Novel technique for coproduction of 2-phosphonobutane-1,2,4-tricabroxylic acid and methyl chloride

A technology of phosphonobutane and phosphobutane, which is applied in the chemical industry, can solve problems such as non-existence, and achieve the effects of reducing costs, protecting the environment, and absorbing high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

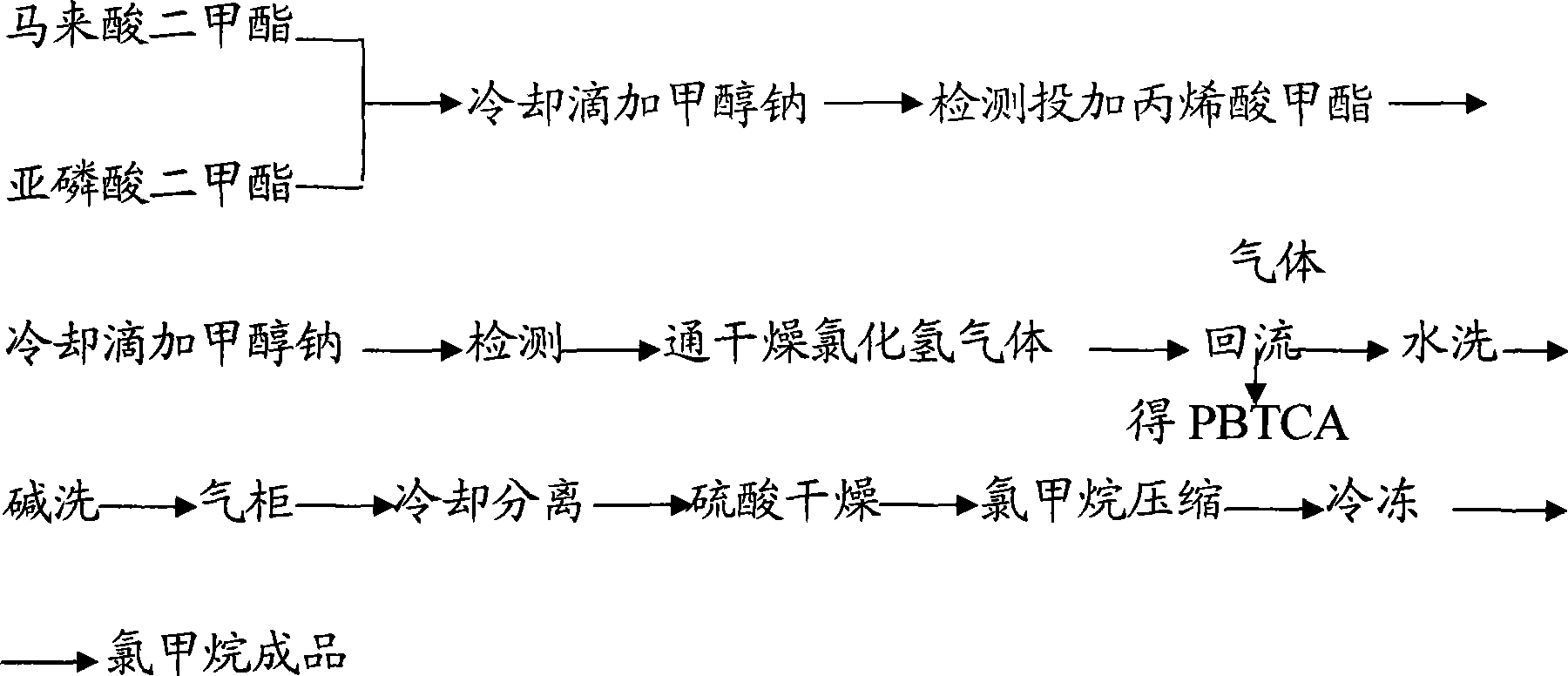

Method used

Image

Examples

Embodiment 1

[0024] (1) Put 700 kg of dimethyl maleate and 540 kg of dimethyl phosphite into the reaction kettle, open the main kettle to freeze brine, add 30 kg of sodium methoxide dropwise, control the dropping temperature at 30°C, and pass the test after dropping Semi-finished tetramethyl phosphonosuccinate;

[0025] (2) Add 560 kg of methyl acrylate to the above-mentioned qualified semi-finished tetramethyl phosphonosuccinate, add 40 kg of sodium methoxide dropwise after cooling, control the dropping temperature at 25°C, and obtain the qualified intermediate 2-phosphate after dropping Butane-1,2,4-tricarboxylic acid pentamethyl ester;

[0026] (3) Pass 1780 kg of hydrogen chloride gas into the above-mentioned qualified intermediate 2-phosphobutane-1,2,4-tricarboxylic acid pentamethyl ester, control the ventilation temperature at 50° C., reflux for 8 hours, and detect the product 2-phosphonobutane-1,2,4-tricarboxylic acid, simultaneously open the methyl chloride recovery unit, and cont...

Embodiment 2

[0032] (1) Put 700 kg of dimethyl maleate and 540 kg of dimethyl phosphite into the reaction kettle, open the main kettle to freeze brine, add 25 kg of sodium methoxide dropwise, control the dropping temperature at 50°C, and pass the test after dropping Semi-finished tetramethyl phosphonosuccinate;

[0033] (2) Add 550 kg of methyl acrylate to the above-mentioned qualified semi-finished tetramethyl phosphonosuccinate, add 35 kg of sodium methoxide dropwise after cooling, control the dropwise addition temperature at 50°C, and obtain the qualified intermediate 2-phosphate after dropping Butane-1,2,4-tricarboxylic acid pentamethyl ester;

[0034] (3) Pass 2150 kg of hydrogen chloride gas into the above-mentioned qualified intermediate 2-phosphobutane-1,2,4-tricarboxylic acid pentamethyl ester, control the ventilation temperature at 70° C., reflux for 9 hours, and detect the product 2-phosphonobutane-1,2,4-tricarboxylic acid, simultaneously open the methyl chloride recovery unit,...

Embodiment 3

[0040] (1) Put 700 kg of dimethyl maleate and 540 kg of dimethyl phosphite into the reaction kettle, open the main kettle to freeze the brine, add 37 kg of sodium methoxide dropwise, control the dropwise addition temperature at 70°C, and pass the test after dropping Semi-finished tetramethyl phosphonosuccinate;

[0041] (2) Add 630 kg of methyl acrylate to the above-mentioned qualified semi-finished tetramethyl phosphonosuccinate, add dropwise 56 kg of sodium methoxide after cooling, control the dropping temperature at 80°C, and obtain the qualified intermediate 2-phosphate after dropping Butane-1,2,4-tricarboxylic acid pentamethyl ester;

[0042] (3) Pass 2150 kilograms of hydrogen chloride gas into the intermediate 2-phosphobutane-1,2,4-tricarboxylate pentamethyl ester that has passed the above detection, control the ventilation temperature at 80° C., reflux for 10 hours, and detect the product 2-phosphonobutane-1,2,4-tricarboxylic acid, simultaneously open the methyl chlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com