Method for preparing glyphosate by oxidizing N-(Phosphonomethyl)iminodiacetic acid with active carbon as catalyst oxygen

A technology of oxygen oxidation and activated carbon, applied in chemical instruments and methods, botanical equipment and methods, physical/chemical process catalysts, etc., can solve expensive, uneconomical, complex and other problems, and achieve high conversion rate and selectivity , Reduce equipment investment, the effect of cost advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

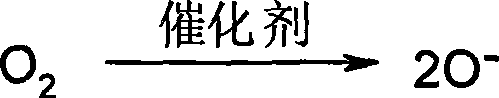

Method used

Image

Examples

Embodiment 1

[0056] The weight ratio of glyphosate: activated carbon: water is 1:0.04:12 and put into a 2-liter pressure reactor. The water is deionized water; the mass content of glyphosate is greater than 98%, and the specific surface area of activated carbon At 1000m 2 / g. Of course, the specific surface area of activated carbon can also be 800-1200m 2 Any value between / g, such as 850, 900, 950, 1050, 1100, 1150m 2 / g.

[0057] Close the pressure reactor and the inlet valve and outlet valve, stir and raise the temperature to 100°C, and introduce oxygen at 500ml / min, the reaction pressure is controlled at 0.5MPa, the reaction time is 60min, the conversion rate of glyphosate is detected to be 99.31%, and the oxygen supply is stopped. , Relieve the pressure to normal pressure. The catalyst activated carbon was recovered by filtration under the condition of maintaining a temperature of 75-80℃ (used as the next batch of oxidation catalyst feed), the reaction liquid was filtered to detect th...

Embodiment 2

[0059] The weight ratio of glyphosate to water is 1:12 and the catalyst recovered in Example 1 (and 5% (weight percent) of fresh catalyst activated carbon is added to the amount of catalyst activated carbon in Example 1) is put into a 2-liter pressure reactor , The water uses deionized water; the mass content of glyphosate is greater than 98%, and the specific surface area of activated carbon is 1000m 2 / g.

[0060] Close the pressure reactor and the inlet valve and outlet valve, stir and raise the temperature to 100°C, and introduce oxygen at 500ml / min, the reaction pressure is controlled at 0.5MPa, the reaction time is 60min, the conversion rate of glyphosate is detected to be 99.26%, and the oxygen supply is stopped. , Relieve the pressure to normal pressure. The catalyst activated carbon was filtered and recovered under the condition of maintaining the temperature of 75-80℃ (used as the next batch of oxidation reaction catalyst feed), the reaction liquid was filtered to dete...

Embodiment 3

[0062] The weight ratio of glyphosate to water was 1:12 and the catalyst recovered in Example 2 (and 5% (weight percent) of fresh catalyst activated carbon was added to the amount of catalyst activated carbon in Example 1) was put into a 2-liter pressure reactor , The water uses deionized water; the mass content of glyphosate is greater than 98%, and the specific surface area of activated carbon is 1000m 2 / g.

[0063] Close the pressure reactor and the inlet valve and outlet valve, stir and raise the temperature to 100°C, and introduce oxygen at 500ml / min, the reaction pressure is controlled at 0.5MPa, the reaction time is 60min, the conversion rate of glyphosate is detected to be 99.17%, and the oxygen supply is stopped. , Relieve the pressure to normal pressure. The catalyst activated carbon was filtered and recovered under the condition of maintaining the temperature of 75-80°C (used as the next batch of oxidation reaction catalyst feed), the reaction liquid was filtered to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com