Method of fabricating piezoelectric vibrating piece, wafer, apparatus having the piezoelectric vibrating piece

一种压电振动片、晶圆的技术,应用在压电/电致伸缩器件的制造/组装、用于压电器件或电致伸缩器件的材料选择、压电器件/电致伸缩器件等方向,能够解决维护性能退化等问题,达到减少数量、实现维护性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example 1

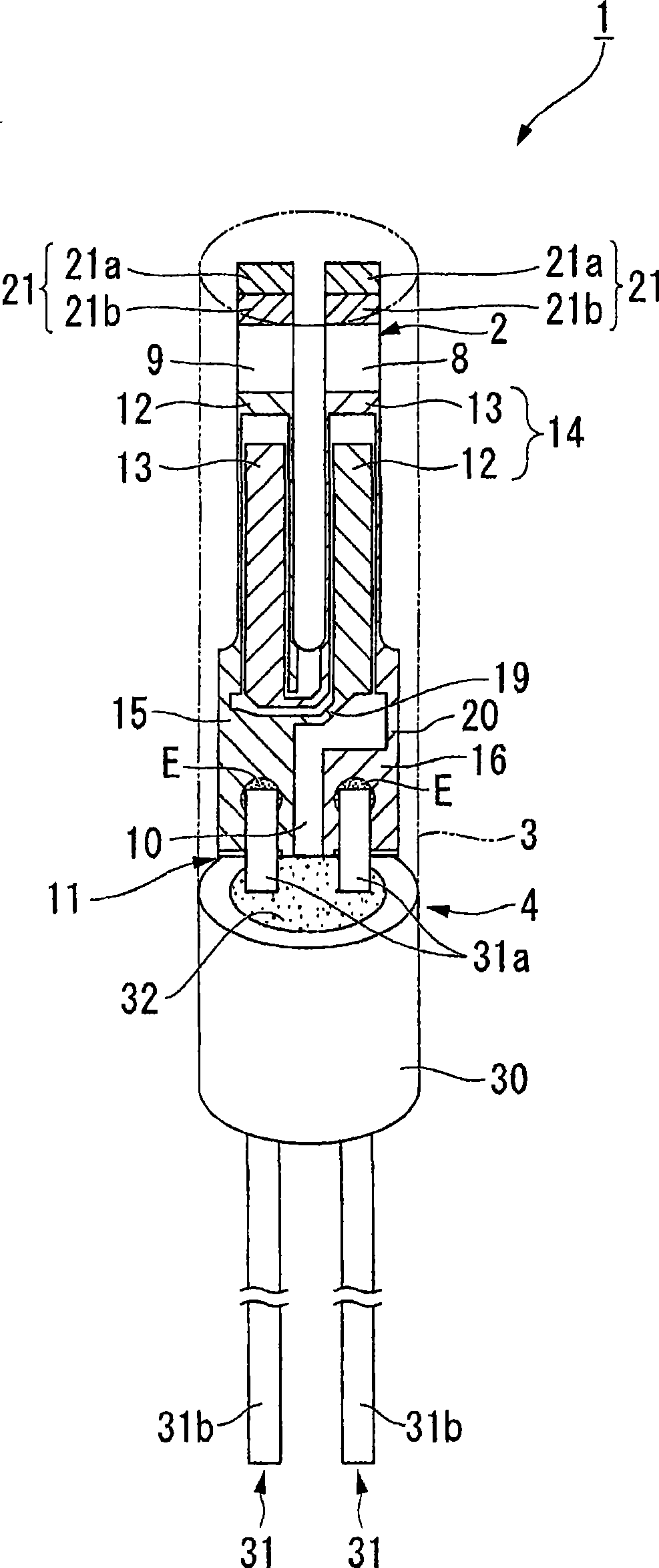

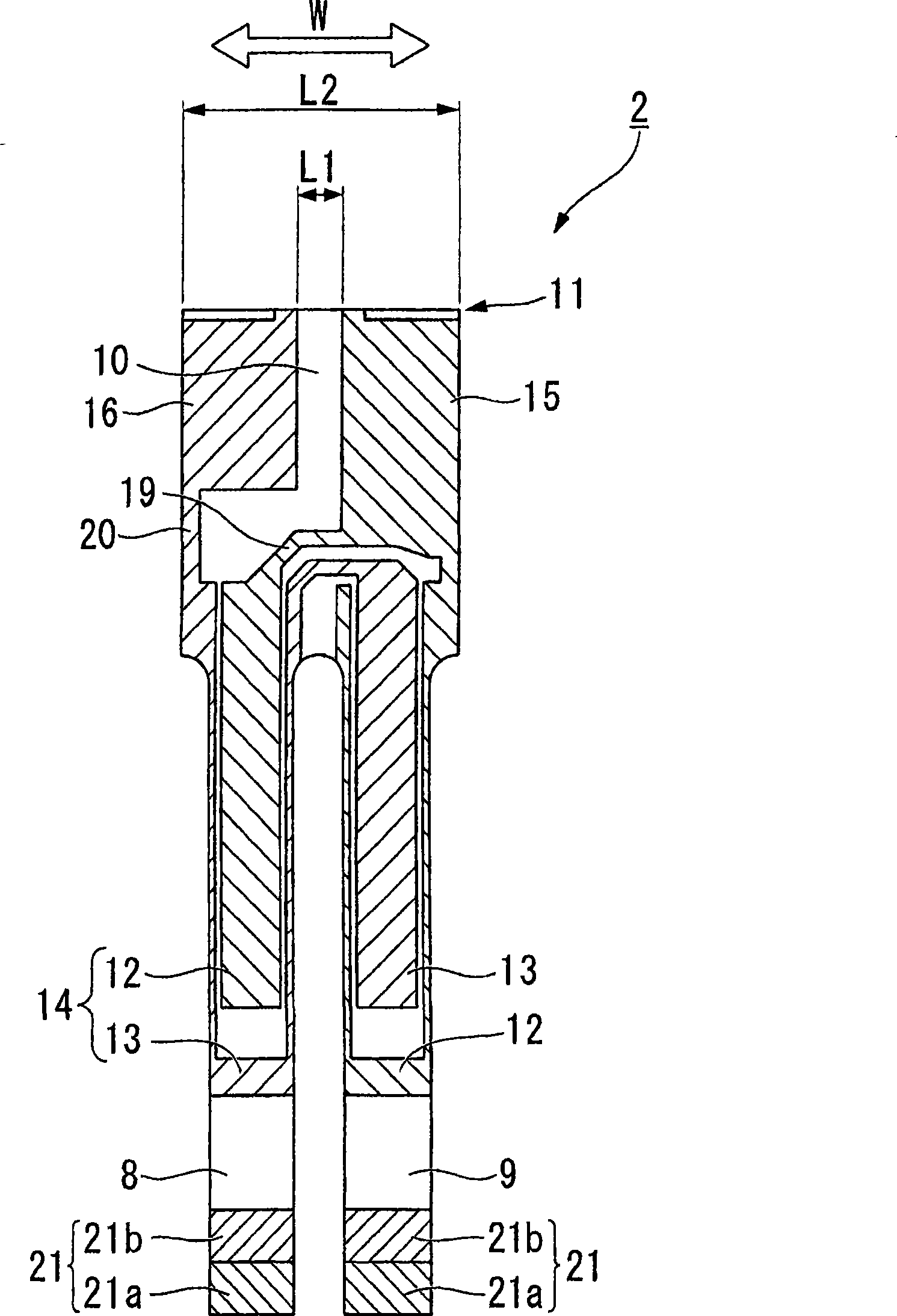

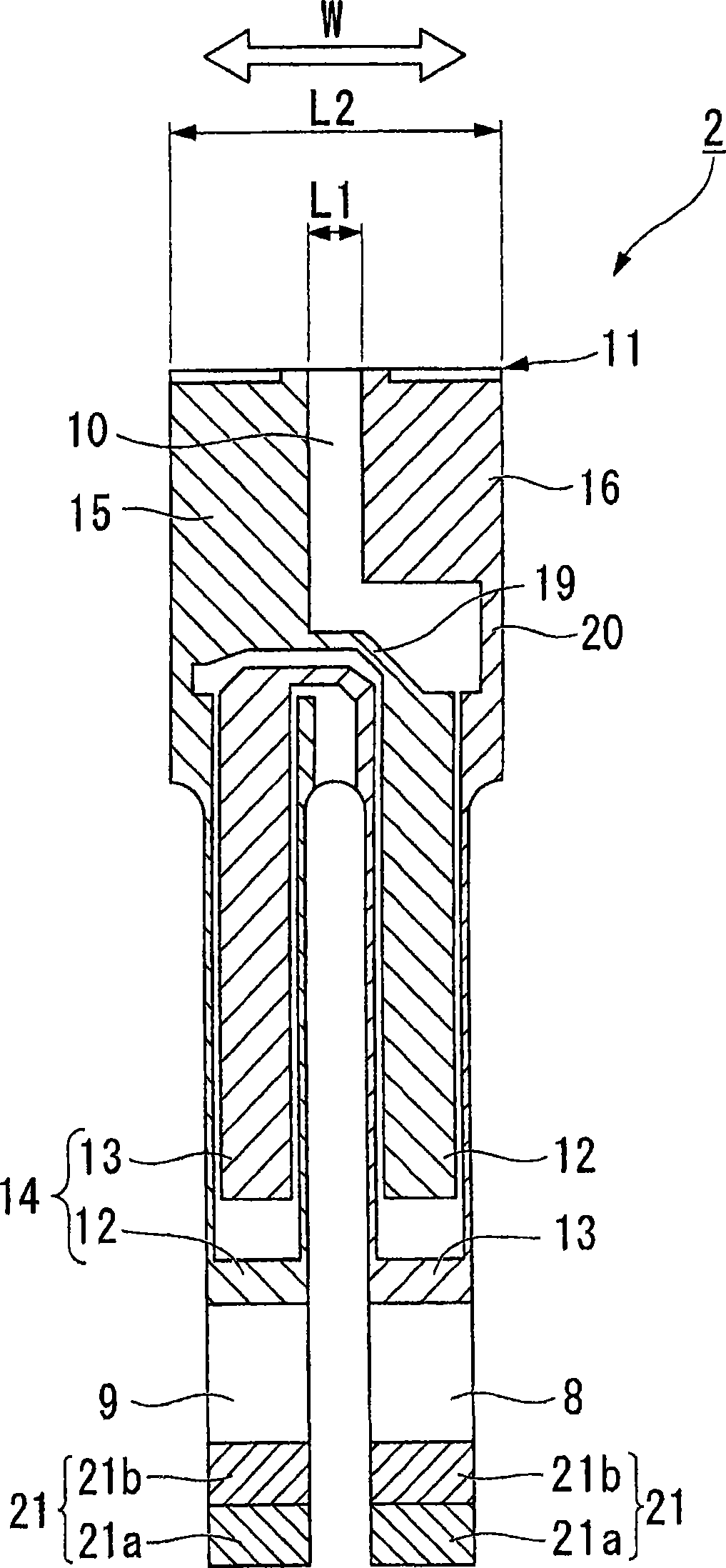

[0076] will refer to the following Figure 1 to Figure 11 The first embodiment according to the present invention is explained. Furthermore, according to this embodiment, as the piezoelectric vibrator 1 , an example of a cylindrical package type piezoelectric vibrator will be explained.

[0077] Such as Figure 1 to Figure 3 As shown, the piezoelectric vibrator 1 of this embodiment includes a piezoelectric vibrating