Quenching unit of aluminum alloy plate and method thereof

A technology of aluminum alloy plate and quenching device, which is applied in the field of quenching device and quenching treatment of aluminum alloy plate, can solve the problems of plate residual stress, poor performance uniformity and stability, large quenching residual stress, etc., and achieve reduction of residual stress , Increase the depth of hardening and reduce the effect of quenching residual stress

Active Publication Date: 2011-01-05

CENT SOUTH UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When the aluminum alloy plate is quenched and cooled, the difference in cooling rate from the surface to the center in the thickness direction makes the performance uniformity and stability in the thickness direction worse on the one hand, and on the other hand, it will generate a large quenching residual stress in the plate.

Therefore, the quenching of aluminum alloy plates must not only increase the depth of hardening, but also reduce the residual stress after quenching. The requirements of these two aspects are often contradictory. For example, putting aluminum alloy materials or components into a cooling medium with high surface heat exchange efficiency Quenching in the pool or quenching by spraying cooling medium on the surface of the aluminum alloy material, etc., although it helps to increase the hardening depth of the aluminum alloy plate, it will cause a large residual stress in the plate

The existing quenching technology of aluminum alloy plate can not only improve the cooling rate of the center of the aluminum alloy plate, but also minimize the difference of cooling rate between the surface of the plate and the center of the thickness, and improve the hardenability of the aluminum alloy plate by controlling the surface heat transfer characteristics of the aluminum alloy plate. , and reduce the technical scheme of residual stress, the present invention has established a quenching device and method that not only improves the hardening depth of the aluminum alloy plate, but also reduces the quenching residual stress on the basis of studying the surface heat transfer law of the aluminum alloy material.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

