Double-ended semiautomatic tapping machine of connecting piece

A connecting piece and semi-automatic technology, applied in the direction of thread cutting machine, metal processing machinery parts, large fixed members, etc., can solve the problems of low production efficiency and poor operation safety, so as to improve work efficiency, improve safety, and reduce worker labor The effect of operating strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

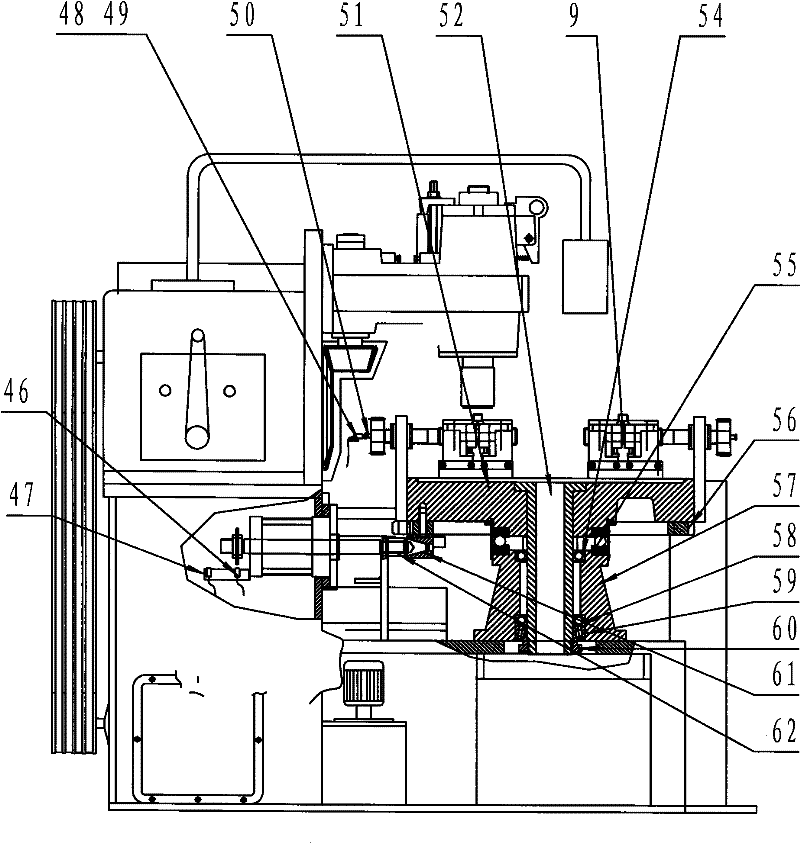

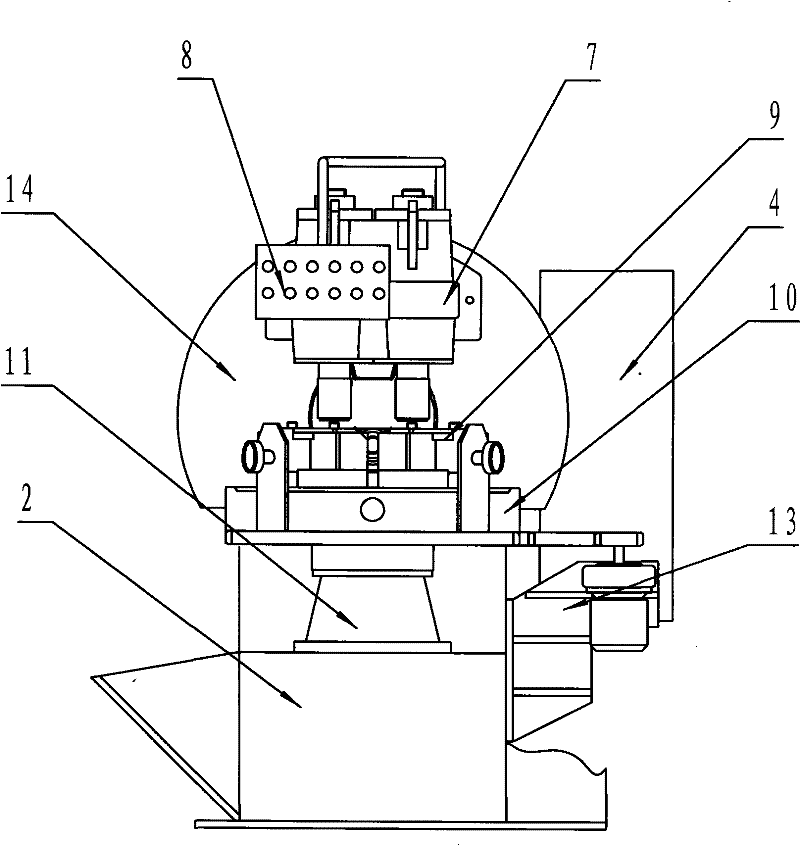

[0021] Embodiment 1, a double-head semi-automatic tapping machine for pipeline connectors, is characterized in that it mainly includes the following part of the bed 2 and a tapping system installed on the bed,

[0022] The rotary table 10 with the workpiece fixture installed,

[0023] Tapping, mounting workpiece and rotary table operation control device,

[0024] The bottom of the bed is equipped with a motor 1, a cooling water pump 3, a gearbox 5 on the top of the bed, a switchboard 6 on one side, and a screw rack mounting plate 14 with a double-ended screw rack 7 at the front of the gearbox , the front end of the main shaft of the gearbox is equipped with a bevel gear connected to the bevel gear at the bottom of the double-headed screw frame, and there is a control button box 8 in front of the screw frame.

[0025] The rotary table includes a rotary table support 11 and three sets of combined fixtures 9 installed on the worktable, a rotary drive device 13 for the worktable,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com