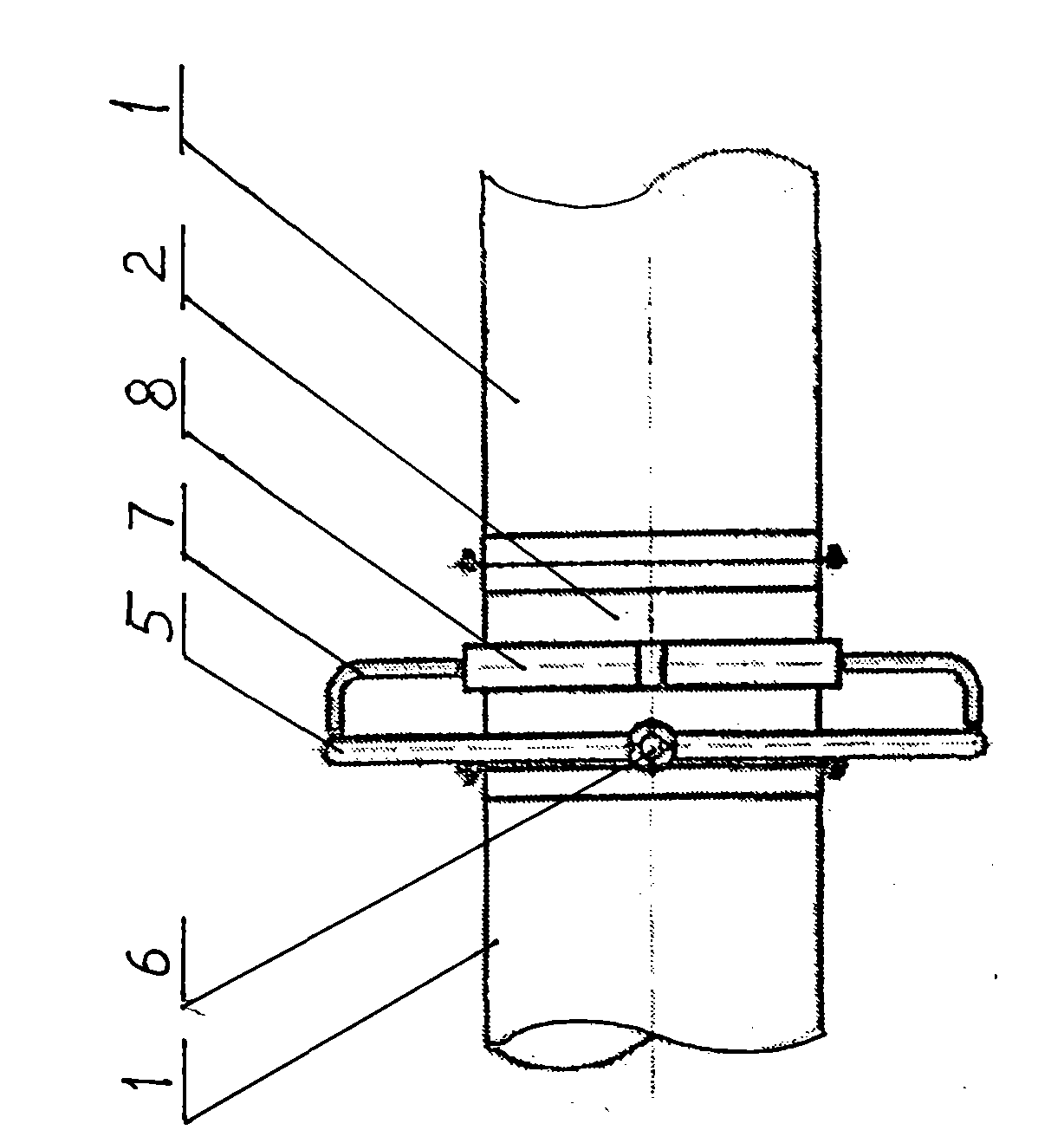

[0037] Referring to the accompanying drawings, this pipeline airflow crushing device is a section of pipeline with a spray gun ring. The ring pipe, the air compressor is connected to the O-ring pipe through the compressed air pipeline, and the O-ring pipe is connected to the nozzles through the radial branch pipes, and the nozzles spray super high-speed or subsonic airflow into the pipe.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A pipe gas flow crushing device is a section of pipe with a spray gun ring, wherein the two ends of the pipe are in sealed joint with fly ash gas flow pipes, the spray gun ring is provided with a plurality of nozzles, the periphery of the pipe is provided with an O-shaped annular pipe, an air compressor is connected and communicated with the O-shaped annular pipe through a compressed air pipe, the O-shaped annular pipe is communicated with the nozzles through radial branch pipes, and the nozzles spray ultra high speed gas flows into the pipes. The device remarkably saves energy, occupies extremely small floor area, and is high in fine powder amount, simplified in process, good in sealing and environment-protection performance, simple in structure, and low in investment and production cost.