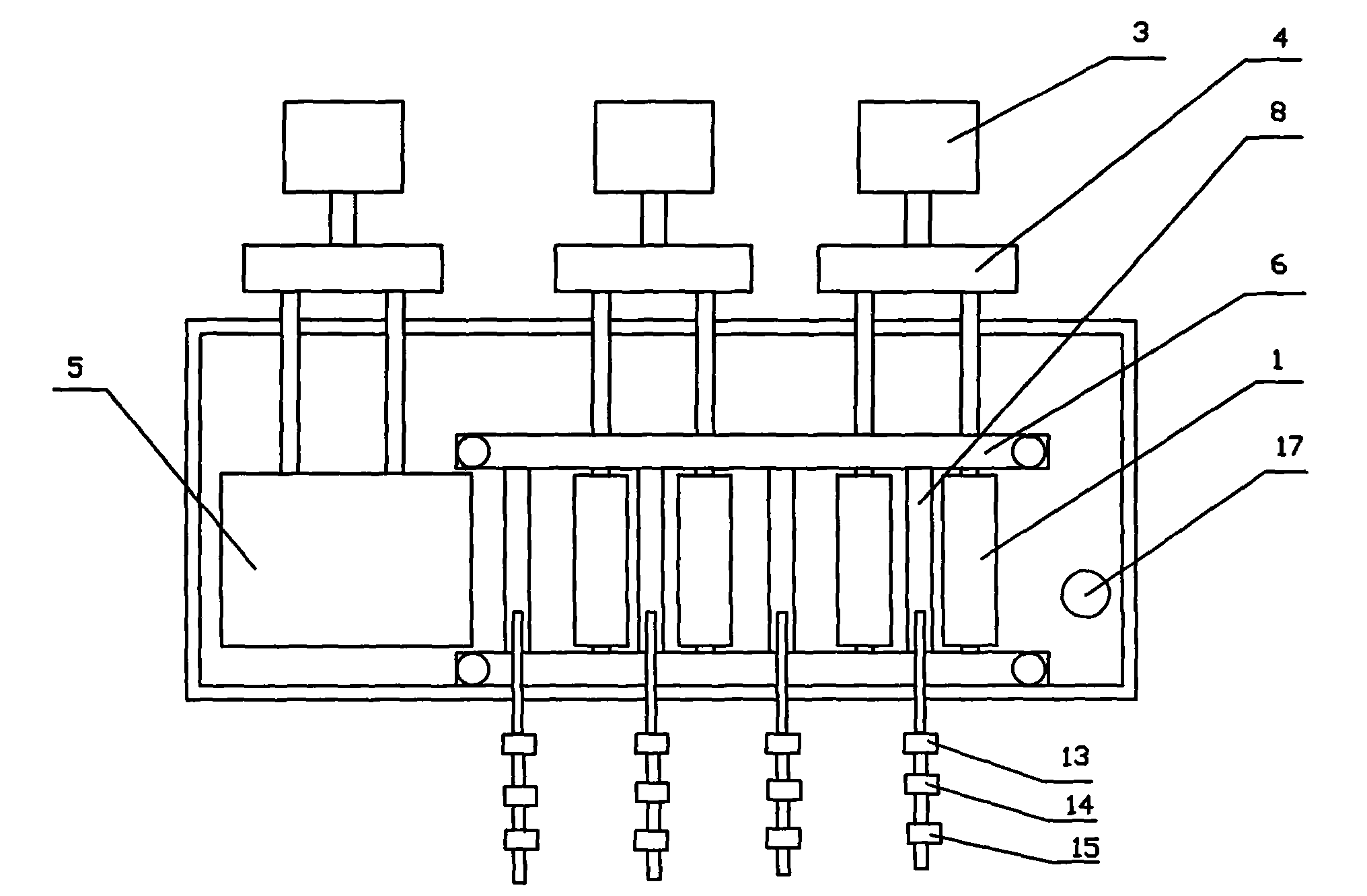

The invention discloses a quenching unit of an aluminum alloy plate. The quenching unit comprises a roll table, an attemperator, an upper bracket, a lower bracket and a nozzle line, the roll table consists of a plurality of rollers which are arranged in parallel and driven by a motor and a driving unit; the attemperator is arranged at one end of the roll table; the upper bracket and the lower bracket are arranged on the upper part and lower part of the roll table respectively; the nozzle line is arranged on tracks of the upper bracket and the lower bracket and connected with a pressure deviceby a pipeline which is equipped with a switch valve, a flow meter and a pressure meter. A method for quenching the aluminum alloy plate with the quenching unit comprises the following steps: firstly sending the aluminum alloy plate to the attemperator at one end of the roll table, then regulating position of the nozzle line, flux density and pressure of a cooling medium in nozzles on the nozzle line to allow the aluminum alloy plate to run through the nozzle line on the roll table successively. The quenching unit and the method has the advantages of simple and reasonable structure and convenient operation and application, pressure, flow and spray angle of the spray medium can be dynamically regulated at real time according to size of the aluminum alloy plate, thus effectively enhancing quenching depth of the aluminum alloy plate, and reducing residual quenching stress; and the quenching unit and the method are applicable to industrialized production.

Description

Quenching device and method for aluminum alloy plate Technical field The invention relates to the quenching treatment of heat-treatable and strengthened aluminum alloy plates, in particular to a quenching device and method for aluminum alloy plates, and belongs to the technical field of thermal processing of non-ferrous metal materials. Background technique When the aluminum alloy plate is quenched and cooled, the difference in the cooling rate from the surface to the center in the thickness direction on the one hand makes the performance uniformity and stability in the thickness direction worse, and on the other hand, it will produce a larger quenching residual stress in the plate. Therefore, the quenching of aluminum alloy plates not only needs to increase the depth of quenching, but also reduce the residual stress after quenching. These two requirements are often contradictory, such as placing aluminum alloy materials or components into a cooling medium with high surface hea...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C21D1/667C21D1/60C21D11/00C22F1/04

Inventor 张新明邓运来张勇熊创贤万里曹盛强刘胜胆张劲

Owner CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com