Aqueous inkjet ink and inkjet recording method

An inkjet recording method and water-based inkjet technology, which can be used in ink, printing, household appliances, etc., and can solve the problems of reduced pigment dispersion stability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, embodiments of the present invention will be specifically described.

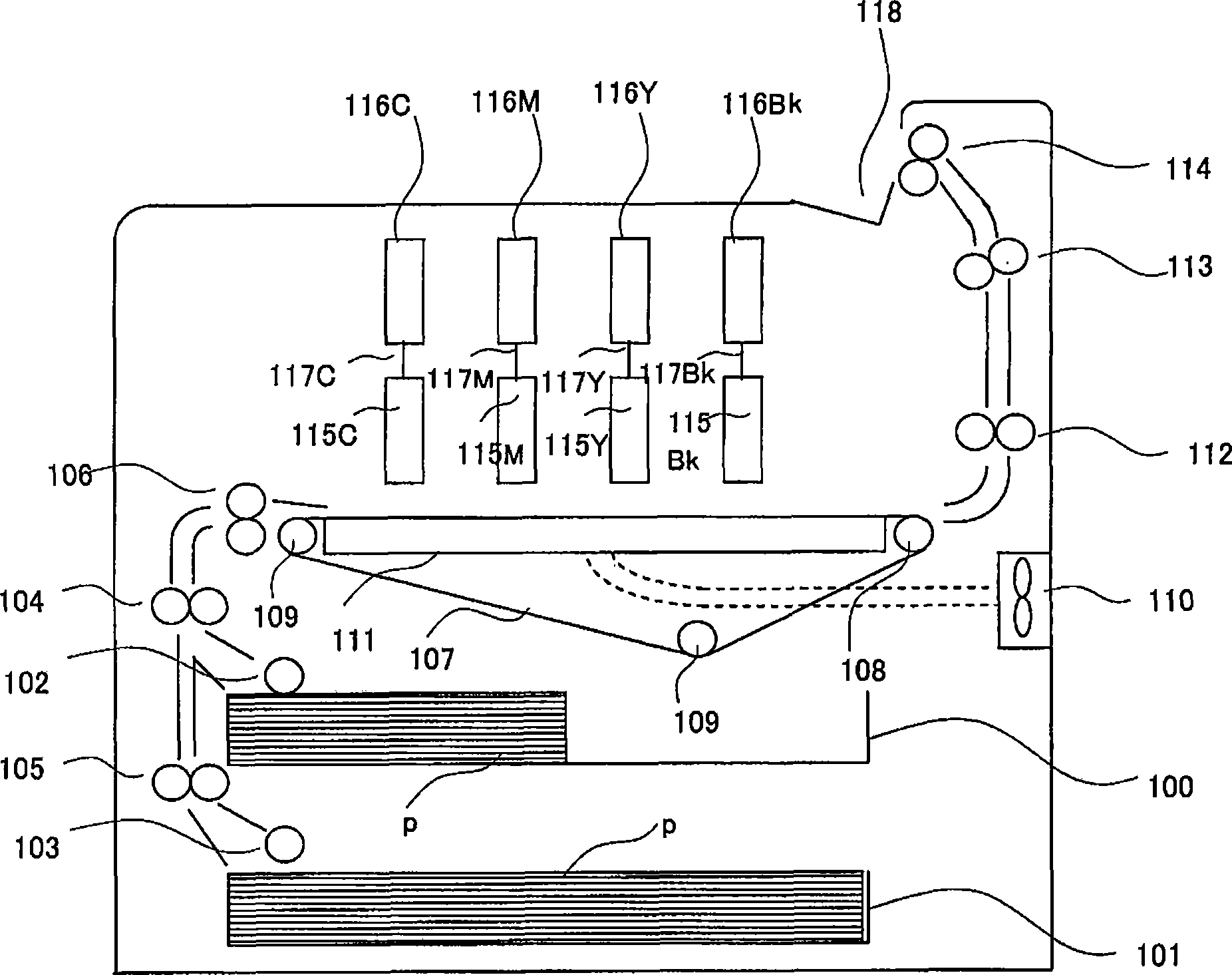

[0019] figure 1 It is a cross-sectional view of a recording apparatus used in the inkjet recording method according to the embodiment of the present invention. The paper cassette 100 and the paper cassette 101 are used for storing sheets p of different sizes. The paper feed roller 102 or the paper feed roller 103 takes out the paper p corresponding to the selected paper size from the paper cassette 100 or the paper cassette 101 , and conveys it to the pair of conveying rollers 104 and 105 and the pair of registration rollers 106 .

[0020] Tension is imparted to the conveyor belt 107 by the driving roller 108 and the two driven rollers 109 . The surface of the conveyor belt 107 is provided with holes at predetermined intervals, and a negative pressure chamber 111 connected to a fan 110 is provided in order to attract the paper p to the conveyor belt 107 inside the conveyor belt 107 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com