Foamed high-resilience polyurethane wave-absorbing material and preparation method thereof

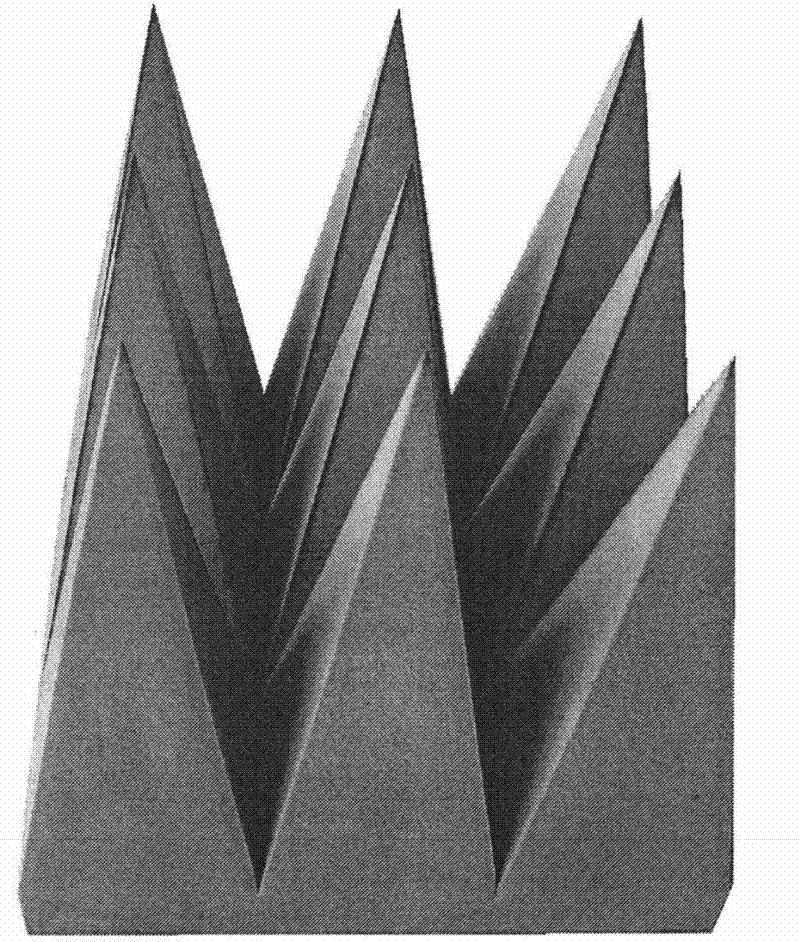

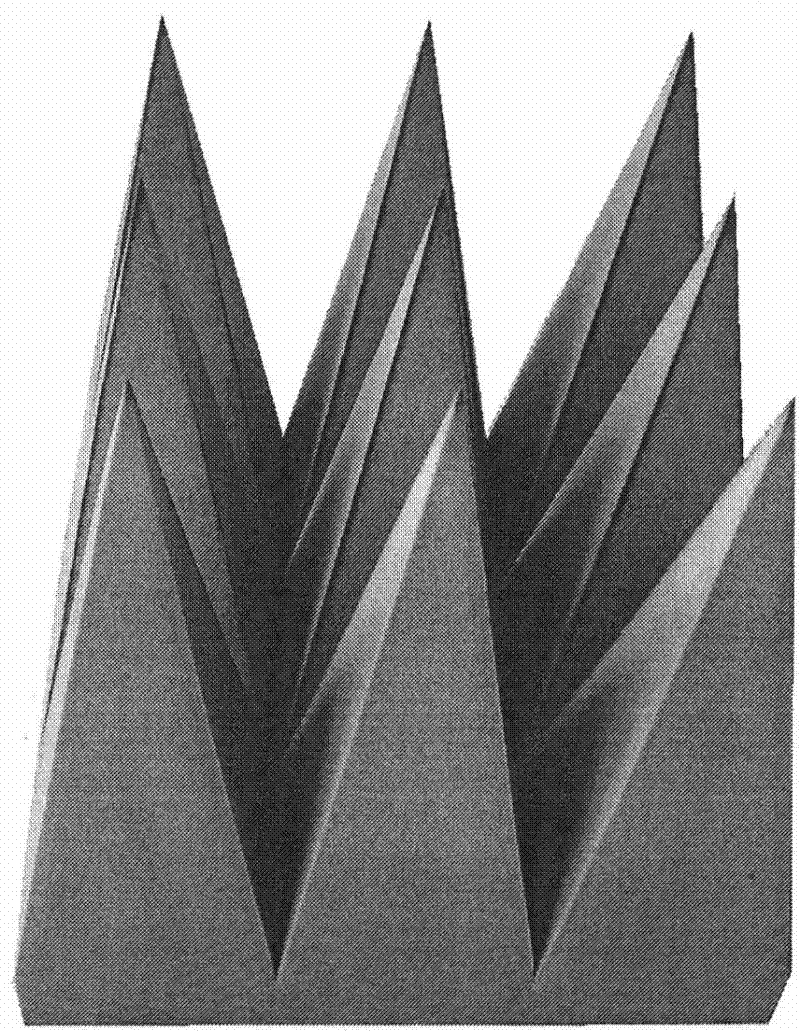

A wave-absorbing material and high-resilience technology, which is applied in the field of foamed high-resilience polyurethane wave-absorbing material and its preparation, can solve the problems of large size tolerance of finished products, uneven distribution of absorbents and flame retardants, and overall performance impact, etc. problem, to achieve the effect of accurate and consistent bottom surface size, beautiful visual effect, and regular material shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] The specific production process and raw material configuration method of this product are as follows:

[0028] The raw materials are divided into A component and B component.

[0029] Component A is 100% polyether polyol with a molecular weight of 4000-6000 as the main material, and water, surfactant (silicone oil), crosslinking agent (diethanolamine or triethanolamine), organic tertiary amine catalyst as auxiliary materials .The proportion of auxiliary materials is 4%, 1%, 1.8%, 1.5% in order. Put the main materials and auxiliary materials into the mixing tank, mix and stir for 2 to 3 hours, and release them for later use. In order to improve the flame retardant performance of the product, add Add 15% melamine and 15-20% PCF or A300TBLS liquid flame retardant to polyether polyol, and add conductive carbon fiber and stir together.

[0030] B component is 4,4'-diphenylmethane diisocyanate

[0031] Put the prepared components A and B into the two material tanks of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com