Description

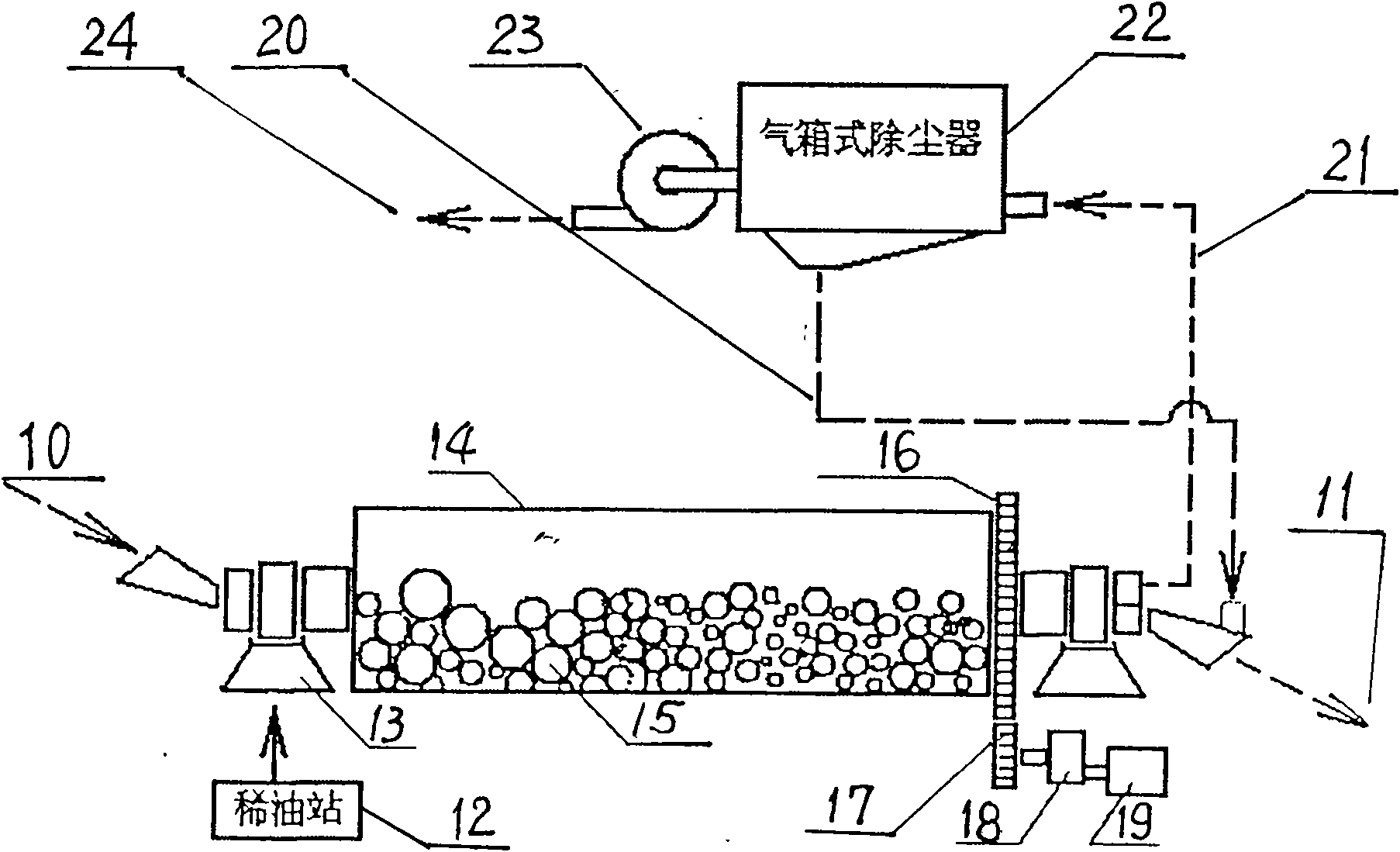

Technical field: [0001] The invention relates to a material crushing device, in particular to a pipeline airflow crushing device for fly ash. Background technique: [0002] The traditional fly ash crushing method is to use a ball mill to grind the fly ash. see Figure 4 The schematic diagram of the ball mill structure is shown. The main body of the ball mill is cylindrical, that is, a rotating cylinder with a diameter of 1 to 3 meters and a length of several meters to more than ten meters. It is hollow and placed horizontally on the bearing bush. When grinding, 50% of the cylinder cavity The space is filled with fly ash and wear-resistant metal balls (several tons to nearly a hundred tons), and an external high-power high-voltage motor is used to drive the cylinder to rotate at a low speed through a reduction box. The impact and the friction between each other realize the fine grinding of fly ash. Because the weight of the ball mill and the metal ball itself is very large,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B02C19/06

Inventor 石峰管国华

Owner HUNAN ELECTRIC POWER POWDERED COAL ASH COMPLEX UTILIZATION DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com