Titanium ore acidolysis method through sulfuric acid process

A sulfuric acid method and acid hydrolysis technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of inconvenient pumping of premixed slurry, affecting the acid hydrolysis rate during the acid hydrolysis process, and complex process, and achieve the improvement of premixed slurry. The effect of mixing effect, reducing energy consumption and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

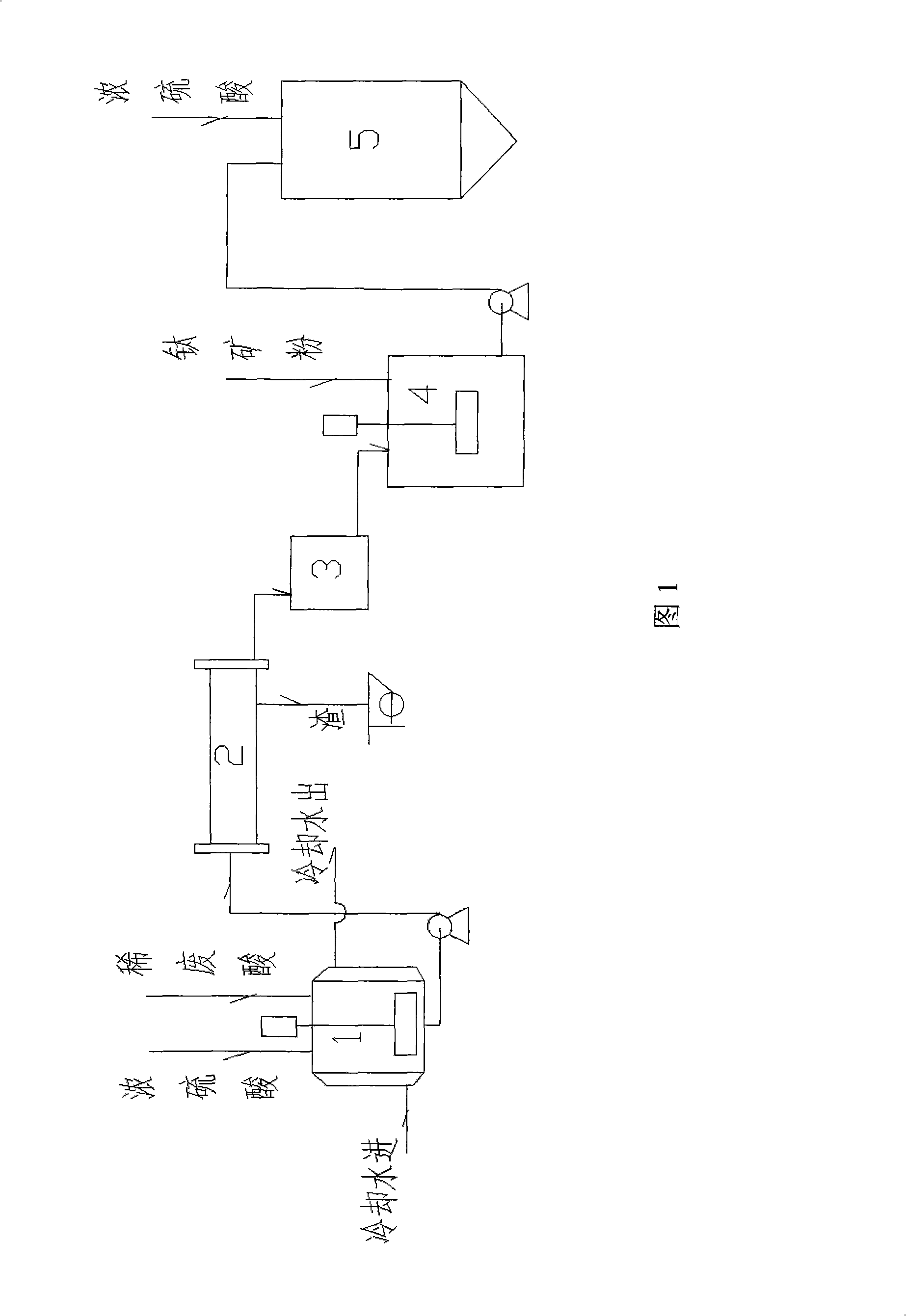

Image

Examples

Embodiment 1

[0027] 1) Add 24.6% dilute waste acid and 98% concentrated sulfuric acid produced by the sulfuric acid process titanium dioxide into the cooling crystallizer 1 at a ratio of 1:0.707. After mixing, the concentration is 55%. Fully cool the mixed acid To 53°C, continue aging in the crystallizer 1 for 2 hours to precipitate impurities. Then, after the solid impurities are removed with the filter press 2, the clear liquid is loaded into the concentrated waste acid tank 3.

[0028] 2) The acid ore ratio determined according to the characteristics of the titanium concentrate used and the initial concentration of the acid hydrolysis reaction are 1.55 and 84% respectively, and the amount of waste acid added is calculated to be 18 tons. Therefore, put 18 tons of concentrated waste acid from the concentrated waste acid tank 3 into the premix tank 4, start the premix tank agitator, add 30 tons of ground 47% titanium concentrate, and mix for 10 minutes.

[0029]3) Put the mixed slurry into...

Embodiment 2

[0033] 1) Put the concentrated and impurity-removed titanium white waste acid from the sulfuric acid process into the concentrated waste acid tank 3 with a concentration of 62% and a temperature of 55°C.

[0034] 2) The acid ore ratio determined according to the characteristics of the titanium concentrate used and the initial concentration of the acid hydrolysis reaction are 1.57 and 86% respectively, and the amount of waste acid added is calculated to be 18.3 tons. Therefore, put 18.3 tons of concentrated waste acid from the concentrated waste acid tank 3 into the premix tank 4, start the premix tank agitator, add 30 tons of ground 46.5% titanium concentrate, and mix for 10 minutes.

[0035] 3) pump the mixed slurry from the premixing tank 4 into the acidolysis pot 5, feed compressed air into the bottom of the acidolysis pot to stir, add 36.5 tons of 98% concentrated sulfuric acid according to the calculation results, and trigger the main reaction.

[0036] 4) After the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com