Printing process control method

A process control, bar code technology, applied in the direction of instruments, electrical components, collaborative devices, etc., can solve problems such as difficulty, batch scrapping, inability to form systems, etc., to prevent errors, improve risk prevention capabilities, and improve product quality. Effect

Active Publication Date: 2011-01-05

浙江华人数码科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In some high-end equipment such as glue binding machines and saddle stitching machines, there are expensive intelligent recognition devices, but they are generally based on image recognition, and the error correction methods between devices are different, so they cannot form a system. , cannot be linked with each other, in the printing industry due to practical limitations, the application is not widely

The usual problem is that when small-batch, multi-batch, and multi-single-number products become mainstream products, the differences between products are very small, sometimes even only 5‰. It is quite difficult to identify them manually. Big

In any of the above links, once a mistake is made, it will cause a batch loss accident, which will produce batch products that cannot be repaired, resulting in the loss of batch scrap

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

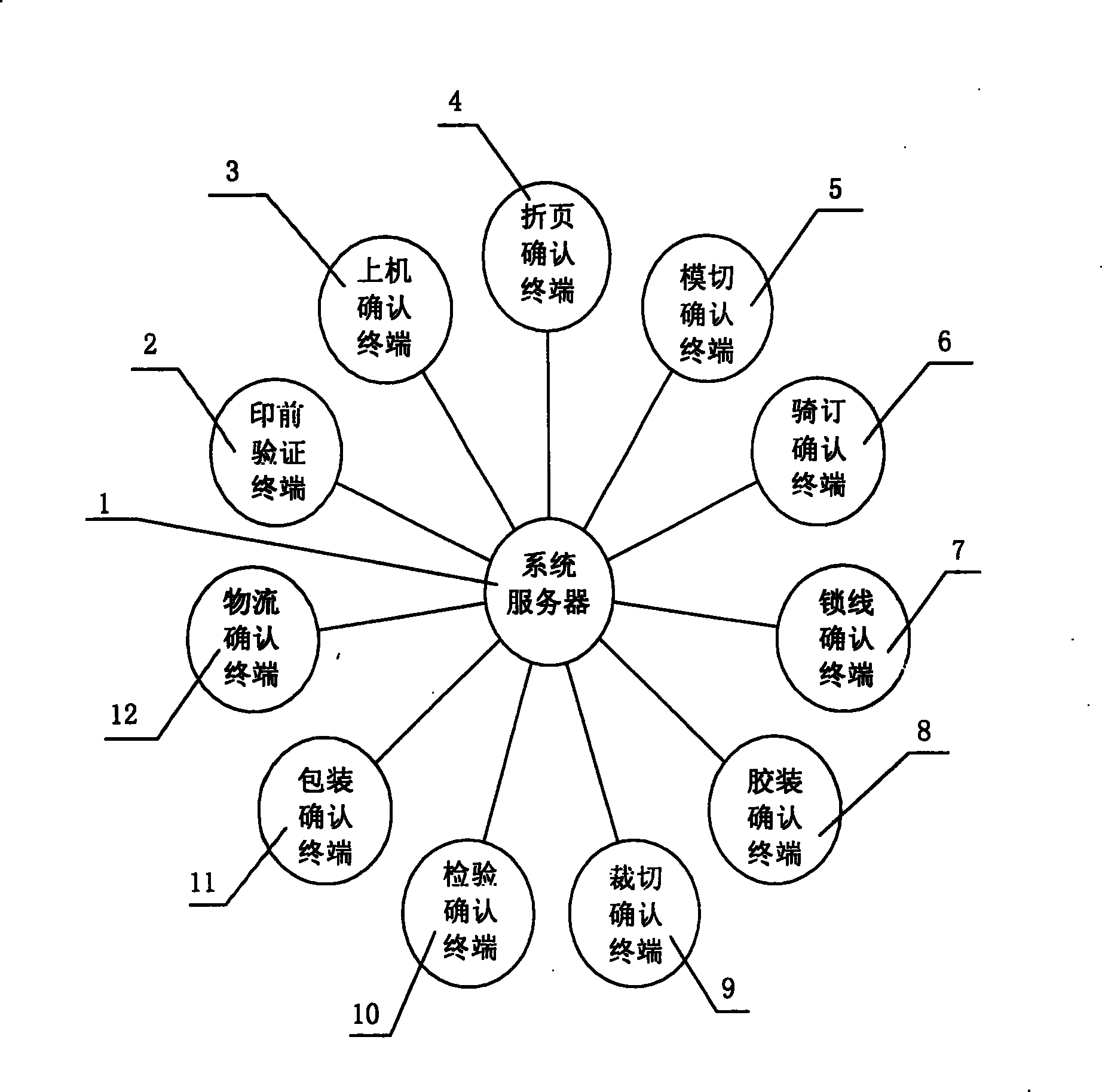

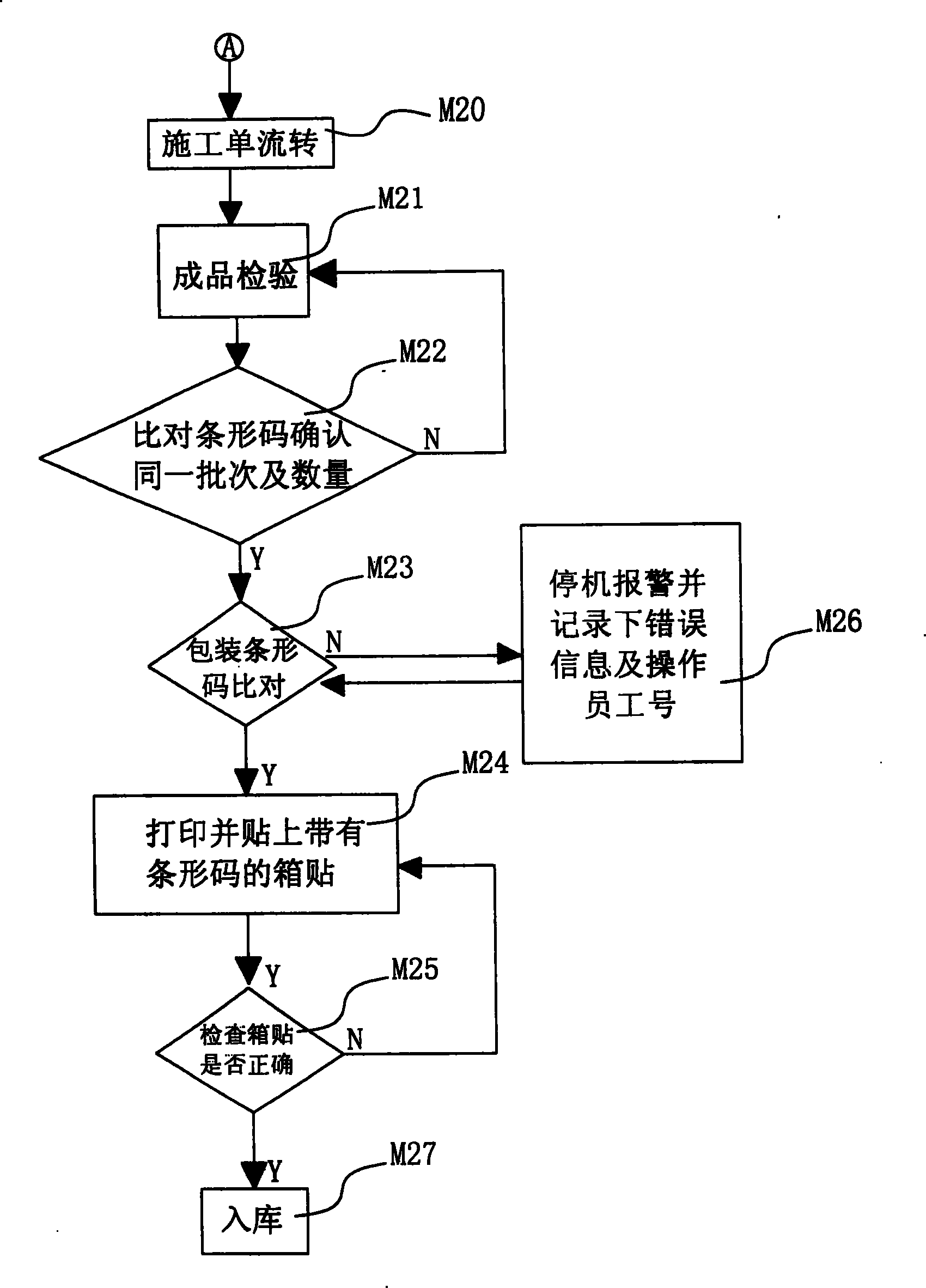

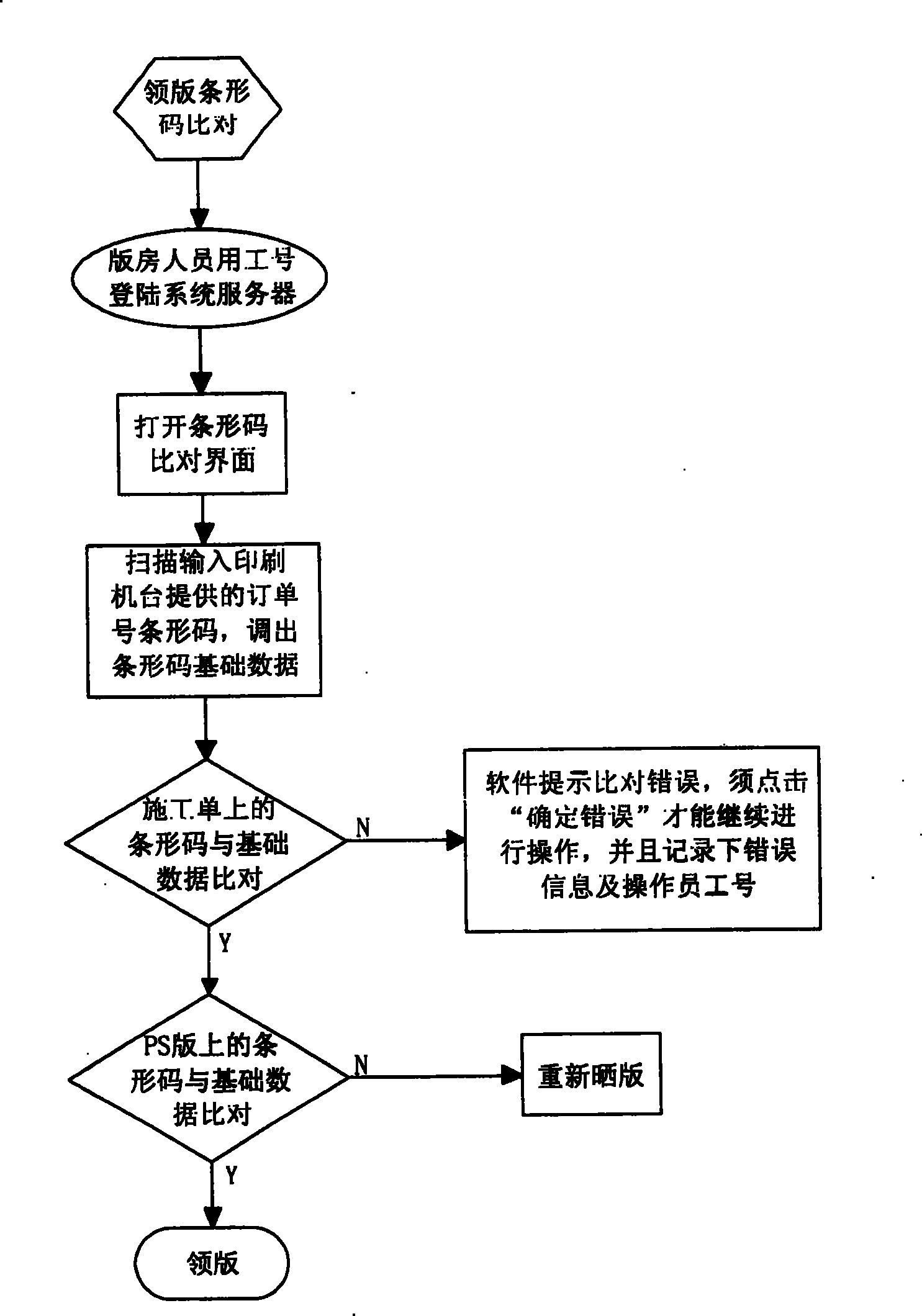

Login to View More Abstract

The invention relates to a system for controlling printing flow, and belongs to the technical field of printing management. A controlling method for preventing and correcting errors of the printing flow by a system server comprises the following steps: generating bar codes before printing; transporting the generated bar codes to a plate room for plate burning; receiving plates and comparing the bar codes; comparing the bar codes of four color plates before printing; printing; carrying out foldout online bar code comparison after completing the printing; according to the flow selection, carrying out riding online bar code comparison, cementing online bar code comparison or locking wire online bar code comparison; carrying out production inspection, and packaging; and printing and sticking a carton sticker with the bar code and entering a warehouse. By utilizing a bar code identification method and the image bearing property of the printing industry, exerting a database management mode,and combining the whole production flow of a printing enterprise, the system prevents the errors, realizes the implementation and control of the whole flow, radically changes the trouble that the printing enterprise carries out posttreatment only after the errors are found out, and improves the risk prevention capacity and the product quality of the enterprise.

Description

A printing process control method technical field The invention belongs to the technical field of printing management, and in particular relates to a printing process control method which uses barcodes to prevent errors in the production process of printing enterprises. Background technique The current status of the printing industry is that in the book printing industry, due to the problems of mixing materials, less materials, and more materials between products, product defects and large waste have been caused, which have not been well resolved. In the printing process, the physical transfer between pre-press, printing, post-press and other processes mainly relies on manual identification to judge whether there is an error between the film or PS plate, printed sheet or semi-finished product. In some high-end equipment such as glue binding machines and saddle stitching machines, there are expensive intelligent recognition devices, but they are generally based on image rec...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H04N1/00H04N1/32G06K17/00

Inventor 徐卫健魏兵蒋佳利吕达

Owner 浙江华人数码科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com