piece 2, a housing 3 housing the piezoelectric vibrating piece 2 inside, and a plug 4 constituting an airtight terminal that hermetically seals the piezoelectric vibrating piece 2. The vibrating piece 2 is enclosed inside the housing 3 .

[0078] Such as figure 2 and image 3 As shown, the piezoelectric vibrating piece 2 is a tuning-fork type vibrating member formed of a piezoelectric material such as quartz, lithium tantalate, lithium niobate, etc., and vibrates when a predetermined voltage is applied thereto.

[0079] The piezoelectric vibrating piece 2 inc...

no. 2 example

[0124] Next, refer to Figure 12 A second embodiment according to the present invention is explained. In addition, in the second embodiment, the same parts as the constituent elements of the first embodiment are assigned the same symbols, and their descriptions are omitted.

[0125] The second embodiment differs from the first embodiment in the electrodes formed in the electrode forming step. That is, although according to the first embodiment, the pair of extension electrodes S2, S3 is simply formed, according to the second embodiment, a common extension electrode S4 is formed in addition to the pair of extension electrodes S2, S3.

[0126] Explaining in detail, according to this embodiment, in the electrode forming step, as Figure 12 As shown, a common extension electrode S4 is formed by electrically connecting a plurality of extension electrodes S2 on one side, respectively. That is, the common extension electrode S4 is formed in a state of conduction with all the mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com