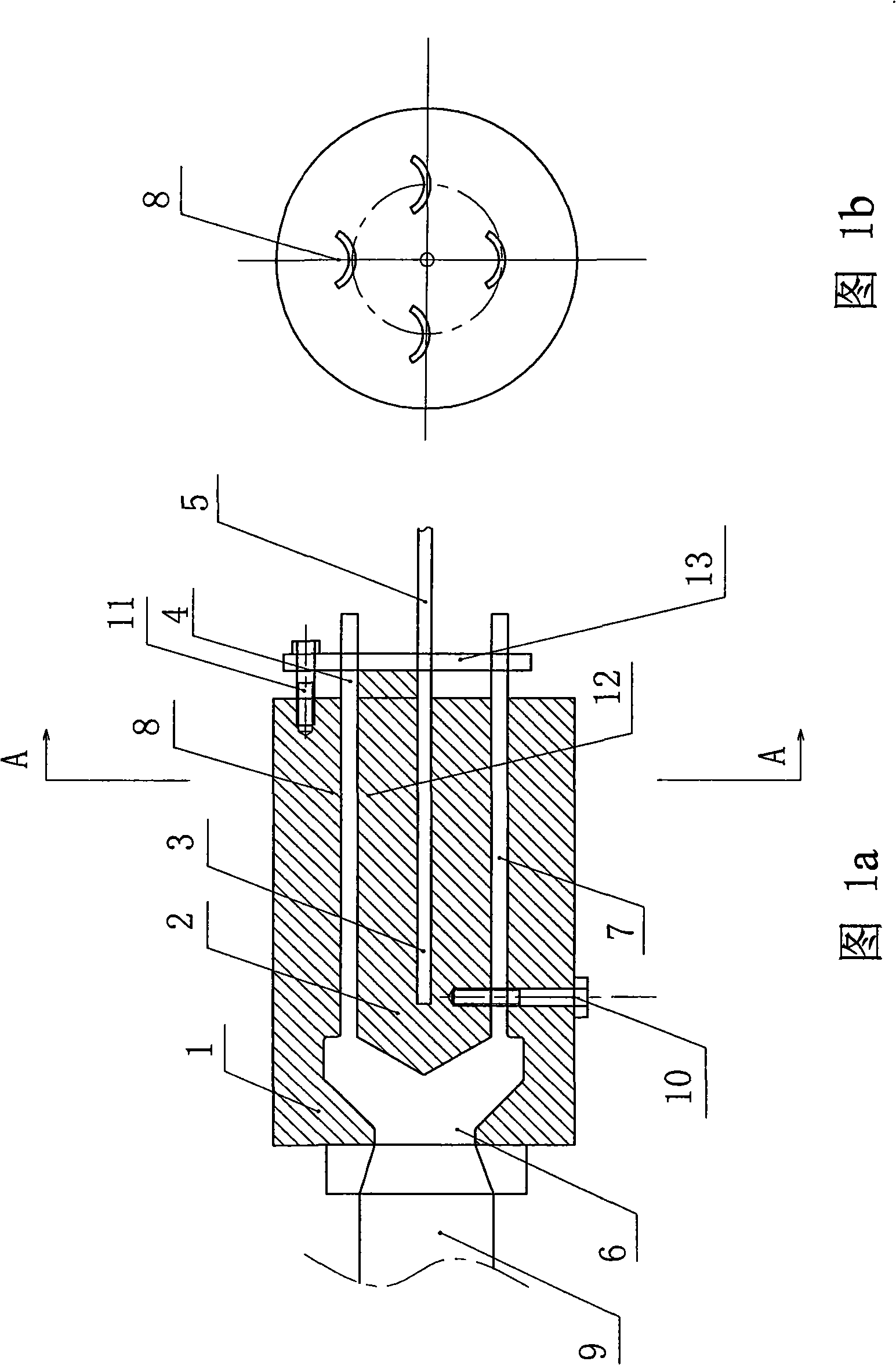

Flow channel device capable of extruding out a plurality of magnets once for extruding machine and preparation method using same

An extrusion molding machine and flow channel technology, applied in the direction of magnetism of inorganic materials, can solve the problems of uneven magnet density, uneven density, component segregation, etc., easy to achieve size and shape tolerance, good central symmetry, density easy consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] The NdFeB magnetic powder used in the magnet accounts for 84 wt%, the ferrite magnetic powder accounts for 1 wt%, and the binder PPS accounts for 15 wt%. After uniform mixing and kneading, it is made into kneading powder. Using the extrusion flow channel device of the present invention, under the conditions of temperature, extrusion speed and extrusion pressure of each flow channel of the extrusion device shown in Table 2, one-time extrusion molding was performed to obtain multiple pieces of magnets.

[0092] Table 2

[0093] parts

Main hot runner 6

Sub-hot runner 7 front

(near main road)

Sub-hot runner 7 rear

(near exit)

Formed

magnet 4

temperature(°C)

310~320

290~300

250~260

≤135

Extrusion speed(mm / s)

3~4

5~6

5~6

5~6

Extrusion pressure (MPa)

≥10

≥8

≥7

-

[0094] The texture of each point of the obtained tile-shape...

