All-fiber crankshaft bending upsetting multi-crank indexing positioning device for large-sized ships and application method thereof

An indexing positioning and full-fiber technology, applied in the field of forging, can solve the problem of large positioning error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

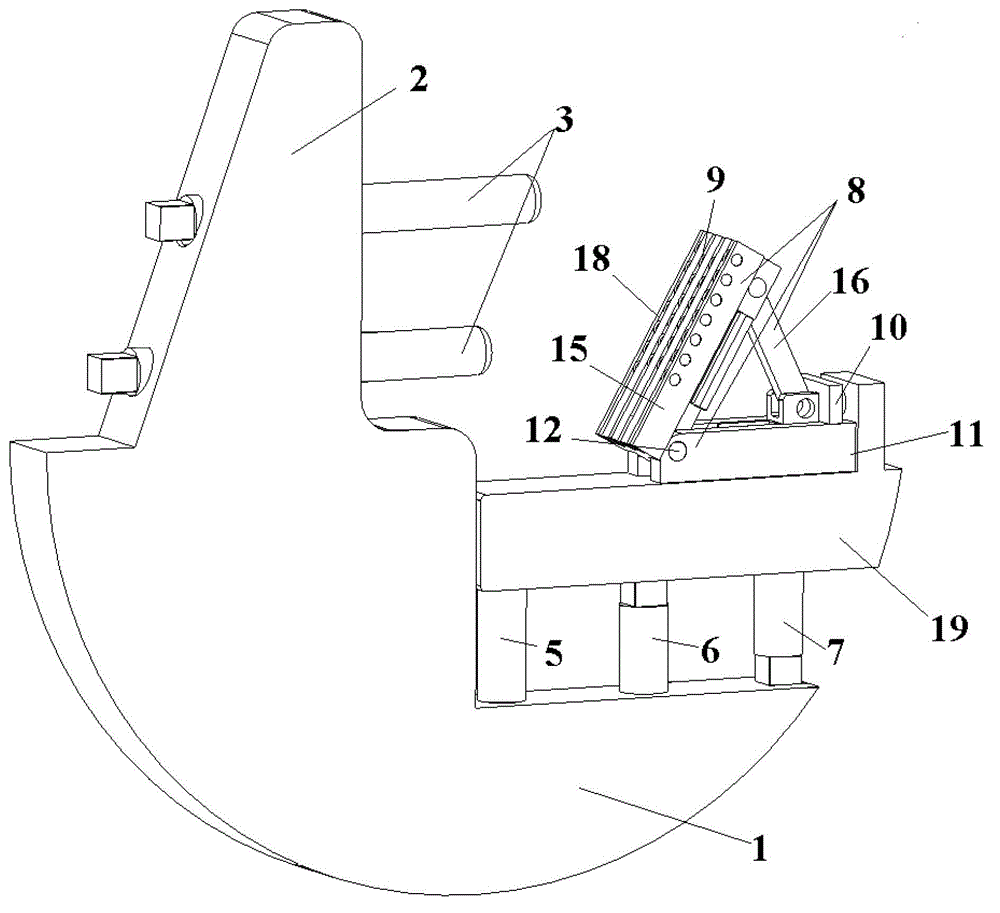

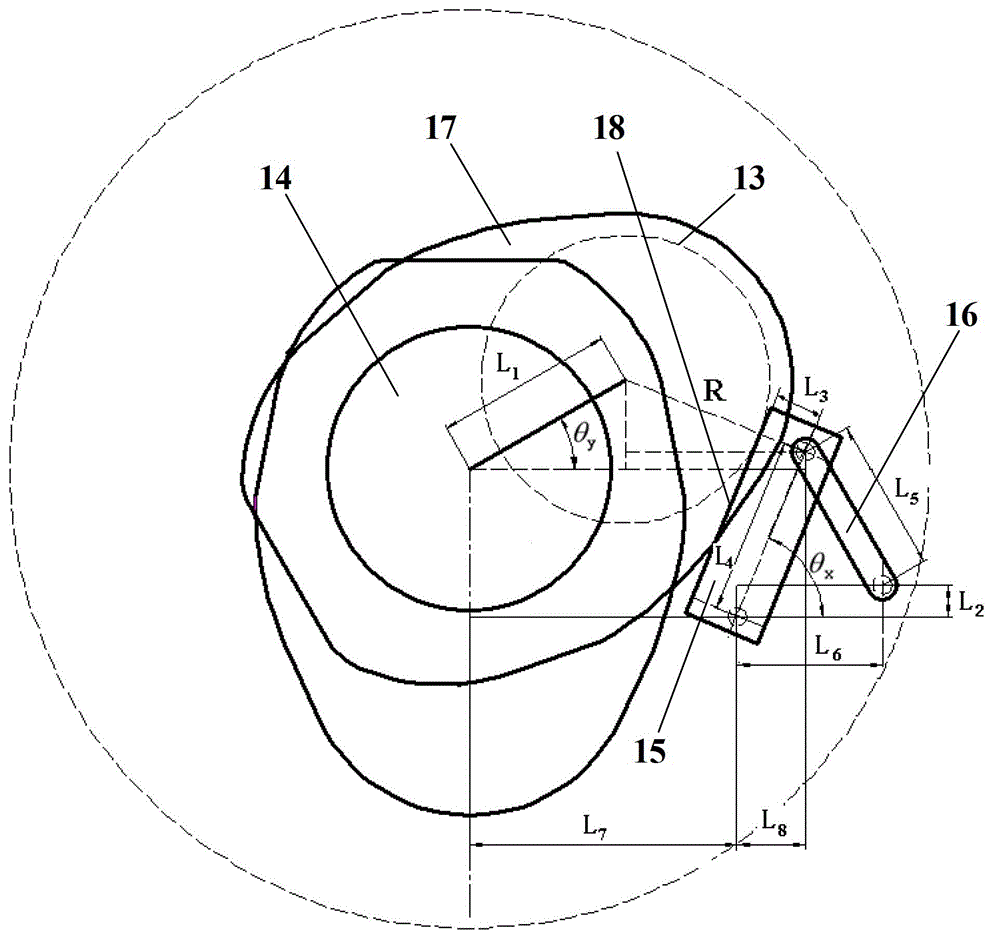

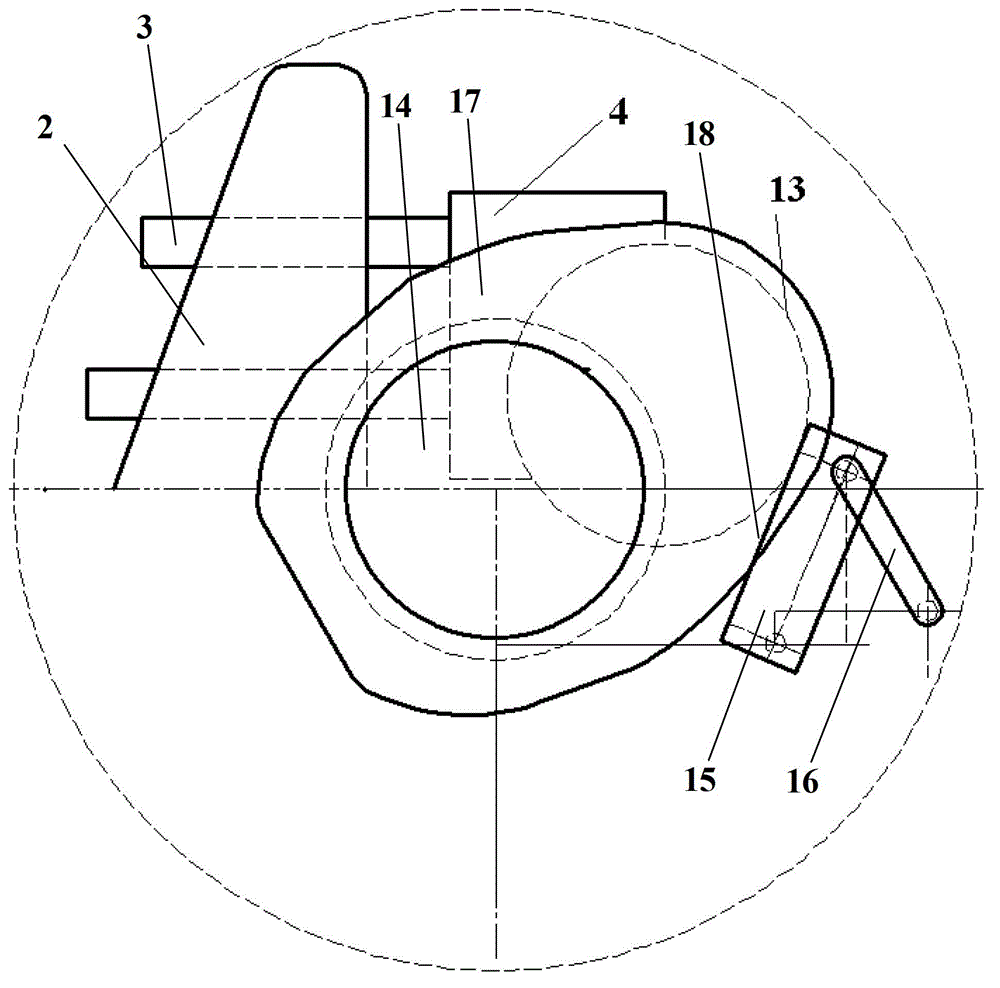

[0082] This embodiment is applied to the bending and upsetting production site of a certain type of large-scale full-fiber crankshaft product in a certain factory. The billet is made of 42CrMo4 steel and weighs 3.5 tons. The part of the billet participating in the deformation is heated to 1180°C. The bending and upsetting process is carried out on a 6000-ton TR method special press. After the crankshaft blank is hoisted and adjusted, the positional relationship between the positioning throw and the positioning device is as follows: image 3 As shown, the movable block pad is locked between the positioning turn connecting rod 13 and the locking screw 3. During the bending and upsetting process, the maximum indexing deviation of the crankshaft due to the radius measurement error of the positioning crutch connecting rod 13 and the forging error of the crankshaft main shaft 14-location crutch connecting rod 13 center distance is 1°, and the maximum indexing deviation between any t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com