High-low temperature waste water double-channel heat recovery heat pump system

A heat pump system and high temperature wastewater technology, which is applied in the field of heat pump operation system and dual heat recovery heat pump system for high and low temperature wastewater, can solve the problem of inability to recover heat energy from high temperature wastewater, achieve good environmental benefits, reduce system operating costs, and low operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

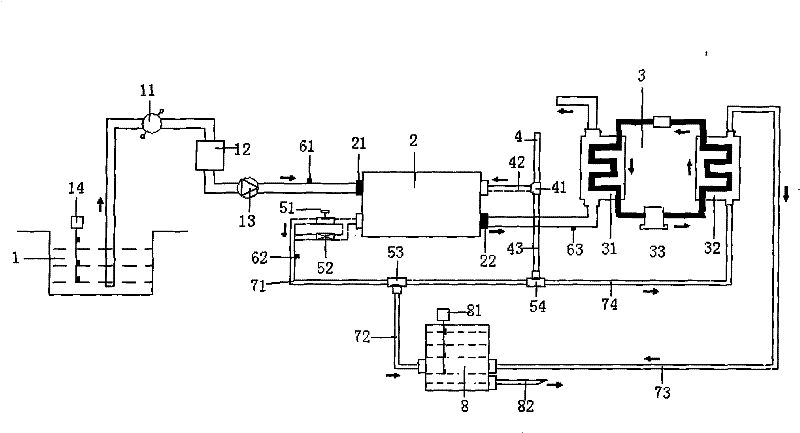

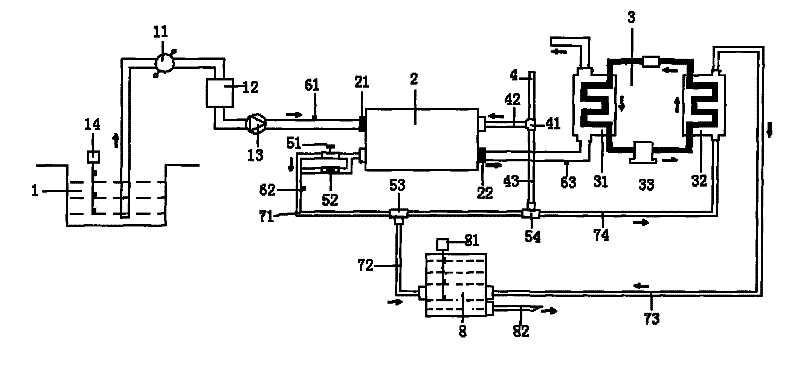

[0014] as the picture shows:

[0015] The waste water hot water single-channel input path of the present invention is:

[0016] The waste water is sent to the heat exchanger 2 through the filter device 11 and the negative pressure tank 12 from the waste water collection tank 1 through the self-priming water pump 13, and the waste water enters from the waste water inlet 21 of the heat exchanger. There is a temperature difference between the inner wall of the device and the outer wall of the heat exchange copper tube where the cold tap water is located, and the waste hot water releases heat, thereby realizing the first input of heat energy. The cooled waste hot water comes out from the heat exchanger outlet 22 and enters through the waste water pipe. To the waste water inlet of the evaporator 31 of the hot water source heat pump 3, heat exchange is carried out in the heat exchange copper tube of the evaporator with the low-temperature refrigerant outside the tube wall, thereby r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com