Embodiment 2

[0097] The NdFeB magnetic powder used in the magnet accounts for 96 wt% of the total weight, and the polyamide resin accounts for 4 wt% of the total weight. After uniform mixing and kneading, it is made into kneading powder. Using the extrusion flow channel device of the present invention, under the conditions of temperature, extrusion speed and extrusion pressure of each flow channel of the extrusion device shown in Table 3, one-time extrusion molding was performed to obtain multiple pieces of magnets.

[0098] table 3

[0099] parts

Main hot runner 6

Sub-hot runner 7 front

(near main road)

Sub-hot runner 7 rear

(near exit)

Formed

magnet 4

temperature(°C)

240~243

220~230

135~145

≤135

Extrusion speed(mm / s)

2~3

4~5

4~5

4~5

Extrusion pressure (MPa)

≥10

≥9

≥6

-

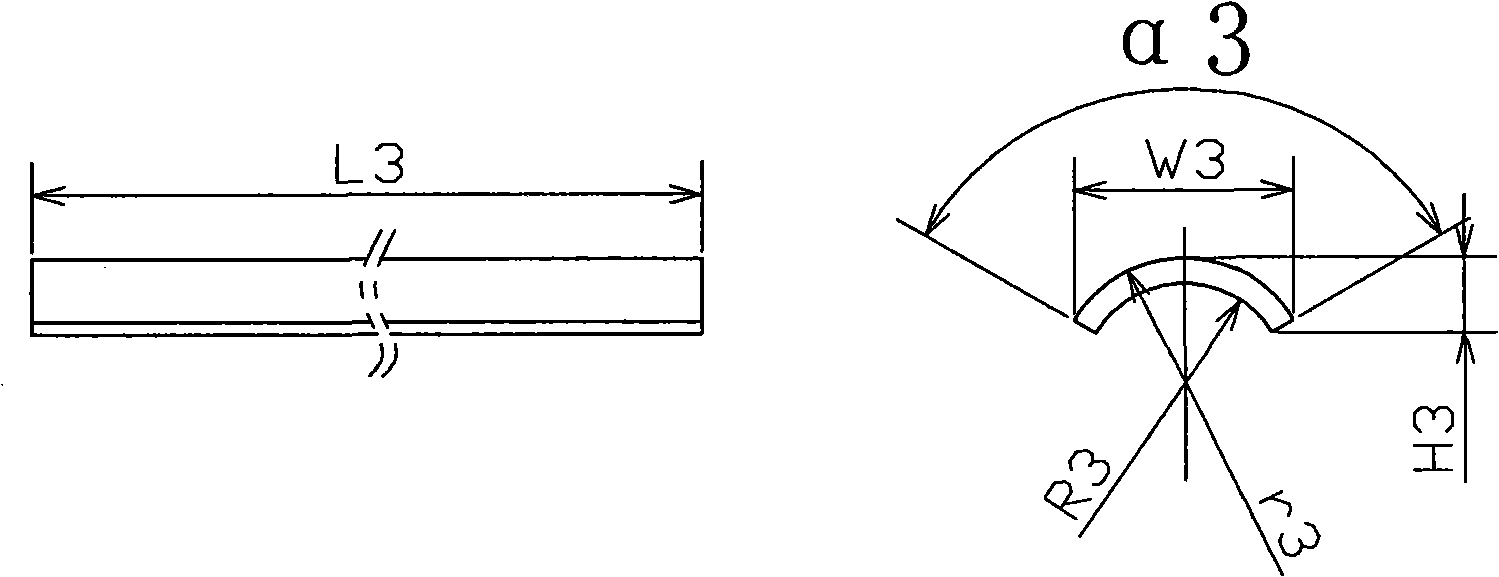

[0100] The texture of each point of the obtained fan-shaped long bar magnet is un...

Embodiment 3

[0103] The NdFeB magnetic powder used in the magnet accounts for 22 wt%, the ferrite magnetic powder accounts for 70 wt%, and the polyamide resin accounts for 8.0 wt%. After uniform mixing and kneading, it is made into kneading powder. Using the extrusion flow channel device of the present invention, under the conditions of the temperature, extrusion speed and extrusion pressure of each flow channel of the extrusion device shown in Table 4, one-time extrusion molding was performed to obtain multiple pieces of magnets.

[0104] Table 4

[0105] parts

[0106] The texture of each point of the obtained ring-shaped magnet is uniform, so the magnetic performance is very uniform, and the size meets the requirements of the drawing. The obtained ring-shaped magnet is as follows Figure 5 As mentioned above, wherein, the outer diameter φ51=17.30±0.05mm, the inner diameter φ52=15.30±0.05mm, the roundness of the outer circular surface is 0.025mm, the coaxiality of the outer ci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| magnetic energy product | aaaaa | aaaaa |

| magnetism | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com