Novel membrane electrode component available for fuel cell, preparation method and application thereof

A membrane electrode assembly, fuel cell membrane technology, applied in fuel cell parts, fuel cells, battery electrodes, etc., can solve problems such as reducing the utilization rate of Pt, and achieve the effect of improving the utilization rate, uniform structure, and improving the reaction interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

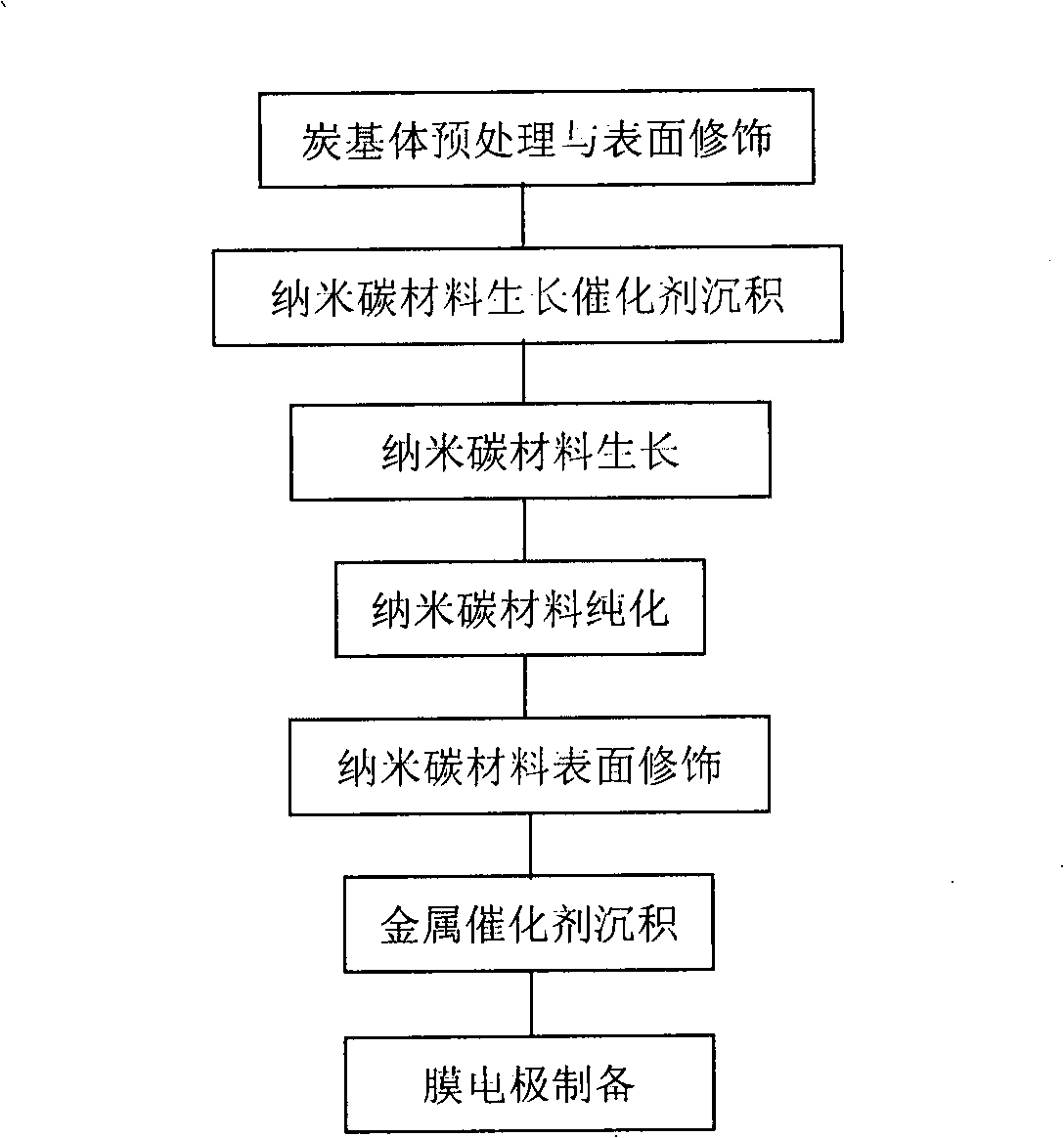

[0037] Embodiment 1: as figure 1 As shown, the first is the pretreatment and surface modification of the carbon substrate. The purpose of pretreatment is to modify the surface of the carbon substrate and adjust the hydrophilicity, so as to facilitate the growth of nano-carbon materials or the deposition of catalyst precursors. It can be treated by acid treatment, alkali treatment, or air treatment. Take 5×5cm 2 Carbon paper (Toray-090, Toray Corporation of Japan), immersed in 3mol / l HNO 3 Soak in the solution for 48 hours at 40°C. Wash with deionized water until the pH of the washing solution is 7. It is then filtered and dried to obtain figure 2 The pretreated and surface-modified carbon substrates are shown.

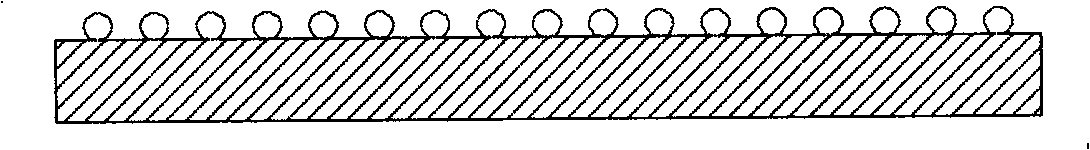

[0038] like figure 1 As shown, the catalysts required for the growth of carbon nanomaterials were supported on the pretreated and surface-modified carbon substrates. The main purpose of depositing catalysts is to better control the structure and properties of ...

Embodiment 2

[0045] Take a piece with an area of 5×5cm 2 Carbon cloth, at 60°C, 2mol / l H 2 SO 4 Soak in the solution for 48h. Wash with deionized water until the pH of the washing solution is 7. Then filter and dry to obtain the desired carbon matrix.

[0046] The specific preparation process of the membrane module is the same as that of Example 1 except for the differences in the carbon substrate and the treatment method.

Embodiment 3

[0048] Take a piece with an area of 5×5cm 2 Carbon paper, at 60°C, 2mol / l H 2 SO 4 Soak in the solution for 48h. Wash with deionized water until the pH of the washing solution is 7. Then filter and dry to obtain the desired carbon matrix.

[0049] Get the above treated carbon paper soaked to 3mol / l Fe(NO 3 ) 2 In the solution for 18h, after drying, put it into a quartz boat and place it in the middle of the quartz reactor, and use H 2 / Ar (50% / 50%, the total flow rate is 80ml / min) atmosphere to reduce the catalyst at 500° C. for 8 hours to obtain a carbon matrix-carbon nanotube composite.

[0050] The prepared carbon matrix-carbon nanotube electrocatalyst was heated to 50-60° C. in 2 mol / l HCl solution, and kept stirring for 4 hours, and then washed with ultrapure water until the pH value was equal to 7. Finally filter washed and dried overnight at 120°C.

[0051] Take the above-mentioned purified carbon matrix-carbon nanotube complex and put it in 2mol / l HNO at a ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com