Air-chamber jigger and coal separation method thereof

An air chamber and jig technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problem that the air chamber will be submerged or even the water will be discharged if the air time is too long, and the longitudinal wave height distribution of the sieve plate is not good. The problem of uniformity and uneven water flow in the jigging chamber can be achieved to avoid the phenomenon of running water, save raw materials, and reduce the occupied area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

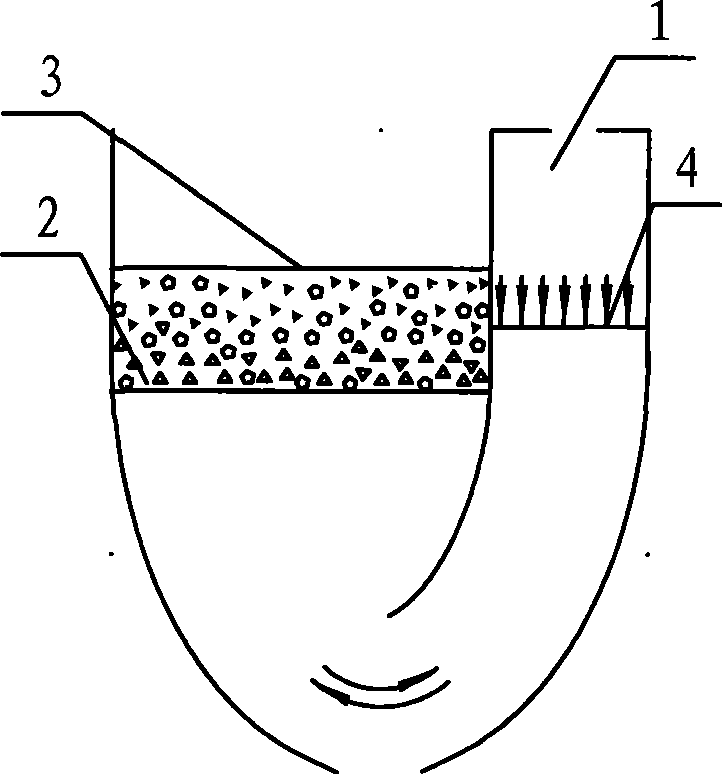

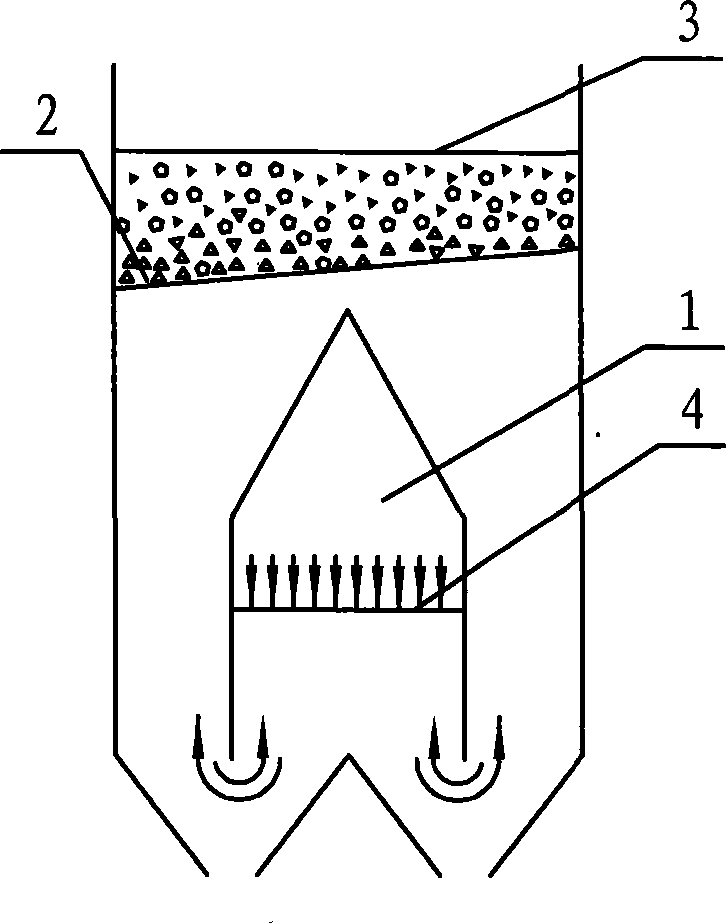

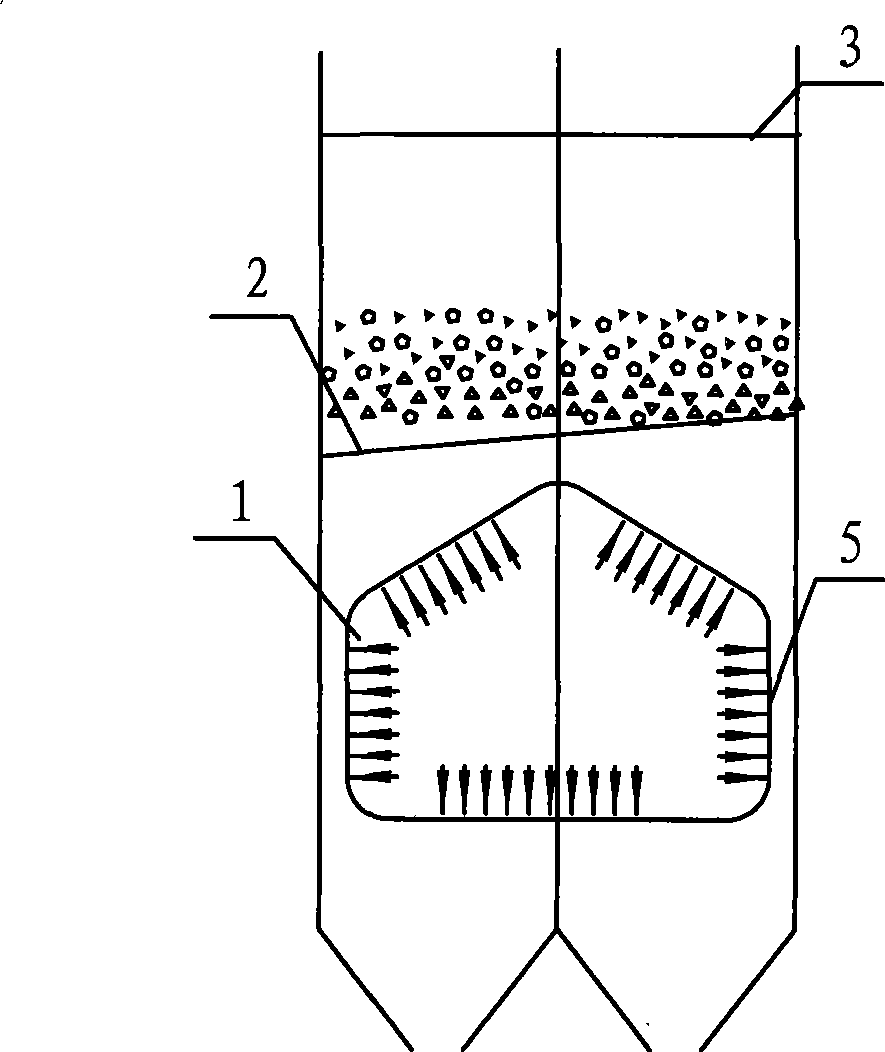

[0025] The present invention can provide various types of air pulsation jigs. In the embodiment, the air chamber jig composed of a sealed container that can change volume and shape is used for further description:

[0026] image 3 , 4 Among them, an air chamber jigger composed of a sealed container that can change volume and shape, it includes a common jig body and an air chamber 1 that can change volume and shape installed in the jigging chamber, and the air that can change volume and shape The chamber is an impermeable container, which can be made of soft materials, or rubber or plastic. The air chamber 1 is installed under the sieve plate 2, leaving an opening to connect with the pipeline, and the compressed air source is connected through the air inlet valve. Connected to the atmosphere through the exhaust valve. Above the sieve plate is the material bed to be sorted, and the water level line 3 does not pass through the bed. When the exhaust valve of the jig machine is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com